What are Axial Fans? Where are They Used?

In the demanding environments of industrial facilities, achieving optimal energy efficiency is paramount for controlling operational costs and ensuring sustainability. A frequently overlooked yet critical component in this equation is the correct resistance connection within cooling systems. Improper resistor installation safety practices can lead to significant energy waste, increased electrical strain on compressors and fans, and premature system failure. This guide outlines how meticulous installation directly translates to lower kilowatt-hour consumption and a more robust reliable cooling infrastructure, forming the foundation for long-term operational savings.

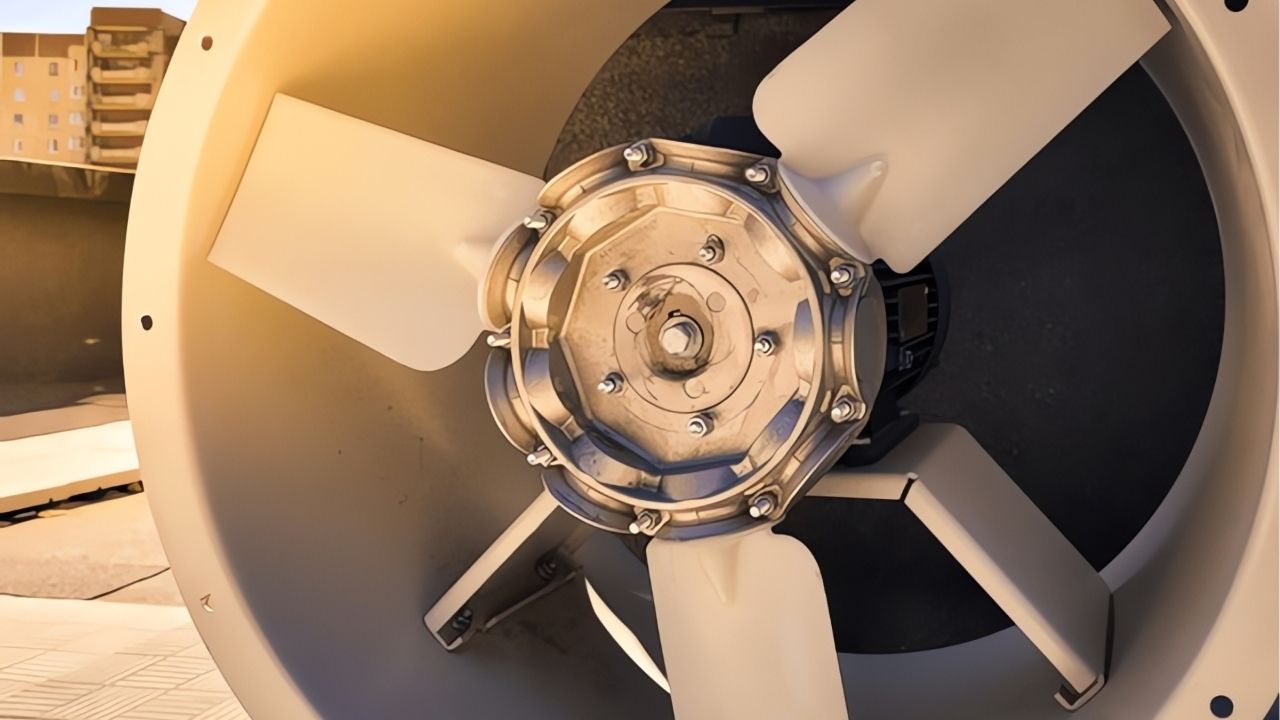

The principle behind this efficiency gain lies in electrical stability. A properly installed resistor ensures that auxiliary components, such as those in durable evaporator condenser production units, receive a consistent and precise electrical signal. This prevents power fluctuations that force motors to work harder, thus reducing the overall energy draw of the system. For components like the custom axial fan application, this stability is crucial; an erratic signal can diminish airflow and heat exchange efficiency, directly impacting the cooling capacity and forcing the system to run longer cycles. Adhering to a strict resistor installation safety guide is therefore not just a protective measure but a direct investment in performance.

This technical precision is a hallmark of Günay Soğutma expert solutions, where disciplined manufacturing ensures that every component, including resistors, is engineered for seamless integration. The capability for both serial production and custom production allows for the creation of systems perfectly tailored to specific industrial loads, whether for a food processing line requiring precise temperature control or an energy sector plant needing robust heat rejection. This integration minimizes electrical resistance at connection points, a key factor in achieving an energy-efficient resistor connection that supports the entire cooling circuit.

Ultimately, the focus on proper resistor installation is a core aspect of proactive industrial cooling system maintenance. By eliminating a common source of electrical inefficiency, facilities can dramatically reduce energy costs, extend the operational life of expensive compressors and fans, and minimize unplanned downtime. This approach, supported by high-quality components from established manufacturers, transforms the cooling system from a utility cost center into a strategic asset for production reliability and long-term financial performance, ensuring that every kilowatt of energy is utilized for maximum cooling effect.

Unplanned downtime in industrial cooling is a costly event, often stemming from preventable electrical failures. A primary defense against such disruptions is a rigorous resistor installation safety guide focused on achieving a perfect correct resistance connection. Loose terminals, corrosion, or thermal overload can cascade into system-wide issues, compromising the reliable cooling infrastructure that production lines depend on. This guide establishes the critical link between meticulous electrical practices and the uninterrupted, durable industrial cooling performance required in high-stakes environments.

The consequences of neglecting connection safety are severe. An insecure resistor connection generates excessive heat, increasing resistance and creating a vicious cycle that can damage sensitive control boards and degrade adjacent components. This is particularly detrimental to systems featuring durable evaporator condenser production units, where stable electrical input is essential for precise pressure and temperature control. Similarly, a fault in the circuit governing a custom axial fan application can lead to reduced airflow, causing compressor strain and elevating the risk of a catastrophic shutdown. Proactive industrial cooling system maintenance must therefore prioritize electrical integrity.

Implementing a robust safety protocol is a core principle behind Günay Soğutma expert solutions, where disciplined manufacturing ensures components are built for longevity and safe integration. The flexibility of both serial production for standard applications and custom production for unique facility needs guarantees that resistors are correctly specified for their electrical load. This precision engineering is fundamental to an energy-efficient resistor connection, as it minimizes power loss and heat generation at the source.

By adhering to these safety principles, facility managers transform their cooling systems from a vulnerability into a pillar of operational reliability. The direct outcomes are a significant reduction in maintenance emergencies, extended equipment lifecycle, and consistent cooling capacity that protects production quality. Investing in correctly installed, high-quality components is the most effective strategy for safeguarding against downtime, ensuring that your cooling infrastructure performs reliably under the most demanding conditions, year after year.

Common resistor installation safety guide violations, such as overtightened terminals or incorrect wattage selection, create immediate and long-term financial drains for industrial facilities. These errors prevent a correct resistance connection, leading to chronic inefficiencies that undermine even the most robust reliable cooling infrastructure. The result is a continuous cycle of wasted energy, emergency repairs, and compromised cooling performance that directly impacts production throughput and operational budgets.

One critical mistake is the mismatching of resistor specifications to the load requirements of key components like those in durable evaporator condenser production systems. An undersized resistor will overheat and fail prematurely, while an oversized one can cause improper cycling of fan motors. This is especially damaging in a custom axial fan application, where precise speed control is essential for optimal heat exchange. Such errors transform routine industrial cooling system maintenance into a frequent, costly firefighting exercise, eroding the system's designed efficiency and durability.

Günay Soğutma expert solutions address these pitfalls at the source through disciplined engineering and manufacturing. The company's approach, leveraging both serial production consistency and custom production adaptability, ensures that every resistor is precisely matched to its intended circuit. This eliminates guesswork and improper sizing, which is foundational to achieving a stable, energy-efficient resistor connection that performs reliably under continuous industrial loads.

By specifying components engineered to prevent common installation errors, facilities can break the cycle of reactive repairs and energy waste. The outcome is a cooling system characterized by predictable performance, significantly reduced operational expenses, and extended equipment service life. Partnering with manufacturers who prioritize precision in both component design and integration guidance is the most effective strategy for turning a potential liability into a cornerstone of durable, cost-effective industrial cooling.

A comprehensive resistor installation safety guide is not merely a procedural document but a strategic asset for protecting capital-intensive cooling equipment. The goal is to achieve a flawless correct resistance connection that safeguards the entire system from electrical faults, thereby ensuring the long-term reliability required for continuous industrial operations. This proactive approach directly translates to significantly reduced operational costs by preventing energy waste and catastrophic component failures that necessitate expensive emergency repairs and production halts.

The core of this protection lies in understanding how a single point of failure can destabilize an entire system. An unsafe resistor connection generates excessive heat, which degrades insulation and can lead to short circuits. This poses a particular risk to sophisticated components from durable evaporator condenser production lines, where precise thermal management is critical. In applications involving a custom axial fan application, an electrical fault can disrupt airflow balance, causing inefficient heat rejection and forcing compressors to overwork. Integrating safety protocols into standard industrial cooling system maintenance routines is therefore essential for preserving system integrity.

This disciplined methodology is exemplified by Günay Soğutma expert solutions, where the integration of modern technology with rigorous manufacturing standards produces components designed for safety and endurance. The company's capability for both high-volume serial production and tailored custom production ensures that every resistor is application-matched, which is the first step toward an inherently energy-efficient resistor connection. This precision engineering minimizes parasitic power loss and thermal stress, contributing directly to a more stable and efficient reliable cooling infrastructure.

Ultimately, viewing resistor safety through the lens of risk mitigation and total cost of ownership empowers facility managers to make smarter investments. By prioritizing components and installation practices that prevent failures before they occur, businesses secure uninterrupted production, maximize the lifespan of their cooling assets, and achieve a lower overall cost of operation. This strategic focus on electrical safety is a fundamental pillar for building a cooling infrastructure that delivers unwavering performance and financial predictability.

A systematic approach to electrical integration is fundamental to achieving maximum cooling system lifespan and substantial energy savings in demanding industrial applications. This begins with a meticulous, step-by-step procedure grounded in a professional resistor installation safety guide. The objective is a perfect correct resistance connection that eliminates power loss, minimizes heat generation, and ensures the stable operation essential for a reliable cooling infrastructure. Each step, from specification to torque verification, directly influences long-term operational costs and equipment durability.

The first critical step is selecting a resistor with the exact specifications for the intended load. This is particularly vital for protecting components from durable evaporator condenser production units, where incorrect resistance can lead to erratic valve operation and inefficient heat transfer. For systems utilizing a custom axial fan application, precise resistor matching ensures accurate speed control, which is crucial for maintaining designed airflow and static pressure without overloading the motor. This precision selection is a cornerstone of preventative industrial cooling system maintenance, preventing inefficiencies at the source.

The installation process itself demands discipline. Proper terminal preparation, correct torque application, and the use of anti-oxidation compounds are non-negotiable for creating an energy-efficient resistor connection. These practices, which are standard in Günay Soğutma expert solutions, ensure minimal electrical resistance at the junction point. The company's disciplined approach, supported by both serial production for consistency and custom production for specific challenges, guarantees that components are not only high-quality but also perfectly suited for a seamless and reliable integration.

By following this professional protocol, facilities achieve a dual victory dramatic reductions in energy consumption due to minimized electrical losses and a significant extension of the cooling system's operational life. This methodical investment in installation quality transforms the resistor from a simple component into a key contributor to system-wide efficiency and reliability, delivering measurable returns through lower utility bills and deferred capital expenditure on premature equipment replacements.

The choice between standard and custom resistor installation is a strategic decision that directly impacts the durability and efficiency of your production line's cooling system. While off-the-shelf components offer simplicity, a tailored approach often delivers superior performance by ensuring a perfect correct resistance connection for specific operational demands. This alignment is critical for building a truly reliable cooling infrastructure that can withstand unique environmental stresses and load profiles, ultimately determining long-term energy consumption and maintenance frequency.

Standard resistors are suitable for applications with common, predictable electrical characteristics. However, in complex systems featuring components from durable evaporator condenser production lines or specialized setups like a custom axial fan application, a one-size-fits-all solution can be inadequate. An incorrectly specified resistor may lead to improper motor speeds or control signal fluctuations, forcing the system to operate outside its ideal efficiency band. This undermines the goals of proactive industrial cooling system maintenance and can prevent achieving an energy-efficient resistor connection.

This is where the flexibility of manufacturers offering both paths becomes invaluable. Günay Soğutma expert solutions, for instance, provide the economies of scale through disciplined serial production for standard needs, while their engineered custom production capability addresses unique challenges. A custom resistor is designed to match the exact electrical load, ambient conditions, and performance requirements of the application, a level of precision that standard components cannot guarantee. This tailored approach is a core principle of any comprehensive resistor installation safety guide, prioritizing optimal performance over mere compatibility.

For facilities seeking to maximize return on investment, the custom path typically leads to greater gains in both efficiency and equipment lifespan. The initial investment in a perfectly matched component pays dividends through reduced energy waste, lower incidence of failure, and extended service life for expensive cooling assets. By choosing a solution engineered for your specific production line, you transform the cooling system from a generic utility into a finely tuned asset that actively contributes to operational reliability and cost control.

Optimizing electrical connections within industrial cooling systems is a direct pathway to achieving a sustainable ROI and significantly lower expenses. This process begins with a meticulous focus on creating an energy-efficient resistor connection, which minimizes parasitic power loss and thermal stress. Adhering to a rigorous resistor installation safety guide ensures that this optimization is not only effective but also durable, forming the bedrock of a reliable cooling infrastructure that delivers consistent performance under full load.

The technical methodology for optimization involves precise specification and installation to achieve a perfect correct resistance connection. This is especially critical when integrating with high-performance components from durable evaporator condenser production systems, where stable electrical signals are necessary for accurate pressure and temperature control. In a custom axial fan application, an optimized resistor ensures the fan motor receives clean power, enabling it to operate at its peak efficiency curve without unnecessary energy expenditure. This level of precision elevates standard industrial cooling system maintenance into a strategic efficiency-enhancing practice.

The principles of optimization are central to Günay Soğutma expert solutions, where a disciplined manufacturing process guarantees component quality and performance. The strategic use of serial production for standardized reliability, combined with the flexibility of custom production for application-specific challenges, ensures that every resistor contributes to system-wide efficiency. This engineered approach eliminates the guesswork and compromises that often lead to energy waste and premature component failure in less optimized systems.

By implementing these optimization techniques, industrial facilities can transform their cooling operations from a significant cost center into a model of efficiency. The result is a continuous reduction in kilowatt-hour consumption, extended operational life for major components like compressors and fans, and a dramatic decrease in unplanned downtime. This proactive investment in connection quality delivers a compounding financial return, solidifying the cooling system's role as a key contributor to both production reliability and overall profitability.

Fill out the form to discover the most suitable high-end products for your projects. Contact Us Now.