Media

Strong Connections Through Fair Participation

Hostech 2025

This year, Hostech by TUSİD 2025 was held on May 27–31 at the Istanbul TÜYAP Fair and Congress Center. As Turkey’s largest and Europe’s second largest HORECA fair, it welcomed approximately 35,000 visitors from 140 countries across a 45,000 m⊃2; exhibition area. Günay Soğutma proudly took part in this major event. At our booth, we showcased our innovative industrial cooling products and sustainable solutions, while also connecting with professionals from both Turkey and abroad. For us, Hostech was more than just a fair; it was a valuable opportunity to build new business partnerships, strengthen existing relationships, and represent our company more powerfully in the international market. The strong interest from foreign buyer delegations once again proved that we are on the right track. We sincerely thank all our visitors and look forward to meeting again at upcoming fairs.

Read More

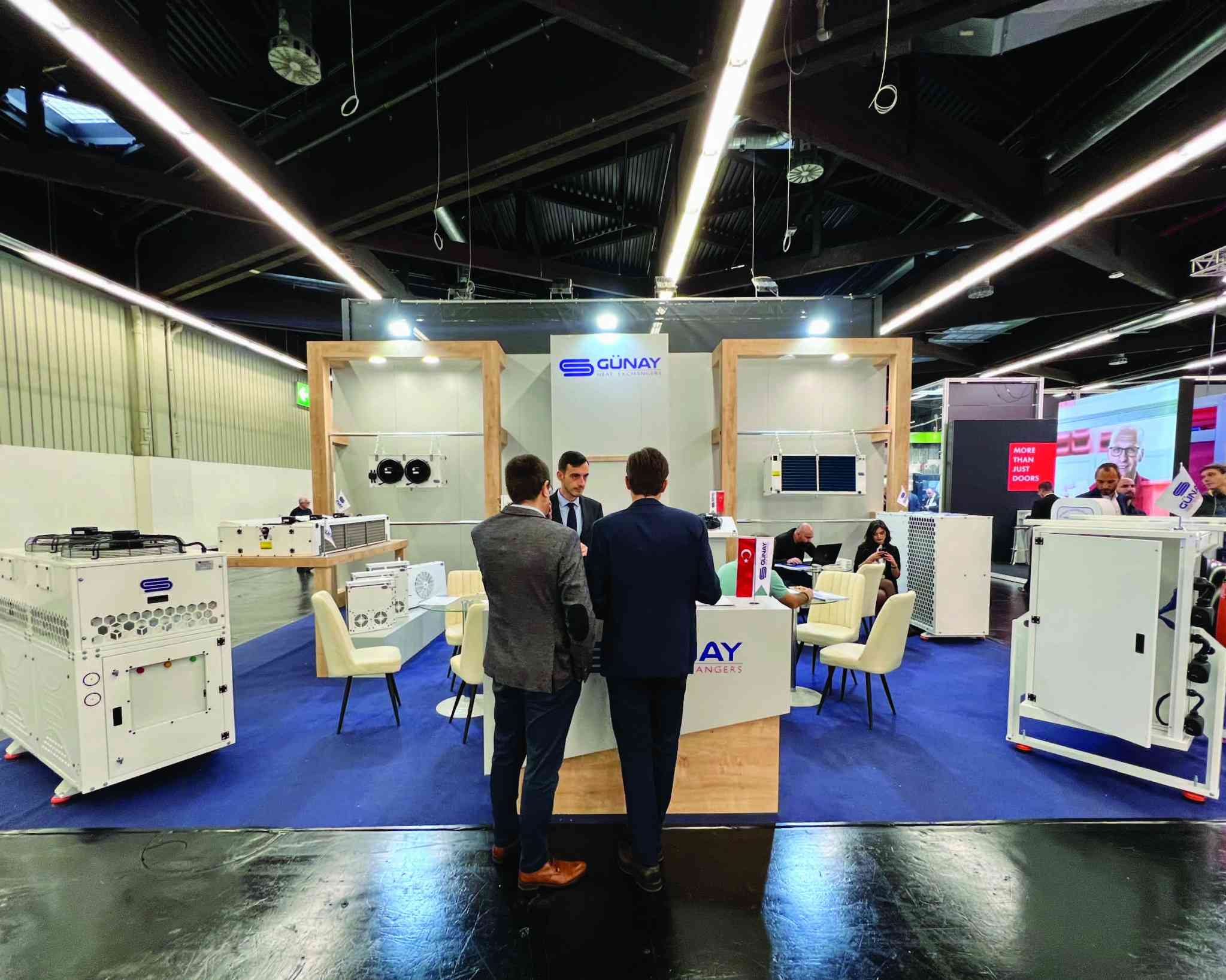

Chillventa 2022

Thank You to Everyone Who Joined Us at Chillventa 2022! We would like to extend our heartfelt thanks to all participants and valued customers who visited our stand at Chillventa 2022. Your interest and the time you shared with us were a tremendous source of motivation, allowing us to present our innovative cooling solutions and share our vision within the industry. The connections we have built with you strengthen our leadership goals and inspire us to provide more efficient and sustainable solutions in the future. We look forward to building new projects and strong partnerships together!

Read More

Chillventa 2024

Günay Soğutma participated in the Chillventa 2024 Fair, seizing the opportunity to showcase the latest innovations in the sector. During the event, we shared our newest technologies and solutions in the field of cooling and air conditioning with attendees. The fair served as an important platform to connect with industry professionals and foster new collaborations. Visitors had the chance to explore our innovative products and sustainable solutions while gaining insight into our customer-oriented approach. Chillventa 2024 provided not only an opportunity for knowledge exchange but also a chance to keep up with the latest industry trends. We are pleased to have established new business connections and strengthened existing relationships through this experience. We would like to extend our gratitude to all the visitors who joined us at the fair. We eagerly look forward to meeting you again at future events!

Read More

HVAC-R Egypt Expo 2024

With the solutions we presented at HVAC-R EGYPT EXPO, we reinforced our reliability and sustainability principles in the refrigeration and heat transfer sector in Egypt.

Read More

HVAC-R London 2023

HVAC Refrigeration Live, as an important event in the industry, offered a very valuable experience for us. We would like to express our sincere thanks to all exhibitors and customers who visited our booth for their interest and time. The strong ties we have established with you give us great motivation to maintain our leadership in the industry and to carry our solution-oriented approach even further.

Read More

ISK-SODEX Istanbul 2023

We participated in ISK-SODEX 2023, one of the leading exhibitions of the air conditioning industry. We would like to thank all our customers and exhibitors who showed great interest in our stand.

Read More

AquaTherm Exhibition 2023

Thank you to all our customers and exhibitors who visited our booth at AquaTherm Exhibition 2023. Your intense interest made us very happy and we were proud to share our innovations in the sector.

Read More

C&R Madrid 2023

The C&R Madrid 2023 fair was an unforgettable experience for us as an important event in the industry. We extend our heartfelt thanks to all participants and customers who visited our stand for their interest and time. The connections we established with you inspire us to continue our leadership in the industry and strengthen our solution-oriented approach. We look forward to building a more efficient and sustainable future togethe

Read MoreBlog

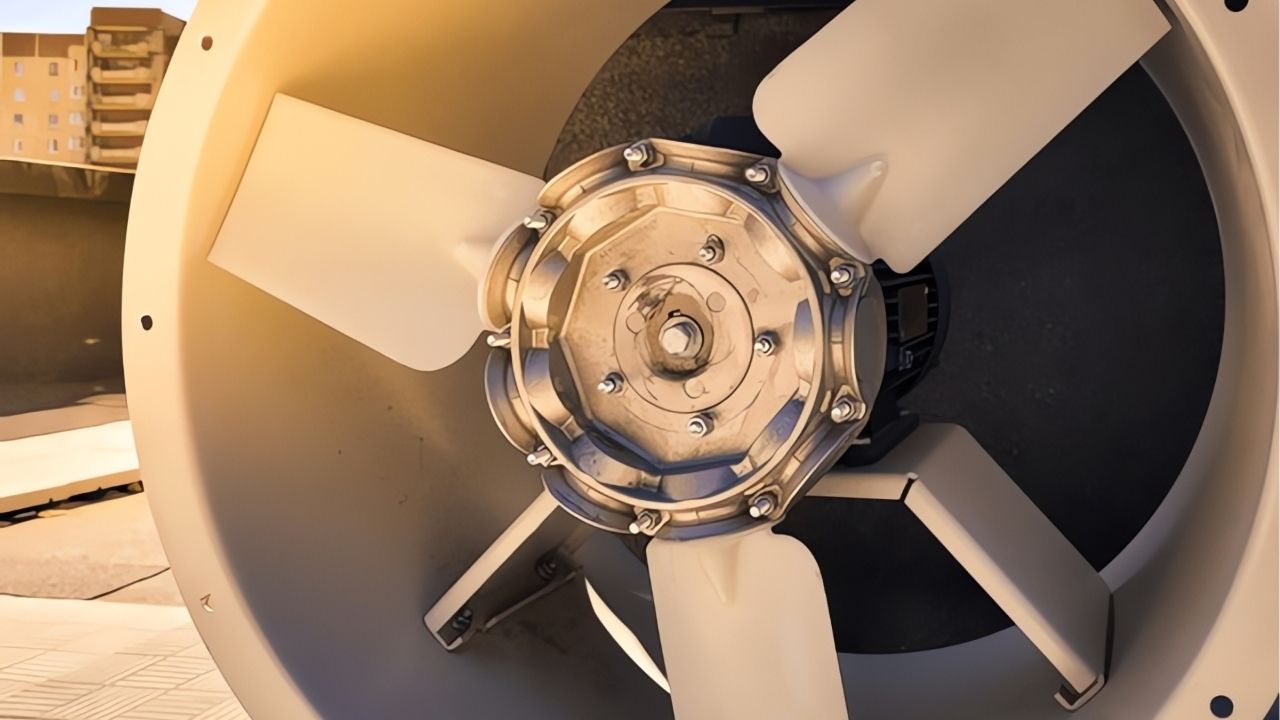

What are Axial Fans? Where are They Used?

What Are Axial Fans In Industrial Cooling Systems In the demanding environment of industrial cooling, maintaining optimal temperatures for processes and equipment is a constant challenge that directly impacts energy consumption and production reliability. A critical component in overcoming this challenge is the axial fan, an engineered solution designed to move large volumes of air efficiently. Its role is foundational to systems designed for high efficiency, offering a direct path to reducing operational costs and enhancing system performance. The fundamental design of an axial fan, where air flows parallel to the shaft, provides superior airflow with lower power requirements compared to other fan types. This aerodynamic efficiency is crucial for achieving durable fan design that stands up to continuous operation. For manufacturers like Günay Soğutma, engineering these fans involves a commitment to precision, utilizing advanced materials and manufacturing discipline to ensure longevity and reliability. This results in high efficiency fans that are integral to robust cooling infrastructure. Axial fans are not a one-size-fits-all solution; specific applications demand tailored performance. This is where the capability for custom axial fans becomes invaluable. In food sector cooling, for instance, fans must meet stringent hygiene standards while providing consistent airflow in refrigerated storage or processing areas. Similarly, energy facility ventilation requires fans capable of operating in harsh environments, often paired with heat exchangers in condenser production lines to reject heat effectively. Ultimately, selecting the right axial fan is an investment in operational stability and cost management. Günay Soğutma’s expertise in both serial and custom production ensures that facilities receive components perfectly matched to their specific cooling load and environmental conditions. This approach minimizes maintenance downtime and maximizes high efficiency, translating into significant energy savings and extended equipment life. By strengthening your cooling infrastructure with purpose-built axial fans, you achieve a more reliable, sustainable, and economically sound production environment. How To Select The Right Axial Fan For Your Facility Selecting the ideal axial fan is a critical engineering decision that directly defines the efficiency and reliability of your industrial cooling infrastructure. An improperly sized or specified fan can lead to excessive energy consumption, insufficient airflow, and premature component failure, undermining process stability and profitability. A methodical selection process ensures your investment delivers optimal performance, energy savings, and long-term operational resilience. The foundation of selection is a precise calculation of airflow requirements and static pressure specific to your application, whether for general facility ventilation or critical condenser production cooling. This technical assessment prevents the common pitfalls of underperformance and over-engineering. For specialized needs, such as corrosive environments in energy facility ventilation or hygienic air movement for food sector cooling, opting for custom axial fans is essential to meet stringent operational standards. Beyond performance metrics, prioritizing a durable fan design is non-negotiable for minimizing maintenance downtime and extending service life. This involves evaluating materials, blade geometry, motor quality, and bearing systems engineered for continuous duty. Günay Soğutma specializes in manufacturing high efficiency fans that incorporate modern technology to deliver superior airflow with lower power consumption, a key factor in achieving a rapid return on investment. Ultimately, partnering with a proven manufacturer who offers both serial and custom production capabilities guarantees a perfect fit for your facility's unique demands. This strategic approach transforms your axial fan from a simple component into a cornerstone of a robust, energy-efficient cooling system. By choosing a solution aligned with disciplined manufacturing principles, you secure not just immediate cooling performance but also long-term reliability and significant operational cost reductions. Where Are Axial Fans Used In Food Industry Cooling Maintaining precise temperature control is a foundational requirement in food sector cooling, directly impacting product safety, quality, and shelf life. The axial fan is a cornerstone of this critical industrial cooling infrastructure, providing the high-volume airflow necessary for efficient heat exchange in refrigeration units and cold storage facilities. Selecting the right fan technology directly influences energy consumption, operational reliability, and compliance with stringent hygiene standards. Within a food processing plant, axial fans are deployed in several key applications. They are essential for moving large volumes of cold air across evaporator coils in blast chillers and large-scale refrigerated warehouses, ensuring rapid and uniform cooling. These fans are also integral to the condenser production process for refrigeration systems, where they reject heat efficiently to the environment. For these demanding roles, high efficiency fans with a durable fan design are non-negotiable to withstand constant operation and humid, corrosive conditions. Off-the-shelf solutions often fall short in meeting the unique demands of food industry environments. This is where the capability for custom axial fans becomes a significant advantage. Manufacturers like Günay Soğutma design fans with specific features such as corrosion-resistant coatings, easy-clean surfaces, and IP-rated motors to endure washdown procedures and prevent contamination. This tailored approach ensures compatibility with the rigorous demands of food sector cooling, differentiating it from standard energy facility ventilation applications. By integrating purpose-built axial fans into your cooling infrastructure, you achieve more than just temperature control. You invest in a system designed for minimal maintenance downtime and optimal energy performance. Partnering with a disciplined manufacturer ensures that every component, from the fan blades to the motor housing, is engineered for longevity and reliability. This strategic focus on durable, high-efficiency cooling technology translates directly into lower operational costs, extended equipment life, and enhanced production security for your facility. What Makes An Industrial Axial Fan High Efficiency The pursuit of high efficiency in industrial cooling is a critical driver for reducing operational costs and enhancing system performance. An axial fan earns its designation as a high efficiency fan not from a single feature, but from a synergistic combination of advanced aerodynamic design, precision engineering, and superior motor technology. This holistic approach ensures maximum airflow per unit of energy consumed, directly impacting the bottom line of facilities reliant on robust cooling infrastructure. Aerodynamic optimization is the primary factor, where blade profile, pitch angle, and tip clearance are meticulously calculated to minimize air resistance and turbulence. This results in a smooth, high-volume flow characteristic of truly efficient high efficiency fans. Complementing this, the integration of high-performance, low-energy-consumption motors, such as EC motors, ensures that electrical input is converted into mechanical motion with minimal losses. This precision is vital whether the fan is used in general ventilation or critical condenser production applications. Efficiency is intrinsically linked to durability; a fan that degrades quickly cannot maintain its performance. A durable fan design utilizes corrosion-resistant materials and robust bearings to ensure consistent operation over a long lifespan, even in harsh environments like food sector cooling or energy facility ventilation. For applications with unique spatial or performance constraints, the availability of custom axial fans allows for a perfect match between the fan's capabilities and the system's specific requirements, eliminating efficiency losses from a poorly fitted standard unit. Ultimately, investing in a high-efficiency axial fan from a manufacturer like Günay Soğutma, who combines modern technology with disciplined production, translates into tangible long-term benefits. The initial investment is quickly offset by significantly lower energy bills, reduced maintenance frequency, and extended service life. By prioritizing these engineered components, you fortify your entire cooling system, achieving the reliability and cost-effectiveness essential for competitive industrial operations. How Do Axial Fans Improve Cooling Infrastructure Performance A robust cooling infrastructure is the lifeblood of industrial operations, and the axial fan serves as its cardiovascular system, directly dictating overall efficiency and reliability. By moving large volumes of air with precision, axial fans enhance heat exchanger performance, stabilize system pressures, and ensure consistent thermal management. This fundamental role makes the selection of high efficiency fans a strategic decision for any facility manager focused on optimizing industrial cooling performance. The performance improvement begins with enhanced heat transfer. In condenser production applications, axial fans force ambient air across condenser coils, drastically improving the rate of heat rejection and allowing the refrigeration system to operate at lower head pressures. This not only boosts cooling capacity but also reduces compressor load, leading to significant energy savings. For specialized environments like food sector cooling or demanding energy facility ventilation, a durable fan design ensures this high-level performance is maintained under corrosive or high-humidity conditions. Strategic integration is key to unlocking these benefits. Standard fans may not address unique spatial constraints or specific airflow patterns. This is where the option for custom axial fans proves invaluable, allowing engineers to tailor fan size, blade pitch, and motor specifications to the exact requirements of the cooling system. This precise matching eliminates performance gaps and inefficiencies that plague generic solutions, resulting in a more responsive and stable thermal management environment. Ultimately, upgrading your cooling infrastructure with high-performance axial fans from a disciplined manufacturer like Günay Soğutma delivers a cascade of operational advantages. The immediate result is a more efficient system with lower energy consumption. The long-term payoff is a durable fan design that minimizes unplanned downtime, extends the lifespan of associated equipment, and provides the reliability necessary for uninterrupted production. This strategic investment transforms your cooling system from a utility into a competitive asset. What Are The Benefits Of High-Quality Axial Fans Investing in high-quality axial fans is a strategic decision that yields significant operational and financial advantages for any facility reliant on industrial cooling. Far beyond simply moving air, a superior axial fan delivers measurable improvements in energy efficiency, system reliability, and total cost of ownership. These engineered components are pivotal in transforming a basic cooling setup into a high-performance, resilient cooling infrastructure. The most immediate benefit is a substantial reduction in energy consumption. High efficiency fans are designed with optimized aerodynamics and advanced motors that require less electricity to deliver the required airflow, directly lowering utility costs. This efficiency is critical in applications like condenser production and large-scale ventilation systems where fans operate continuously. Furthermore, a durable fan design, built with robust materials and precision bearings, ensures longevity and resistance to wear, dramatically reducing the frequency and cost of maintenance interventions. For specialized applications, the ability to procure custom axial fans unlocks targeted benefits. In food sector cooling, fans can be manufactured with hygienic coatings and sealed motors to meet strict sanitation standards, protecting product integrity. For challenging environments like energy facility ventilation, customized corrosion-resistant builds ensure dependable performance despite exposure to harsh elements. This tailored approach prevents the performance compromises often associated with standard, off-the-shelf solutions. The cumulative effect of these benefits is a cooling system that operates more reliably and cost-effectively over its entire lifecycle. By partnering with a manufacturer like Günay Soğutma, you are not just purchasing a component but investing in a solution engineered for sustained performance. The result is a significant enhancement in operational uptime, extended equipment service life, and a stronger bottom line, proving that superior quality in axial fan production is a cornerstone of modern industrial efficiency. Where To Use Axial Fans In Energy Sector Applications In the energy sector, managing thermal loads is critical for the safety, efficiency, and continuous operation of power generation and distribution assets. The axial fan is a fundamental component in this mission, providing the robust energy facility ventilation and cooling necessary to prevent overheating and maintain optimal performance. Its application is vital across a spectrum of facilities, from traditional power plants to renewable energy installations, forming a cornerstone of reliable industrial cooling infrastructure. One of the most critical uses for axial fans is in cooling the condensers of large-scale refrigeration and power cycle systems. Effective heat rejection in condenser production applications directly impacts the thermodynamic efficiency of the entire plant. These fans must be high efficiency fans to minimize the parasitic power load they impose, thereby maximizing the net energy output. Furthermore, they are deployed in turbine hall ventilation, control room air conditioning, and transformer cooling, where consistent airflow is non-negotiable for operational safety and equipment longevity. The harsh operating environments in the energy sector demand a particularly durable fan design. Fans may be exposed to extreme temperatures, humidity, and corrosive atmospheres, necessitating materials and coatings that standard units lack. This is where the capability for custom axial fans becomes essential, allowing for designs tailored to withstand specific site conditions, a requirement that differs significantly from standard food sector cooling applications. Selecting the right axial fan technology for energy sector applications is an investment in facility resilience and operational economics. A fan engineered for high efficiency and extreme durability reduces energy consumption and virtually eliminates unexpected downtime. Partnering with a manufacturer like Günay Soğutma ensures that your cooling components are built to the highest standards, delivering the long-term reliability and performance that the demanding energy sector requires for uninterrupted power generation and distribution. How To Ensure Long-Lasting Axial Fan Durability Achieving long-lasting durable fan design for axial fan components is a deliberate engineering process that directly impacts the reliability and cost-effectiveness of your industrial cooling system. Durability is not an afterthought but a fundamental design principle that ensures continuous operation, minimizes unscheduled downtime, and protects your investment against premature failure. This focus on longevity is especially critical in demanding energy facility ventilation and food sector cooling applications. The foundation of durability begins with material selection and construction quality. For high efficiency fans to withstand harsh environments, blades and housings must be crafted from corrosion-resistant alloys or composites, while shafts and bearings must be rated for heavy-duty, continuous operation. This robust construction prevents degradation from moisture, chemical exposure, and mechanical stress, which is vital for components used in critical processes like condenser production cooling. Equally important is the precision of the manufacturing process itself. A fan assembly must be perfectly balanced to eliminate vibration, a primary cause of bearing wear and structural fatigue. For unique applications, opting for custom axial fans allows for a design that is inherently suited to the specific operational stresses of the application, rather than forcing a standard unit to perform in conditions it was not engineered for. This tailored approach is a proactive strategy for maximizing service life. Ultimately, ensuring the long-term durability of an axial fan hinges on partnering with a manufacturer that integrates modern technology with disciplined production standards. At Günay Soğutma, this philosophy guarantees that every fan delivers not just initial performance but sustained reliability. By investing in a truly durable axial fan, you secure a component that reduces lifetime maintenance costs, enhances system uptime, and delivers a superior return on investment through years of dependable service in your cooling infrastructure. What Are The Key Features Of Efficient Axial Fans Identifying the key features of an efficient axial fan is essential for selecting a component that will deliver optimal performance within your industrial cooling system. True efficiency is a product of integrated engineering, where aerodynamic design, motor technology, and build quality converge to minimize energy consumption while maximizing airflow. These features distinguish standard fans from genuine high efficiency fans that significantly impact operational costs. The aerodynamic profile of the blades is paramount. Advanced computational fluid dynamics are used to shape blades that minimize turbulence and drag, ensuring smooth, high-volume air movement with minimal power input. This precision engineering is critical for applications like condenser production cooling, where fan performance directly affects the entire refrigeration cycle. Complementing this, the integration of high-efficiency motors, such as EC technology, ensures that electrical energy is converted into rotational force with minimal losses, a cornerstone of modern energy facility ventilation. A durable fan design is inseparable from long-term efficiency. Components constructed from corrosion-resistant materials and equipped with premium bearings maintain their performance characteristics over time, resisting the wear that degrades lesser units. For specialized environments in the food sector cooling industry, the option for custom axial fans allows for features like hygienic coatings and sealed motors, ensuring that efficiency is not compromised by the need for compliance or harsh conditions. Ultimately, these key features work in synergy to create a component that delivers sustained value. By choosing an axial fan engineered with these principles, you invest in a solution that reduces energy bills, extends equipment lifespan, and minimizes maintenance interruptions. Partnering with a manufacturer like Günay Soğutma guarantees access to these high-performance features, ensuring your cooling infrastructure is built on a foundation of proven efficiency and reliability. How Can Axial Fans Reduce Your Energy Consumption In an era of rising energy costs, optimizing industrial cooling systems for efficiency is a top priority for facility managers. The axial fan is a critical leverage point in this effort, offering a direct pathway to substantial energy savings through advanced engineering and intelligent design. Upgrading to modern, high efficiency fans can dramatically reduce the electrical load of your cooling infrastructure without sacrificing performance, delivering a rapid return on investment. The primary mechanism for energy reduction is superior aerodynamic efficiency. High efficiency fans are designed with precision-crafted blades that move air with minimal resistance, requiring less motor power to achieve the required airflow. This is particularly impactful in constant-duty applications like condenser production cooling and energy facility ventilation, where even a small percentage gain in efficiency translates into significant annual cost savings. Furthermore, many modern fans incorporate Electronically Commutated (EC) motors, which adjust speed based on demand, eliminating the energy waste of fixed-speed units. Durability also plays a crucial role in sustained energy savings. A durable fan design maintains its aerodynamic integrity over time, preventing the gradual efficiency loss that occurs as lesser fans wear down. For specialized applications in food sector cooling, where hygiene requirements are strict, opting for custom axial fans ensures the unit is perfectly matched to the environment, avoiding the performance penalties of an ill-fitting standard model. Ultimately, reducing energy consumption with axial fans is an investment in both operational efficiency and long-term financial performance. By selecting fans engineered for peak performance from a manufacturer like Günay Soğutma, you secure a component that continuously lowers your utility expenses. This strategic upgrade not only cuts immediate costs but also contributes to a more sustainable and reliable production environment, strengthening your entire cooling infrastructure for years to come.

Read More

What Are Shock Evaporators? Where Are They Used?

What Are Shock Evaporators And Their Applications In demanding industrial environments, maintaining precise temperature control is non-negotiable for process integrity and product quality. Standard cooling solutions often struggle with rapid heat load changes, leading to efficiency losses and potential system strain. Shock Evaporators represent a specialized component engineered to handle these intense, fluctuating demands, offering a pathway to significant energy savings and operational stability within Industrial Cooling Systems. A Durable Evaporator Design is paramount for shock applications, where thermal stress and pressure variations are extreme. These units are constructed with high-grade materials and precision engineering to facilitate rapid heat absorption, ensuring instantaneous response to sudden temperature spikes. This core functionality prevents equipment from overheating, directly contributing to extended machinery life and reduced unplanned maintenance downtime, reinforcing the reliability of the entire production line. The versatility of shock evaporators is showcased in sector-specific applications. In Food Industry Cooling, they are critical for rapid blast chilling and freezing processes, locking in freshness and complying with strict safety standards. Similarly, for Energy Sector Cooling Solutions, these components manage heat loads in power generation and industrial processing, ensuring continuous operation and protecting valuable assets. This adaptability highlights the need for Custom Evaporator Production to meet unique operational parameters. At Günay Sogutma, we leverage decades of manufacturing discipline to produce shock evaporators that are not just components but integral pillars of your cooling infrastructure. Our process combines advanced thermal modeling with rigorous quality control, resulting in units that deliver unparalleled high efficiency and long-term performance. We offer both serial and custom production capabilities, ensuring a perfect fit for any industrial requirement. Investing in a purpose-built shock evaporator system from a proven manufacturer translates directly to lower operational costs and enhanced facility uptime. By optimizing thermal management with a focus on Durable Evaporator Design, businesses achieve a stronger, more resilient cooling infrastructure capable of supporting production goals for years to come. This strategic approach to cooling is essential for any operation prioritizing sustainability and bottom-line results. How Do Shock Evaporators Work In Cooling Systems Understanding the operational principles of Shock Evaporators is key to optimizing Industrial Cooling Systems for peak efficiency. Unlike standard evaporators, shock models are engineered for rapid heat absorption to counteract sudden, intense thermal loads. This immediate response is critical in production environments where temperature stability directly impacts product quality and process continuity, preventing energy waste and system overload. The core function hinges on a high surface area design and optimized refrigerant flow, enabling the rapid phase change from liquid to vapor that defines the evaporation process. This rapid heat transfer is what allows these units to "shock" cool a process or product swiftly. A Durable Evaporator Design, resistant to thermal fatigue and corrosion, is essential to withstand the repetitive stress of these rapid cycles, ensuring longevity and minimizing maintenance interventions. Integrating these components effectively often requires Custom Evaporator Production to match specific operational parameters. For instance, in Food Industry Cooling, a shock evaporator might be tailored for a blast freezer to rapidly crust-freeze products, preserving texture and safety. In contrast, an application for Energy Sector Cooling Solutions might focus on managing heat from a turbine or reactor, requiring different materials and configurations for maximum reliability. Günay Sogutma approaches the manufacturing of these critical components with a discipline that prioritizes precision and performance. Our production process integrates advanced simulation tools to optimize internal geometries for maximum heat exchange before fabrication begins. This meticulous approach ensures every evaporator delivers on its promise of high efficiency and operational resilience, whether from our standard series or engineered as a custom solution. The strategic implementation of a correctly specified shock evaporator directly translates to tangible operational benefits. Facilities achieve higher cooling efficiency, which reduces energy consumption and associated costs. More importantly, by preventing temperature excursions, these components protect downstream equipment, extending its service life and ensuring uninterrupted production. Partnering with an experienced manufacturer like Günay Sogutma guarantees a solution that strengthens your entire cooling infrastructure for sustainable, long-term performance. Where Are Shock Evaporators Used Industrially The industrial application of Shock Evaporators is defined by their ability to manage sudden, high-intensity thermal loads that standard cooling components cannot handle efficiently. These specialized units are deployed where rapid heat removal is critical to process integrity, product quality, and overall equipment protection. Their strategic integration into Industrial Cooling Systems directly combats inefficiency and prevents costly production stoppages. In the Food Industry Cooling sector, shock evaporators are indispensable for processes like blast chilling and freezing. They ensure that food products pass through the critical temperature zone quickly, preserving texture, nutritional value, and safety by minimizing microbial growth. This rapid cooling capability is a cornerstone of modern food processing, demanding a Durable Evaporator Design that can withstand frequent washdowns and stringent hygiene standards. For Energy Sector Cooling Solutions, these components play a vital role in managing heat generated by turbines, transformers, and industrial reactors. The sudden heat spikes common in power generation and heavy industrial processes require an evaporator that can react instantaneously to prevent overheating and ensure continuous, reliable operation. This often necessitates Custom Evaporator Production to meet unique pressure, temperature, and spatial constraints. Günay Sogutma provides robust solutions tailored to these demanding environments. Our manufacturing discipline ensures that every shock evaporator is built to deliver high efficiency and withstand the rigors of its specific application. Whether a facility requires a standard model from our serial production line or a fully customized unit, our focus on precision engineering guarantees optimal performance and long service life. The correct deployment of shock evaporators is a strategic investment in operational reliability and cost control. By ensuring rapid and efficient heat removal, these components minimize energy consumption, reduce mechanical stress on connected equipment, and enhance overall system longevity. Choosing a proven partner like Günay Sogutma ensures your cooling infrastructure is equipped with durable, high-performance components designed for sustainable, low-maintenance operation. Are Shock Evaporators Suitable For Food Processing Shock evaporators are not just suitable but essential for modern Food Industry Cooling applications where rapid temperature reduction is critical for safety and quality. The ability to quickly remove heat from products like cooked meats, baked goods, or prepared meals directly inhibits bacterial growth and preserves texture, aligning with the stringent requirements of food safety protocols. This makes them a cornerstone of efficient and reliable Industrial Cooling Systems in food production facilities. The effectiveness of Shock Evaporators in food processing hinges on their specialized design for rapid heat transfer. They enable processes such as blast chilling, where products must be cooled from cooking temperatures to safe storage levels in a minimal amount of time. A Durable Evaporator Design is paramount here, requiring materials and construction that resist corrosion from washdown chemicals and withstand the thermal stress of rapid cycling. Given the diversity of food products and processing lines, effective integration often demands Custom Evaporator Production. A unit designed for a high-capacity spiral freezer will differ significantly from one used in a compact plate freezing system. This customization ensures optimal performance, energy efficiency, and a perfect fit within the existing production infrastructure, maximizing the return on investment for the facility. At Günay Sogutma, we understand the unique demands of the food sector. Our manufacturing process combines hygienic design principles with robust engineering to produce evaporators that deliver consistent, high-performance cooling. Whether a facility requires a standard model or a fully customized solution, our disciplined approach guarantees a component that enhances operational reliability and contributes to superior Energy Sector Cooling Solutions principles of efficiency. Integrating a purpose-built shock evaporator from a trusted manufacturer like Günay Sogutma directly translates to long-term operational advantages. Facilities benefit from reduced energy consumption due to faster cycle times, extended equipment life through stable thermal management, and minimized risk of spoilage. This strategic investment strengthens the entire cooling infrastructure, ensuring consistent product quality and contributing to a more sustainable and profitable operation. How To Choose A High-Efficiency Shock Evaporator Selecting a high-efficiency Shock Evaporator is a critical decision that directly impacts the performance and cost-effectiveness of your Industrial Cooling Systems. The process begins with a precise assessment of your thermal load requirements, cycle times, and the specific characteristics of your application. An optimally chosen unit ensures maximum heat transfer efficiency, leading to significant energy savings and enhanced process control. A thorough evaluation of the Durable Evaporator Design is paramount. Key factors include the material compatibility with your process and environment, such as stainless steel for Food Industry Cooling applications requiring corrosion resistance. The internal geometry, fin density, and tube configuration must be engineered to facilitate rapid boiling and minimize pressure drop, which are hallmarks of a high-performance shock evaporator built for longevity. The choice often leads to the necessity of Custom Evaporator Production to achieve a perfect fit for unique operational demands. Off-the-shelf solutions may not suffice for specialized processes in sectors like Energy Sector Cooling Solutions, where space constraints or extreme temperature differentials are common. A custom-designed evaporator ensures that every aspect of the component is optimized for your specific cooling challenge. Partnering with an experienced manufacturer like Günay Sogutma provides access to both proven serial designs and extensive customization capabilities. Our engineering team analyzes your requirements to recommend the most efficient configuration, whether it involves a standard model or a tailored solution. This disciplined approach to manufacturing guarantees that the selected evaporator will deliver reliable performance under demanding conditions. Ultimately, investing the time to choose the right high-efficiency shock evaporator from a reputable source like Günay Sogutma pays long-term dividends. The correct selection minimizes operational costs through reduced energy consumption, extends the lifespan of the entire cooling system by preventing thermal strain, and ensures consistent, reliable production output. This strategic approach strengthens your facility's infrastructure and supports sustainable operations for years to come. What Industries Benefit Most From Shock Evaporators Industries characterized by rapid heat generation, stringent process control, and high-value outputs derive the most significant benefits from integrating Shock Evaporators into their Industrial Cooling Systems. These components are specifically engineered to handle sudden, intense thermal loads that standard evaporators cannot manage efficiently, making them indispensable for applications where temperature stability is directly tied to product integrity, safety, and operational continuity. The Food Industry Cooling sector is a primary beneficiary, relying on shock evaporators for critical processes like blast chilling and rapid freezing. By pulling heat from products with exceptional speed, these systems preserve food quality, extend shelf life, and ensure compliance with health regulations. The Durable Evaporator Design required for these applications must withstand aggressive cleaning cycles and corrosive environments, ensuring long-term reliability. Similarly, the energy sector leverages these components for robust Energy Sector Cooling Solutions. Power plants and heavy industrial facilities use shock evaporators to manage heat from turbines, transformers, and chemical processes. The ability to rapidly dissipate large thermal spikes protects critical infrastructure from damage and prevents costly unplanned downtime, highlighting the need for precise engineering that often leads to Custom Evaporator Production. At Günay Sogutma, we provide the manufacturing expertise necessary to serve these demanding industries effectively. Our disciplined production process ensures that every shock evaporator, whether from our serial catalog or custom-designed, meets the highest standards for efficiency and durability. We work closely with clients to understand their unique thermal challenges and deliver solutions that optimize their entire cooling infrastructure. The strategic deployment of shock evaporators from a proven partner like Günay Sogutma translates into measurable operational advantages across these key industries. Facilities achieve greater energy efficiency, experience fewer mechanical failures, and benefit from reduced maintenance requirements. This investment in high-performance cooling technology directly strengthens production resilience, safeguards valuable assets, and enhances the overall sustainability of industrial operations. How Does A Shock Evaporator Improve Energy Efficiency A Shock Evaporator fundamentally improves energy efficiency by optimizing the heat transfer process at the core of Industrial Cooling Systems. Its specialized design enables rapid and complete evaporation of the refrigerant, which maximizes the cooling effect per unit of energy consumed. This high-efficiency operation reduces the workload on the compressor, which is the most energy-intensive component, leading to significant and immediate reductions in electricity consumption. The key to this performance lies in the enhanced thermal dynamics of a Durable Evaporator Design. By featuring an optimized surface area and internal geometry, shock evaporators facilitate a more effective phase change from liquid to vapor. This efficient heat absorption allows the system to achieve the desired cooling effect faster, shortening cycle times in applications like Food Industry Cooling and reducing the overall runtime of the refrigeration unit. Maximizing these energy savings often requires Custom Evaporator Production to perfectly match the specific thermal load and operational profile of a facility. A unit tailored for a power plant's Energy Sector Cooling Solutions, for instance, will have a different efficiency curve than one designed for a food processing line. This precision engineering ensures the evaporator operates at its peak performance point, eliminating energy waste from an improperly sized component. Günay Sogutma integrates advanced thermal modeling into our manufacturing process to create shock evaporators that deliver superior energy efficiency. Our disciplined approach ensures that every coil and fin is engineered to extract the maximum amount of heat with minimal energy input. This commitment to high performance is embedded in both our standard serial products and our custom-designed solutions, providing clients with a direct path to lower operational costs. The energy efficiency gained from a correctly specified shock evaporator provides a compelling return on investment. Facilities benefit from reduced utility bills, a smaller carbon footprint, and less thermal stress on the entire cooling system, which extends equipment lifespan. By partnering with an expert like Günay Sogutma, industrial operators can achieve a more sustainable and cost-effective cooling infrastructure built for long-term reliability and performance. What Makes A Shock Evaporator Durable And Reliable The durability and reliability of a Shock Evaporator are foundational to the long-term performance of any Industrial Cooling Systems. These qualities stem from a deliberate Durable Evaporator Design that prioritizes material integrity and engineering precision to withstand the extreme thermal cycling and mechanical stress inherent in rapid cooling applications. A robustly constructed unit is the primary defense against unplanned downtime and costly repairs. Material selection is a critical factor in achieving this longevity. For demanding environments like Food Industry Cooling, evaporators are fabricated from corrosion-resistant stainless steel to endure frequent chemical washdowns. In contrast, units for heavy-duty Energy Sector Cooling Solutions may utilize specialized alloys to resist high pressures and temperatures. This meticulous attention to material compatibility ensures the core structure remains intact under continuous operation. The manufacturing process itself is equally vital. Precision welding, controlled brazing techniques, and rigorous pressure testing are non-negotiable steps that eliminate potential failure points. This level of quality control is essential for both standard and Custom Evaporator Production, ensuring every unit, regardless of its configuration, meets the same high standard for structural integrity and leak-free performance over its entire service life. At Günay Sogutma, our manufacturing discipline is the cornerstone of product reliability. We combine advanced fabrication technology with traditional quality assurance protocols to produce shock evaporators that are built to last. Every component is subjected to stringent tests that simulate real-world operating conditions, verifying its ability to perform reliably day after day in the most challenging industrial settings. Investing in a genuinely durable and reliable shock evaporator from a trusted manufacturer like Günay Sogutma delivers profound operational benefits. It minimizes maintenance interventions, reduces the risk of catastrophic system failure, and ensures consistent cooling performance. This translates directly to higher productivity, lower total cost of ownership, and a more resilient cooling infrastructure that supports your business objectives for years to come. Guide To Installing Shock Evaporators In Your Facility A successful installation of a Shock Evaporator is critical for unlocking its full potential within your Industrial Cooling Systems. The process begins long before physical mounting, with a comprehensive assessment of the existing infrastructure, thermal load calculations, and spatial constraints. Proper planning ensures the new component integrates seamlessly, delivering the promised energy efficiency and performance without disrupting production workflows. The physical installation phase demands precision, particularly in aligning refrigerant lines and ensuring secure, vibration-resistant mounting. For applications in Food Industry Cooling, this also includes ensuring all connections meet stringent hygiene standards to prevent contamination. Employing a Durable Evaporator Design from the outset simplifies this process, as units are engineered for straightforward integration and long-term stability under operational stress. Many complex installations benefit significantly from Custom Evaporator Production, where the unit is pre-engineered to fit specific spatial and performance requirements. This is especially valuable in retrofitting older systems or designing solutions for unique Energy Sector Cooling Solutions where space is limited. A custom-designed evaporator minimizes on-site modifications, reduces installation time, and ensures optimal performance from the moment the system is commissioned. Partnering with Günay Sogutma provides access to comprehensive support that extends beyond manufacturing. Our expertise includes providing detailed installation guidelines and technical specifications for both our serial and custom products. This support ensures that the Shock Evaporators we produce are installed correctly, guaranteeing they operate at peak efficiency and reliability from day one. A correctly installed shock evaporator is an investment that pays dividends through enhanced system performance and reduced lifetime costs. It ensures maximum heat transfer efficiency, which lowers energy consumption and operational expenses. Furthermore, a proper installation minimizes mechanical strain on the entire cooling infrastructure, extending its service life and ensuring the reliable, uninterrupted operation that facilities managed by Günay Sogutma partners are known for. How To Maintain A Shock Evaporator For Longevity Proactive maintenance is the cornerstone of maximizing the service life and efficiency of a Shock Evaporator within your Industrial Cooling Systems. A disciplined maintenance regimen ensures that the unit continues to operate at peak performance, preventing the gradual degradation that leads to energy waste and premature failure. This systematic approach protects your investment and sustains the operational reliability critical to continuous production. The foundation of effective maintenance is regular inspection and cleaning. For Food Industry Cooling applications, this involves scheduled clean-in-place (CIP) cycles to prevent biofilm buildup and maintain optimal heat transfer coefficients. In other industrial settings, visual inspections for corrosion, icing, or physical damage are essential. A Durable Evaporator Design, with accessible components and robust construction, inherently simplifies these routine tasks, reducing maintenance time and labor costs. Monitoring operational parameters like refrigerant superheat and pressure differentials provides early warning signs of potential issues. For complex systems, especially those involving Custom Evaporator Production for specialized Energy Sector Cooling Solutions, adherence to the manufacturer's specific maintenance protocol is vital. This proactive monitoring allows for corrective actions before minor issues escalate into major repairs or unplanned production halts. Selecting a shock evaporator from Günay Sogutma provides access to components engineered for ease of maintenance. Our manufacturing discipline prioritizes not just initial performance but long-term serviceability. We provide comprehensive maintenance documentation for all our products, ensuring your technical team has the precise information needed to preserve the unit's efficiency and structural integrity over its entire lifespan. Committing to a structured maintenance plan for your shock evaporator directly translates to lower total cost of ownership and enhanced system reliability. It sustains high energy efficiency, minimizes the risk of catastrophic failure, and extends the operational life of the entire cooling infrastructure. This disciplined approach, supported by the quality inherent in Günay Sogutma products, ensures your facility benefits from dependable, cost-effective cooling for years to come.

Read More

Key Differences Between Condensers and Evaporators

What Is The Main Difference Between Condenser And Evaporator For industrial facilities aiming to optimize their industrial cooling infrastructure, understanding the fundamental distinction between a condenser and an evaporator is the first step toward achieving significant gains in energy efficiency and operational reliability. These two core components play opposing yet complementary roles within the industrial refrigeration cycle, and their proper function is critical for maintaining consistent production line temperatures and minimizing costly downtime. In simple terms, the evaporator vs condenser difference lies in their heat exchange functions. The evaporator is the component where the refrigerant absorbs heat from the process or space being cooled, causing it to evaporate from a liquid to a gas. The condenser then rejects this absorbed heat to the outside environment, condensing the refrigerant back into a liquid. This distinct operational pressure and temperature profile for each necessitates specialized design and disciplined manufacturing to ensure peak performance. Understanding this core distinction directly informs the selection of durable cooling components tailored to specific sector demands. For instance, high-quality evaporator production for a food processing plant focuses on materials and designs that withstand frequent washdowns and maintain precise temperature control. Conversely, robust condenser production for an energy sector application prioritizes performance in high-ambient temperatures. Günay Soğutma addresses these diverse needs through both custom cooling solutions for unique challenges and serial production for standardized reliability. Ultimately, the correct specification and integration of these components are what transform a standard setup into a high-performance energy efficient cooling system. Precise engineering in both the evaporator and condenser leads to lower compressor loads, reduced energy consumption, and extended equipment life. By partnering with a manufacturer like Günay Soğutma, which combines modern technology with rigorous production discipline, industrial managers can secure a cooling infrastructure that delivers long-term durability, ease of maintenance, and a stronger bottom line through optimized thermal management. How Does An Evaporator Function Differently From A Condenser At the heart of every effective industrial cooling system lies a precise thermal exchange process, and the functional divergence between the evaporator and condenser is its operational core. Grasping this difference is crucial for facility managers seeking to enhance the energy efficiency and reliability of their production lines by selecting the right components for their specific application and environmental conditions. The evaporator functions as the system's heat absorber, a critical distinction in the evaporator vs condenser comparison. Within the evaporator, low-pressure liquid refrigerant absorbs thermal energy from the target area—such as a process fluid or a chilled space—causing the refrigerant to boil and change into a low-pressure vapor. This phase change efficiently removes heat, providing the desired cooling effect. In contrast, the condenser performs the opposite role: it rejects the absorbed heat to the external environment, condensing the high-pressure, high-temperature refrigerant vapor back into a liquid. This fundamental functional difference dictates unique design and material requirements for each component, which is why specialized evaporator production and condenser production are essential. For example, evaporators in a food processing facility must be designed for efficient heat transfer with specific materials that resist corrosion from moisture and cleaning agents. Günay Soğutma’s expertise in creating durable cooling components ensures each unit is engineered for its precise role within the industrial refrigeration cycle, whether through standardized serial production or tailored custom cooling solutions for unique operational challenges. Selecting high-performance, correctly sized evaporators and condensers is the key to building an energy efficient cooling system that delivers long-term value. When both components function optimally in their distinct roles, the entire system operates with reduced mechanical strain, leading to lower energy consumption, extended equipment lifespan, and minimal unplanned maintenance. Trusting a proven manufacturer like Günay Soğutma guarantees that your cooling infrastructure is built with the technical precision required for sustained performance and operational cost savings. Which Cooling System Component Is Right For My Operation Selecting the correct components for your industrial cooling system is a critical decision that directly impacts operational efficiency, energy costs, and production reliability. The core of this choice lies in accurately assessing your facility's specific thermal management needs and understanding how components like evaporators and condensers function within the complete industrial refrigeration cycle. The primary consideration in the evaporator vs condenser selection is each component's distinct role. If your operation requires removing heat from a specific process or space—such as cooling a production line or preserving food products—the evaporator is the key component that requires precise sizing and material specification. Conversely, the condenser's role is to expel that absorbed heat from the system, and its selection depends heavily on the ambient conditions and available heat rejection methods at your facility. Partnering with a manufacturer that excels in both evaporator production and condenser production ensures a perfectly balanced system. Günay Soğutma offers both serial and custom cooling solutions, allowing for the selection of durable cooling components precisely matched to your operational demands, whether you need corrosion-resistant units for the food sector or high-capacity systems for energy applications. Ultimately, the right components form the foundation of an energy efficient cooling system that drives long-term value. Correctly specified evaporators and condensers work in harmony to minimize compressor workload, reduce electricity consumption, and extend the service life of the entire cooling infrastructure. By leveraging Günay Soğutma's disciplined manufacturing and technical expertise, you can achieve optimal cooling performance that enhances productivity and delivers significant cost savings through reduced downtime and maintenance. How To Identify If You Need A Condenser Or An Evaporator Correctly identifying whether a new evaporator or condenser is required for your industrial cooling system is a diagnostic skill that prevents costly misdiagnoses and ensures optimal performance. The decision hinges on understanding the distinct symptoms of failure and the unique role each component plays within the industrial refrigeration cycle, a critical step toward maintaining an energy efficient cooling system. The fundamental evaporator vs condenser distinction guides the troubleshooting process. If your system is failing to achieve the desired cooling temperature despite the compressor running, the issue likely points to the evaporator, which is responsible for heat absorption. Conversely, if the system is experiencing high head pressure, tripping on high-pressure switches, or reduced cooling capacity, the condenser, tasked with heat rejection, is the primary suspect and may require replacement or upgrade. This precise identification ensures you invest in the correct high-performance components from a specialized manufacturer. Günay Soğutma’s expertise in both evaporator production and condenser production allows for the provision of durable cooling components that directly address the root cause of the failure. Whether through standard serial units or bespoke custom cooling solutions, the correct component will restore system integrity. Making the right identification and sourcing from a disciplined manufacturer translates directly into long-term operational savings. Installing a correctly specified evaporator or condenser resolves the immediate fault and enhances the entire system's efficiency, leading to lower energy consumption and extended equipment lifespan. Partnering with Günay Soğutma guarantees that your cooling infrastructure is restored with components built for durability and sustained performance, minimizing future downtime and maintenance costs. Which Is More Critical For Energy Efficiency In Cooling Achieving superior energy efficiency in any industrial cooling system is not about choosing one component over another, but about ensuring both the evaporator and condenser operate at peak performance within a harmonized industrial refrigeration cycle. A deficiency in either component forces the compressor to work harder, drastically increasing power consumption and undermining the entire system's efficiency. While both are essential, the condenser often has a more direct and measurable impact on energy usage under challenging conditions. An undersized, fouled, or poorly maintained condenser forces the system to operate at elevated pressures, which significantly increases the compressor's workload and energy draw. However, this should not overshadow the critical role of the evaporator; an inefficient evaporator fails to absorb heat effectively, leading to longer run times and reduced capacity, which also wastes energy. The true evaporator vs condenser dynamic for efficiency is one of interdependence. This underscores the importance of sourcing both components from a manufacturer dedicated to precision engineering. Günay Soğutma’s disciplined approach to evaporator production and condenser production ensures that every unit is optimized for maximum heat transfer. By providing durable cooling components through both serial and custom cooling solutions, we guarantee that each part contributes to a balanced and highly effective system. Ultimately, the most critical factor for an energy efficient cooling system is the synergistic performance of correctly specified and manufactured components. Investing in high-quality evaporators and condensers from a trusted partner like Günay Soğutma creates a foundation for sustained energy savings, reduced operational costs, and enhanced equipment longevity, making efficiency a built-in feature of your cooling infrastructure. Does My Industrial Chiller Use An Evaporator Or Condenser Virtually every industrial cooling chiller relies on both an evaporator and a condenser to function; they are the fundamental components that define the vapor-compression industrial refrigeration cycle. Understanding the presence and role of each component is essential for optimizing chiller performance, planning maintenance, and ensuring your system operates as an energy efficient cooling system. Within your industrial chiller, the evaporator is the component responsible for the actual cooling effect. It absorbs heat from your process water or glycol solution, causing the liquid refrigerant inside it to boil and evaporate. The condenser, typically located in the chiller's air- or water-cooled loop, then performs the critical task of rejecting that absorbed heat to the atmosphere, condensing the refrigerant back into a liquid to begin the cycle anew. This fundamental evaporator vs condenser partnership is what enables precise temperature control for your production line. The quality of these core components dictates the chiller's reliability and efficiency. Selecting a chiller equipped with high-performance units from a dedicated manufacturer like Günay Soğutma ensures superior performance. Our expertise in precision evaporator production and condenser production results in durable cooling components designed for long service life under demanding conditions. We offer both standard and custom cooling solutions to match the exact thermal load and environmental factors of your application. Recognizing that your chiller depends on both components reinforces the need for a holistic approach to maintenance and component specification. Investing in chillers built with optimally sized and engineered evaporators and condensers from a proven manufacturer like Günay Soğutma is a direct investment in operational uptime and energy savings. This strategic approach minimizes the risk of failure, reduces long-term operating costs, and strengthens your facility's cooling infrastructure with reliable, high-efficiency technology. How To Optimize Cooling Performance With The Right Component Optimizing the performance of your industrial cooling infrastructure begins with the precise selection and integration of its core components. Achieving an energy efficient cooling system is not accidental; it is the direct result of choosing evaporators and condensers that are perfectly matched to your specific thermal load, operational environment, and performance goals within the industrial refrigeration cycle. The foundation of optimization lies in understanding the distinct roles in the evaporator vs condenser relationship and ensuring both are correctly sized. An oversized evaporator can lead to poor humidity control and short cycling, while an undersized condenser causes high head pressure and excessive energy consumption. True optimization occurs when both components work in perfect harmony, allowing the compressor to operate at its most efficient point. This level of precision demands components from a manufacturer with proven expertise in both evaporator production and condenser production. Günay Soğutma provides durable cooling components engineered for optimal heat transfer and long-term reliability. Whether through standard serial units or tailored custom cooling solutions, our disciplined manufacturing process ensures every component contributes to peak system performance. By strategically selecting the right evaporator and condenser for your application, you directly enhance cooling capacity, reduce energy costs, and extend the operational life of the entire system. Partnering with an expert manufacturer like Günay Soğutma transforms component selection from a simple procurement task into a strategic investment. This approach builds a resilient cooling infrastructure capable of supporting uninterrupted production and delivering significant long-term savings through superior efficiency and durability. What Role Does Each Component Play In A Refrigeration Cycle The reliability of any industrial cooling system hinges on the seamless orchestration of its core components within a continuous industrial refrigeration cycle. Understanding the precise role of each component is fundamental to diagnosing issues, specifying replacements, and achieving a truly energy efficient cooling system that drives down operational costs. In this cycle, the evaporator acts as the system's heat absorber. Here, low-pressure liquid refrigerant enters and absorbs thermal energy from the target medium—be it process water, air, or a product—causing the refrigerant to boil and transform into a low-pressure vapor. The compressor then pressurizes this vapor, and it moves to the condenser. The condenser's critical role is heat rejection; it dissipates the absorbed heat to the surrounding air or water, causing the high-pressure vapor to condense back into a liquid, ready to repeat the cycle. This fundamental evaporator vs condenser distinction dictates their design and construction requirements. Günay Soğutma's expertise in specialized evaporator production and condenser production ensures each unit performs its role with maximum efficiency. We manufacture durable cooling components designed for the specific pressures and thermal duties they encounter, offering both serial and custom cooling solutions for exact application matching. When each component excels in its designated role, the entire system operates with optimal efficiency, reducing compressor strain and energy consumption. Specifying high-performance evaporators and condensers from a disciplined manufacturer like Günay Soğutma is a direct investment in system longevity and operational reliability. This strategic approach minimizes unexpected downtime and ensures your cooling infrastructure supports continuous production with minimal maintenance intervention. Which Design Factors Differ Between Evaporators And Condensers The divergent operational roles of evaporators and condensers within the industrial refrigeration cycle necessitate fundamentally different design philosophies. Selecting components with the correct design parameters is paramount for achieving a reliable and energy efficient cooling system that meets the demanding requirements of modern industrial cooling applications. The primary evaporator vs condenser design difference lies in their operating pressures and temperatures. Evaporators are designed for low-pressure, low-temperature operation, optimizing their internal geometry and fin density for maximum heat absorption from the process fluid. Condensers, conversely, are engineered to withstand high pressures and temperatures, with designs focused on efficient heat dissipation to the ambient environment, often utilizing different fin spacing and tube arrangements to manage the phase change from vapor to liquid. These divergent requirements are why specialized evaporator production and condenser production processes are critical. Günay Soğutma meticulously engineers each component with materials and constructions suited to its specific thermal and mechanical stresses. Our disciplined manufacturing yields durable cooling components, whether through standardized serial options or fully engineered custom cooling solutions, ensuring optimal performance in corrosive food sector environments or high-ambient energy applications. Understanding and applying these distinct design factors is the key to building a high-performance cooling infrastructure. Components designed for their specific thermodynamic duty cycles operate more efficiently, reducing energy consumption and mechanical strain on the entire system. Partnering with a manufacturer like Günay Soğutma, which prioritizes design precision, guarantees that your investment translates into long-term operational reliability, reduced maintenance costs, and sustained cooling performance. How To Select The Best Condenser And Evaporator For Durability Selecting condensers and evaporators for maximum durability is a strategic decision that directly impacts the lifespan and reliability of your entire industrial cooling infrastructure. Long-lasting durable cooling components are not a matter of chance but the result of intentional design choices and disciplined manufacturing processes that ensure resilience under continuous operation. The selection process must begin with a thorough analysis of the operational environment and the specific demands placed on each component within the industrial refrigeration cycle. For an evaporator, this means evaluating factors like the corrosiveness of the process fluid, required temperature approach, and potential for frost formation. For a condenser, key considerations include ambient temperature extremes, exposure to contaminants, and the chosen heat rejection method. The distinct evaporator vs condenser functions dictate unique durability requirements. This critical evaluation underscores the value of partnering with a manufacturer that excels in both evaporator production and condenser production. Günay Soğutma integrates material science and robust engineering to create components built to endure. We offer both serial production for proven reliability and custom cooling solutions tailored to harsh conditions, such as using specific alloys for corrosive environments in the food sector or enhanced coatings for condensers in coastal energy plants. Choosing the most durable components ultimately builds a more energy efficient cooling system over its entire life cycle. Durable evaporators and condensers maintain their heat transfer efficiency for years, preventing the gradual performance degradation that increases energy costs. By selecting components from a trusted partner like Günay Soğutma, you secure a cooling system that minimizes unplanned downtime, reduces lifetime maintenance expenses, and delivers unwavering performance, protecting your production investment for the long term.

Read More

How to Select an Evaporator?