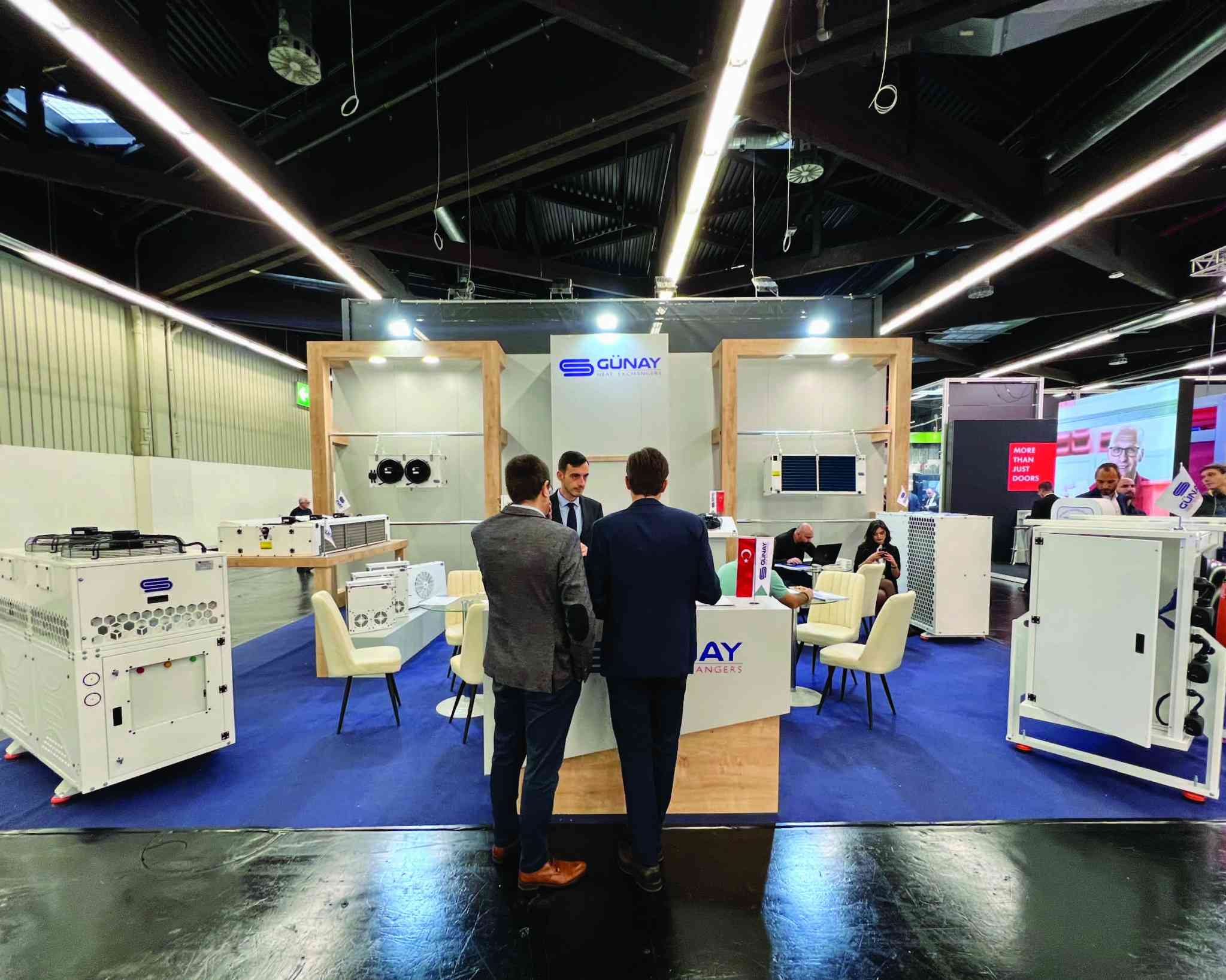

At Günay Heat Exchangers, we work to protect natural resources and build a sustainable future. We focus on using eco-friendly practices and maximizing energy efficiency to reduce our impact on the environment. We aim to meet future needs today and add value to society and the environment, ensuring a sustainable life for future generations

Your Global Solution Partner

We Offer Maximum Efficiency and Satisfaction to Our Customers with Our Services and Products at Global Standards.

40+ Years of Experience Leading Solutions in Cooling and Heating Sector

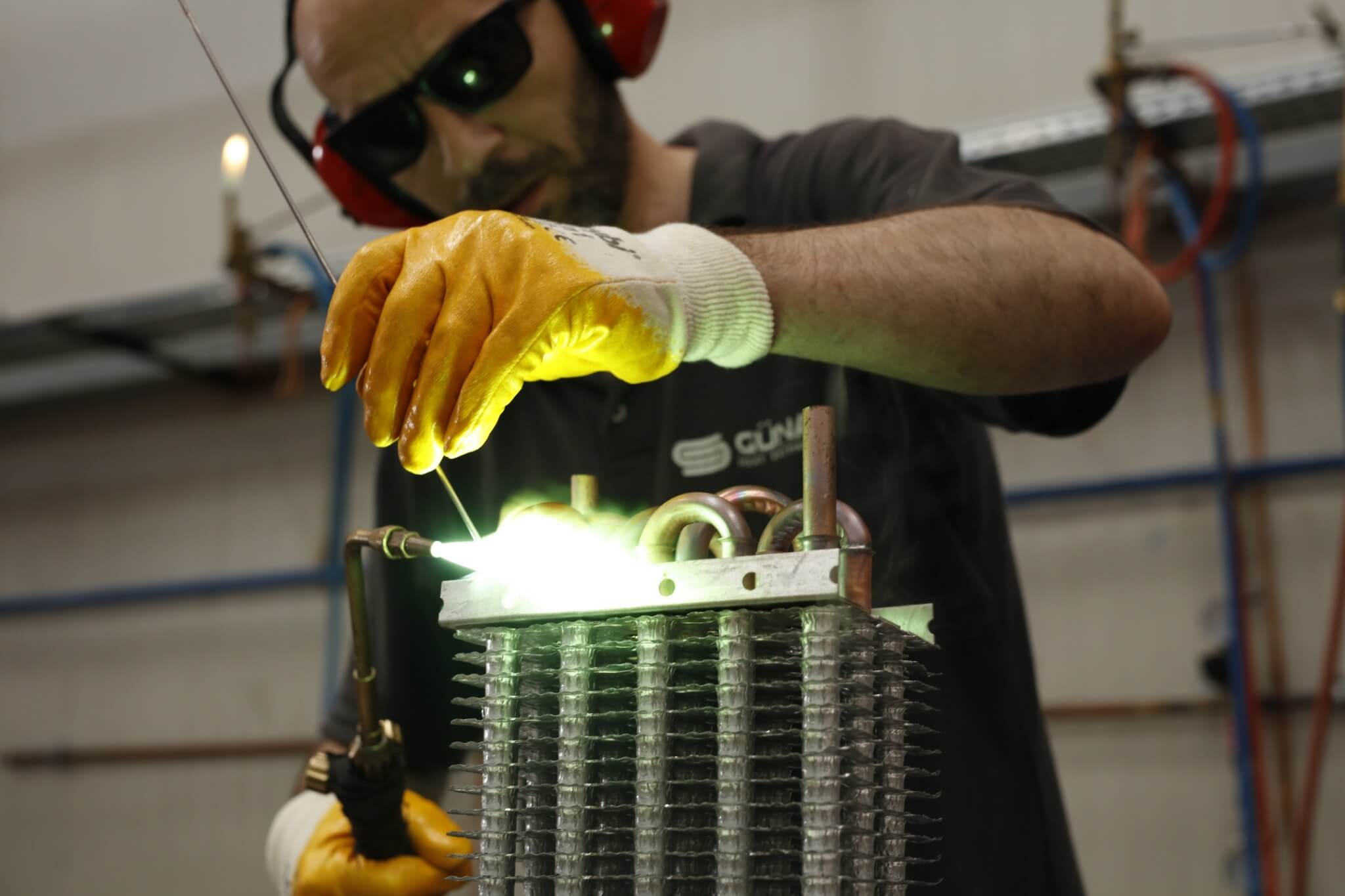

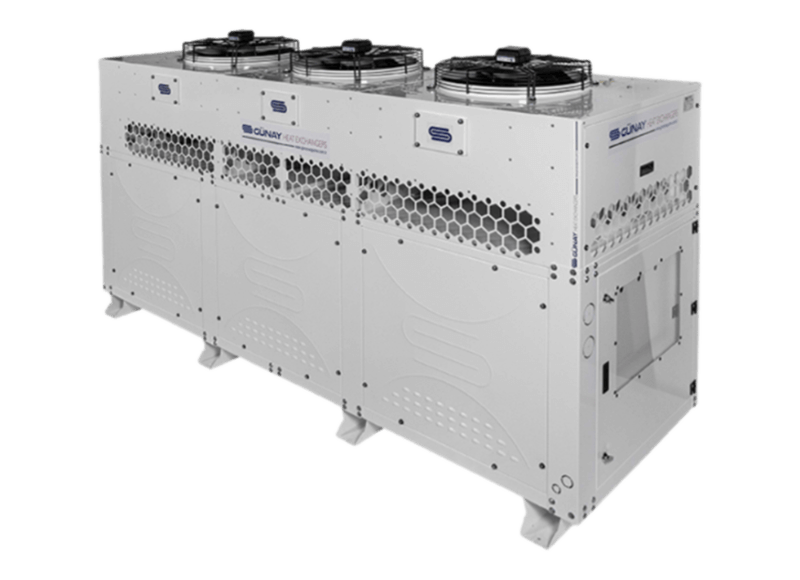

Since its establishment in 1986, our company has been serving with serial and special production evaporators, condensers and heat exchangers.

Your Power in the Sector: Gunay Cooling

Since 1986, we offer innovative and customized solutions with our high quality in Evaporators, Condensers and Heat Exchangers. We are working for you with our continuously developing infrastructure and customer-oriented approach.

Innovative Cooling Solutions Offering High Efficiency

Since its establishment in 1986, our company has been offering evaporators, condensers, and heat exchangers both in mass production and as custom-made. Embracing both traditional and modern service approaches, Günay Heat Exchangers continues to evolve by constantly updating its infrastructure in line with industry innovations and customer expectations.

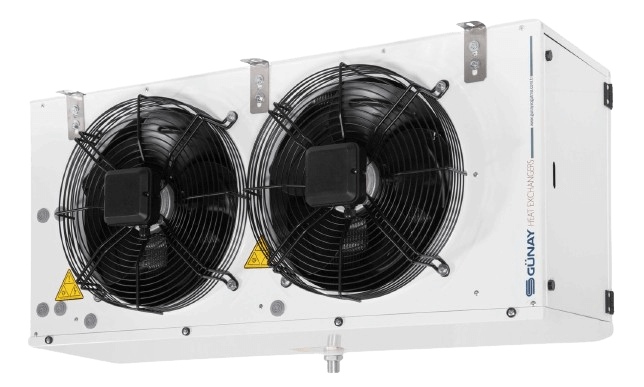

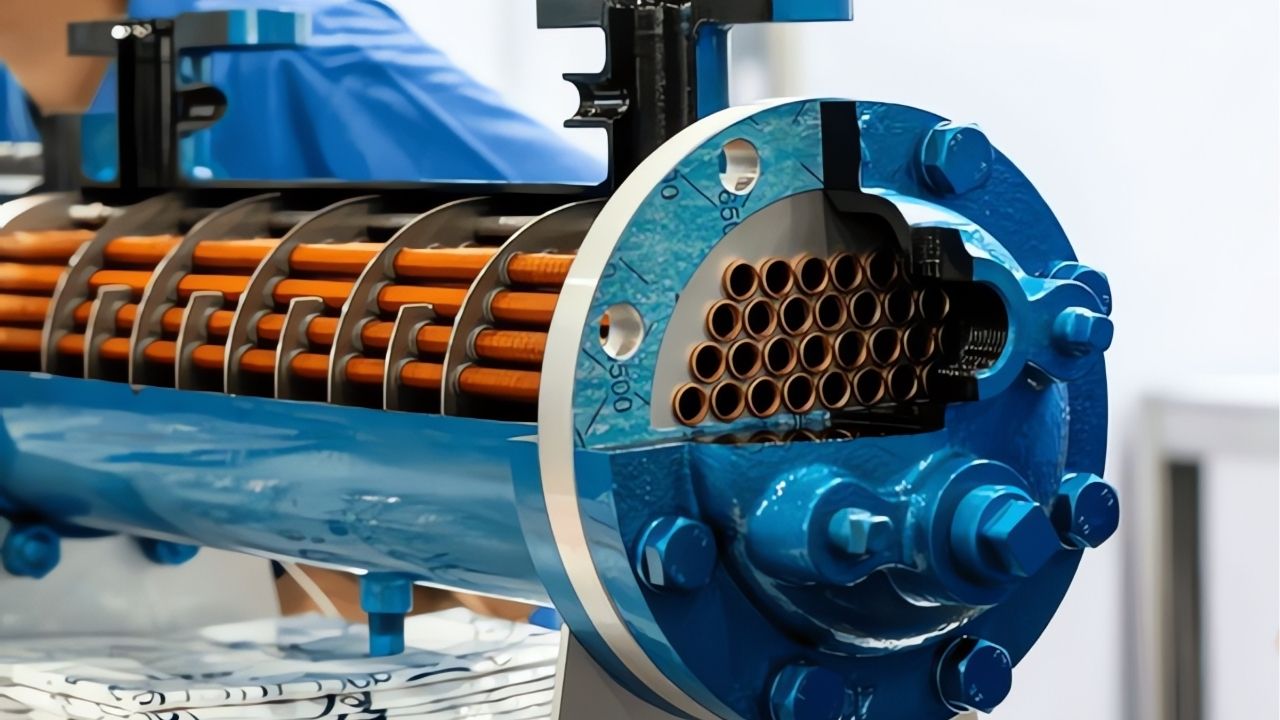

Evaporators

An evaporator is an essential component of cooling systems. Typically designed as a serpentine coil, it enables the refrigerant to evaporate and absorb heat from the surrounding environment. During this process, heat is transferred from the surroundings, thereby lowering the ambient temperature and achieving the desired cooling effect.

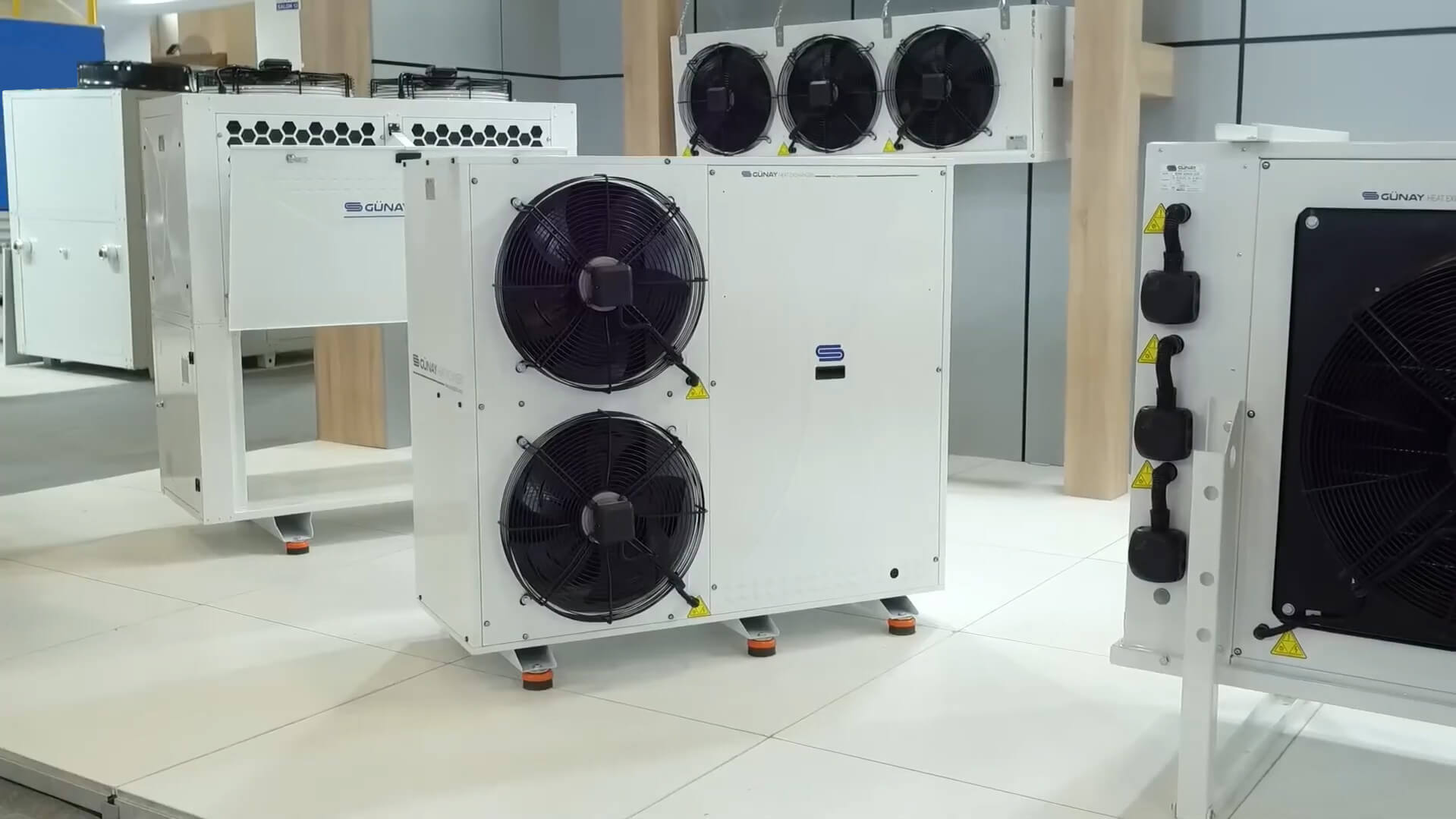

Condensers

The main function of a condenser is to condense the refrigerant gas into a liquid in the cooling cycle. During this process, the heat from the refrigerant gas is released to the surroundings, and the refrigerant condenses into a liquid form.

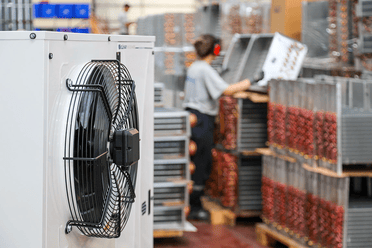

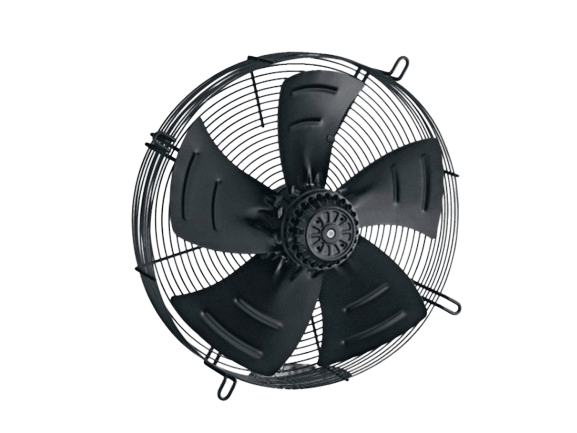

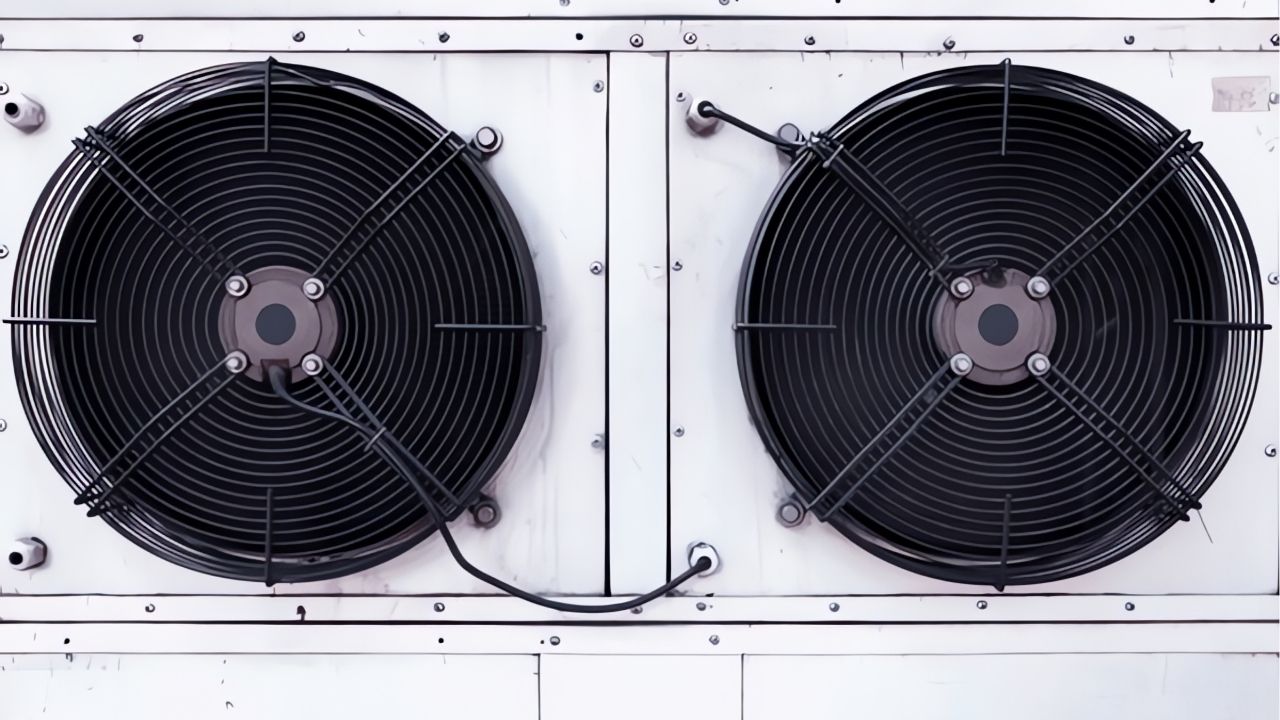

Axial Fans

Axial fans are designed to provide high airflow and play a critical role in industrial cooling solutions. These fans, which move air forward along the axis of the fan blades, are known for delivering high-volume airflow at low pressure. Thanks to these characteristics, they are an ideal solution for applications such as ventilating, cooling, or heating large areas.

Resistances

Defrost is the process of melting frost and ice that accumulate on the surfaces of air coolers. In cold storage rooms, industrial kitchen sections, and similar areas where defrosting is needed, heaters provide suitable solutions for various heating requirements with different size and power options.

We Are With You Every Step of the Way

Safe Choice

0

+

Export to Countries

0

%

Customer Satisfaction

0

+

Employees

Branches

Kocatepe Mahallesi Irmak Cad. No:43-45 Beyoğlu Dolapdere/İstanbul

Yassıören Mahallesi Akpınar Sanayi Bölgesi Fırat Sokak No:6/1 Hadımköy-Arnavutköy/İstanbul

Beşkonaklılar Mahallesi Kırçiçeği Caddesi No:13E Corner City Plaza Kepez/Antalya

Barbaros Burak Reis Caddesi No:112 D:A, 35090 Bornova/İzmir

Yassıören Mahallesi Belde Sokak No:17 Hadımköy-Arnavutköy/İstanbul

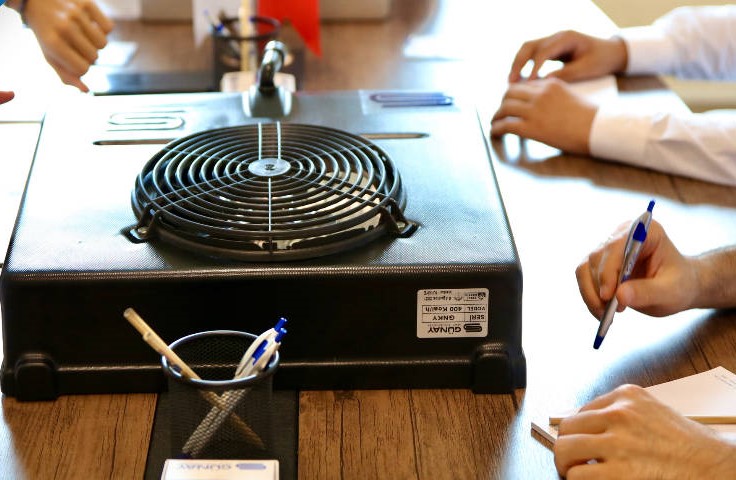

Education Workshop

Product Selection Program

Günay Heat Exchanger's Product Selection Program allows users to quickly and accurately select products such as evaporators, condensers, and heat exchangers. With its user-friendly interface and intelligent algorithm, it recommends the most suitable solutions for your industry and needs. As Günay Heat Exchanger, we are continuously enhancing the Product Selection Program to provide our customers with a superior experience and to simplify their work.

Blog

How To Extend Axial Fan Motor Life Through Proper Maintenance In demanding industrial settings, the operational lifespan of axial fan motors directly impacts cooling system reliability and energy consumption. Effective axial fan maintenance service is not merely a reactive task but a strategic imperative for achieving energy efficient fan motors and minimizing unexpected failures. Proper protocols extend beyond simple cleaning to encompass precise bearing care and electrical system diagnostics, ensuring maximum airflow with minimal power draw. This systematic approach is fundamental to reducing operational costs and enhancing overall cooling infrastructure resilience in food processing plants and energy generation facilities. A cornerstone of prolonging motor life is a rigorous preventive maintenance axial fan schedule focused on the heart of the system: the bearings and windings. Timely industrial bearing repair or replacement prevents friction-induced heat buildup, a primary cause of motor degradation. Specialized motor service for cooling systems involves checking insulation resistance, verifying alignment, and balancing the rotor to eliminate vibrations that accelerate wear. Companies like Günay Soğutma integrate this disciplined maintenance philosophy directly into their custom axial fan production, designing units for easier access and serviceability. The tangible benefits of this meticulous care are profound, most notably an extended fan lifespan that delays capital expenditure. More critically, it is the most effective strategy to reduce cooling system downtime, which can halt entire production lines in sectors where temperature control is non-negotiable. A well-maintained axial fan operates smoothly, consuming less energy and subjecting the motor to less stress, thereby delivering consistent cooling performance. This reliability is crucial for preserving product quality in the food sector and ensuring continuous operation in energy applications. Ultimately, investing in professional maintenance is an investment in long-term operational stability and efficiency. Partnering with an expert manufacturer ensures that service protocols are tailored to the specific demands of your facility's cooling infrastructure. By adhering to a disciplined maintenance regimen supported by high-quality components, businesses secure a significant return through lower energy bills, fewer emergency repairs, and uninterrupted production. This proactive approach transforms the axial fan from a potential point of failure into a pillar of dependable, sustainable cooling performance. What Is The Best Bearing Lubrication Schedule For Industrial Fans Determining the optimal bearing lubrication schedule is a critical component of any effective axial fan maintenance service, directly influencing system longevity and energy consumption. An ill-defined schedule leads to premature wear, increased friction, and higher power demands from energy efficient fan motors, undermining the core benefits of a modern cooling infrastructure. The ideal interval is not a universal standard but a calculated balance between operational hours, environmental conditions, and bearing type. For industrial facilities, a disciplined approach to lubrication is the first line of defense in a comprehensive preventive maintenance axial fan strategy. The foundation of a reliable schedule begins with the manufacturer's specifications, which for a provider like Günay Soğutma, are derived from rigorous testing in both custom axial fan production and serial models. High-temperature environments, such as those near condensers in energy sector applications, often necessitate more frequent greasing intervals than clean, climate-controlled food processing halls. Utilizing the correct lubricant grade and volume is equally vital; over-lubrication can cause overheating and seal damage, while under-lubrication accelerates metal-on-metal contact. This precise calibration prevents the need for costly industrial bearing repair and extends maintenance cycles. Adhering to a scientifically-backed lubrication plan yields significant operational advantages, most notably a proven extended fan lifespan for critical cooling components. Properly lubricated bearings run cooler and smoother, which reduces the mechanical stress on the entire assembly and supports the performance of integrated motor service for cooling systems. This proactive care is instrumental in efforts to reduce cooling system downtime, as scheduled lubrication is a quick, non-intrusive task compared to emergency bearing replacement during a production run. Ultimately, the best lubrication schedule is one that is diligently documented, consistently executed, and tailored to the specific operational profile of your industrial fans. Partnering with an experienced manufacturer ensures that maintenance protocols are optimized for your equipment's design and duty cycle. This disciplined focus on preventive care translates directly into lower total cost of ownership, safeguarding your cooling infrastructure's performance and ensuring uninterrupted production through superior reliability. How To Reduce Axial Fan Motor Energy Consumption With Maintenance For industrial facilities, the energy consumed by axial fan motors represents a significant and often reducible portion of operational expenses. Strategic maintenance is the most direct method to transform these components into truly energy efficient fan motors, moving beyond initial design to sustained operational excellence. A disciplined axial fan maintenance service protocol directly targets the mechanical and electrical inefficiencies that cause power waste. By focusing on key areas like bearing friction and aerodynamic cleanliness, businesses can achieve substantial energy savings while simultaneously enhancing system reliability and achieving an extended fan lifespan. The primary maintenance lever for reducing energy consumption is a rigorous preventive maintenance axial fan regimen that ensures optimal mechanical alignment. Proper industrial bearing repair and lubrication minimize rotational resistance, a major source of unnecessary motor load. Furthermore, comprehensive motor service for cooling systems includes verifying electrical connections and checking for phase imbalances, which can cause motors to draw excess current. Manufacturers like Günay Soğutma design fans for maintainability, whether through custom axial fan production or serial models, ensuring that components critical to efficiency are easily accessible for service. Regular cleaning of fan blades and heat exchange surfaces is another critical, yet often overlooked, aspect of energy-focused maintenance. Dust and debris accumulation on blades alter their aerodynamics, forcing the motor to work harder to achieve the required airflow. This simple task, performed as part of a scheduled service, directly lowers the amp draw of the motor. This proactive approach is essential to reduce cooling system downtime, as it prevents the slow degradation that leads to overheating and eventual failure during critical production periods. Ultimately, viewing maintenance as an energy-saving strategy rather than just a reliability measure unlocks major cost reductions. A well-maintained axial fan operates with minimal electrical waste, which compounds into significant annual savings on utility bills. Partnering with a manufacturer that prioritizes efficiency in both design and service guidance ensures that your cooling infrastructure performs at its peak for years. This disciplined approach to upkeep guarantees not only lower operational costs but also a more sustainable and reliable production environment. What Are The Signs Of Axial Fan Bearing Failure In Cooling Systems Early detection of axial fan bearing failure is paramount for maintaining uninterrupted cooling operations and preventing costly secondary damage. Recognizing the initial warning signs allows facility managers to schedule proactive industrial bearing repair before a catastrophic breakdown occurs. These symptoms often manifest as audible cues, physical vibrations, and performance degradation that directly impact system efficiency. An attentive axial fan maintenance service program is designed to identify these indicators early, which is essential to reduce cooling system downtime and protect associated equipment. The most common early sign of bearing wear is an audible change, progressing from a subtle hum or whine to a distinct grinding or rumbling noise as damage worsens. Simultaneously, increased vibration transmitted through the fan housing and structure indicates imbalance and internal component failure. This mechanical stress forces the energy efficient fan motors to work harder, leading to elevated operating temperatures and higher energy consumption. A comprehensive motor service for cooling systems will include vibration analysis and thermal imaging to quantify these issues objectively, providing data-driven evidence for necessary maintenance. As failure progresses, operational performance noticeably declines, with reduced airflow becoming a critical indicator of a problem. Excessive bearing play can cause the fan shaft to wobble, misaligning the blades and diminishing their cooling capacity. This loss of efficiency can jeopardize temperature-sensitive processes in food storage or energy production. Implementing a strict preventive maintenance axial fan schedule, supported by the engineering discipline of manufacturers like Günay Soğutma, is the most effective strategy for catching these signs early. Their expertise in both custom axial fan production and service ensures that maintenance protocols are precisely aligned with the equipment's design. Ultimately, understanding and acting upon these failure signs is a direct investment in operational continuity and cost control. Prompt intervention not only prevents a minor issue from escalating into a full motor replacement but also secures the fan's extended fan lifespan. Partnering with a knowledgeable provider for regular inspections transforms reactive repairs into predictable, planned service events, ensuring your cooling infrastructure remains a model of reliability and efficiency. How To Prevent Costly Axial Fan Downtime With Proactive Service Unplanned axial fan failure can cripple production lines and compromise climate-controlled environments, making proactive service a strategic necessity rather than an optional expense. The core objective of a disciplined maintenance program is to systematically reduce cooling system downtime by identifying and rectifying potential issues long before they lead to a breakdown. This approach transforms maintenance from a cost center into a value-driven activity that safeguards productivity and ensures an extended fan lifespan. Investing in a professional axial fan maintenance service is the most effective insurance against the high costs of emergency repairs and lost production time. The foundation of proactive service is a scheduled preventive maintenance axial fan plan that includes regular inspections, vibration analysis, and thermal monitoring. These techniques can detect imbalances, misalignments, and early-stage bearing wear that are invisible during normal operation. Addressing these issues through planned industrial bearing repair or lubrication prevents the cascade of damage that leads to motor failure. For comprehensive coverage, this should be integrated with a thorough motor service for cooling systems to check electrical integrity and ensure energy efficient fan motors are not straining under mechanical duress. Partnering with an experienced manufacturer like Günay Soğutma enhances this proactive strategy, as their deep expertise informs both service protocols and original equipment design. Their capability in custom axial fan production means that maintenance plans can be specifically tailored to the unique operational demands and environmental conditions of your facility. This level of customization ensures that service intervals and procedures are optimized for maximum reliability, whether for a standard serial model or a bespoke solution for a critical application. Ultimately, the shift from reactive fixing to proactive care delivers a clear return on investment through uninterrupted operations and lower total cost of ownership. Scheduled maintenance can be planned for production off-peak hours, eliminating the disruptive impact of emergencies. This disciplined approach not only prevents costly downtime but also maintains peak cooling efficiency, protecting your product quality and operational continuity. By prioritizing preventive service, businesses secure a reliable cooling infrastructure that supports long-term growth and stability. What Maintenance Ensures Maximum Axial Fan Efficiency And Airflow Achieving maximum axial fan efficiency and optimal airflow is a direct result of meticulously planned and executed maintenance, not just initial design specifications. A comprehensive axial fan maintenance service targets the three primary areas of performance loss: aerodynamic profile, mechanical integrity, and electrical efficiency. This disciplined approach ensures that fans operate as energy efficient fan motors, delivering designed airflow with minimal power consumption. For facilities reliant on precise climate control, this level of performance is essential for product quality and operational cost management, forming the core of a robust preventive maintenance axial fan strategy. The most impactful maintenance task for sustaining airflow is the regular cleaning of fan blades, guards, and adjacent heat exchanger surfaces. Accumulated dust and debris alter blade aerodynamics, creating drag and turbulence that drastically reduce volumetric flow. Simultaneously, ensuring mechanical precision through proper industrial bearing repair and alignment prevents shaft wobble and vibration, which misdirects airflow and wastes energy. A full motor service for cooling systems complements this by verifying that electrical components are delivering power efficiently, without losses that reduce torque and rotational speed. Manufacturers like Günay Soğutma build serviceability into their custom axial fan production, ensuring critical components are accessible for these essential upkeep procedures. The benefits of this holistic maintenance regimen are measurable and significant. Sustained peak efficiency directly lowers electricity costs and contributes to an extended fan lifespan by reducing mechanical and thermal stress on components. Most importantly, consistent airflow is key to preventing overheating in industrial processes, which helps to reduce cooling system downtime caused by inadequate temperature control. This reliability is non-negotiable in sectors like food processing, where a drop in cooling performance can lead to spoilage and significant financial loss. Ultimately, maintaining maximum fan efficiency is a continuous process that yields a high return on investment through energy savings and production stability. Partnering with an expert provider ensures that maintenance protocols are scientifically grounded and tailored to your specific operational environment. This proactive commitment to upkeep guarantees that your cooling infrastructure remains a dependable, high-performance asset, protecting your bottom line and ensuring long-term operational excellence. How To Perform A Comprehensive Axial Fan Bearing Inspection A comprehensive axial fan bearing inspection is a critical diagnostic procedure within any professional axial fan maintenance service, designed to preempt failure and sustain performance. This systematic assessment goes beyond superficial checks to evaluate the mechanical heart of the fan, identifying wear that can degrade efficiency and lead to unexpected stoppages. Executing a thorough inspection is a cornerstone of a robust preventive maintenance axial fan program, directly contributing to an extended fan lifespan and helping to reduce cooling system downtime. The inspection process begins with a detailed auditory and tactile analysis while the fan is operating, listening for irregular noises like grinding or rumbling and feeling for abnormal vibrations. After securing the power source, a physical examination checks for axial and radial play in the bearing by manually moving the fan shaft, with any significant movement indicating advanced wear. The condition of the lubricant is also assessed for contamination or degradation, as clean, proper-grade grease is essential for minimizing friction in energy efficient fan motors. For precision, advanced techniques like vibration analysis and thermography provide quantitative data on bearing health, often integrated into a full motor service for cooling systems. Findings from this inspection directly inform the need for industrial bearing repair or replacement, allowing for planned intervention rather than emergency response. Manufacturers like Günay Soğutma design their fans, including those from custom axial fan production, with inspection access points to facilitate this process. This design discipline ensures that critical components can be easily monitored and serviced, aligning manufacturing excellence with long-term maintainability. Ultimately, a meticulous bearing inspection transforms maintenance from a reactive cost into a proactive investment in reliability. By accurately diagnosing bearing condition, facilities can schedule repairs during planned outages, avoiding the far greater expense of production halts and collateral damage. This disciplined approach to predictive care ensures that your axial fans continue to operate at peak efficiency, safeguarding your cooling infrastructure's performance and delivering sustained value over its entire operational life. What Are The Key Steps In A Professional Axial Fan Motor Service A professional axial fan motor service is a systematic process that ensures the electromechanical core of your cooling system operates with peak reliability and efficiency. This goes beyond simple part replacement, encompassing diagnostics, cleaning, and precision adjustments that are essential for true energy efficient fan motors. As a critical component of a comprehensive axial fan maintenance service, this procedure is fundamental to a preventive maintenance axial fan strategy aimed at maximizing uptime and performance. The service begins with a thorough safety lockout and visual inspection of the motor and its connections for signs of overheating, corrosion, or physical damage. Electrical testing follows, using a megohmmeter to measure insulation resistance and identify potential winding failures that could lead to a short circuit. This diagnostic phase is a proactive form of motor service for cooling systems that catches issues before they cause operational failure. The mechanical inspection is equally vital, often involving industrial bearing repair or replacement if excessive noise or play is detected, as bearing integrity directly affects motor load and longevity. Following inspection, key steps include cleaning windings and internal components to prevent overheating and checking the alignment between the motor and fan shaft. Misalignment creates vibrational forces that waste energy and accelerate wear on both components. For specialized applications, manufacturers like Günay Soğutma leverage their experience in custom axial fan production to provide service protocols tailored to specific motor designs and environmental challenges. This ensures that every maintenance action is precisely calibrated for the equipment in use. Executing these steps meticulously delivers significant operational benefits, most notably an extended fan lifespan and a proven ability to reduce cooling system downtime. A professionally serviced motor runs cooler, draws less current, and operates more smoothly, directly reducing energy costs and the risk of unexpected breakdowns. This disciplined approach to maintenance transforms the motor from a potential liability into a dependable asset, ensuring long-term cooling performance and operational continuity for your facility. How Does Regular Maintenance Improve Axial Fan Longevity Regular maintenance is the single most influential factor in achieving an extended fan lifespan for industrial axial fans, directly countering the wear and tear of continuous operation. A disciplined axial fan maintenance service systematically addresses the root causes of degradation, transforming a reactive replacement cycle into a proactive preservation strategy. This approach is integral to a comprehensive preventive maintenance axial fan program, which not only prolongs equipment life but also sustains peak performance to reduce cooling system downtime and operational costs. The mechanism by which maintenance extends longevity is multifaceted, primarily by preventing the accumulation of small issues that escalate into major failures. For instance, timely industrial bearing repair and proper lubrication eliminate friction-induced heat, which is a primary cause of bearing seizure and subsequent motor burnout. Similarly, a thorough motor service for cooling systems ensures electrical components like windings and connections remain clean and tight, preventing resistance buildup that leads to overheating and insulation breakdown. This careful upkeep allows energy efficient fan motors to operate within their optimal thermal and mechanical parameters, significantly reducing stress. The design philosophy of the equipment itself plays a crucial role, which is why partnering with a manufacturer like Günay Soğutma is advantageous. Their expertise in both standard and custom axial fan production ensures that fans are engineered for maintainability, with accessible components that facilitate regular service. This synergy between robust design and disciplined upkeep creates a virtuous cycle where each maintenance intervention reinforces the fan's inherent durability, delaying the need for capital replacement by years. Ultimately, the investment in regular maintenance yields a substantial return by maximizing the operational life of critical cooling assets. This practice minimizes the total cost of ownership by spreading the initial investment over a much longer service period and avoiding the high cost of emergency replacements. By committing to a scheduled maintenance regimen, businesses secure not just longer-lasting equipment but also the reliable, efficient cooling performance that is essential for uninterrupted production and long-term operational success. What Is The Ideal Axial Fan Maintenance Plan For Peak Performance The ideal axial fan maintenance plan is a structured, proactive regimen designed not just to prevent failure but to consistently optimize performance and efficiency. This comprehensive axial fan maintenance service framework is the cornerstone of a reliable cooling infrastructure, ensuring that fans operate as energy efficient fan motors throughout their service life. A true preventive maintenance axial fan strategy is data-driven and scheduled, moving beyond calendar-based tasks to condition-monitored interventions that precisely address actual wear and performance metrics. An optimal plan is tiered, beginning with frequent visual and auditory checks for unusual noises or vibrations, followed by quarterly inspections of blade cleanliness, belt tension, and structural integrity. Semiannually, a more in-depth service should include vibration analysis, thermal imaging of bearings and electrical connections, and lubrication based on runtime hours rather than arbitrary dates. This disciplined approach allows for timely industrial bearing repair before failure occurs. Annually, a comprehensive motor service for cooling systems should be performed, including electrical testing and alignment verification to ensure all components work in harmony. The specificity of the plan is crucial, which is why collaboration with an expert manufacturer like Günay Soğutma is invaluable. Their deep understanding from custom axial fan production enables them to tailor maintenance schedules to the exact operational environment, whether a fan is exposed to high humidity in a food plant or dust in an energy facility. This customization ensures that the maintenance intensity matches the application's demands, preventing both under-servicing and unnecessary downtime. Adhering to this ideal plan delivers measurable outcomes: a significant extended fan lifespan and a powerful strategy to reduce cooling system downtime. The result is a higher return on investment through sustained peak airflow, lower energy consumption, and the avoidance of catastrophic failures. By implementing a scientifically-backed maintenance plan, businesses transform their axial fans from consumable components into long-term, high-performance assets that reliably support production and profitability.

Read More

What Is Periodic Maintenance For Industrial Cooling Systems In demanding industrial environments, the performance of a cooling system is inseparable from overall operational efficiency. Unplanned downtime or gradual performance degradation in these systems leads to significant production halts and inflated energy costs. A meticulously planned periodic cooling system maintenance program is not an optional expense but a strategic investment that directly safeguards facility cooling efficiency and production continuity. This proactive approach transforms a potential vulnerability into a cornerstone of operational stability. A comprehensive preventive maintenance plan for industrial applications involves systematic inspections and servicing of critical components. This includes essential tasks for evaporator condenser maintenance, such as cleaning coils, checking refrigerant levels, and verifying the performance of axial fans and electrical resistances. For specialized sectors like the food sector cooling or energy sector cooling, these checks also ensure compliance with stringent hygiene and safety standards, protecting both product quality and equipment integrity. Collaborating with an experienced manufacturer like Günay Soğutma elevates maintenance from a routine task to a value-added service. Our deep expertise in the production of core components means our industrial cooling service teams possess unparalleled insight into system longevity and performance optimization. Whether supporting systems built from our serial production lines or complex custom cooling solutions, this manufacturer-level knowledge ensures maintenance actions are precise, effective, and tailored to the specific demands of your production lines. The ultimate goal of a disciplined maintenance regimen is the establishment of reliable cooling systems that deliver long-term value. Regular servicing prevents minor issues from escalating into catastrophic failures, drastically reducing emergency repair costs and unplanned interruptions. This proactive care maximizes the lifespan of equipment, ensuring that the high efficiency and durability designed into components like evaporators and condensers are fully realized over their entire operational life. By implementing a structured maintenance strategy with a trusted partner, industrial facilities can achieve a significant reduction in total cost of ownership. This commitment to proactive care translates directly into sustained energy savings, minimized operational risks, and uncompromising production reliability. Optimize your cooling infrastructure's performance and durability by integrating expert periodic maintenance into your core operational strategy for enduring efficiency and cost control. How Often Should My Cooling Equipment Be Serviced Determining the optimal service interval for your cooling equipment is a critical decision that directly impacts operational expenditure and system longevity. A generalized schedule is insufficient for the unique demands of industrial settings, where factors like continuous operation, environmental contaminants, and load variability dictate maintenance needs. Establishing a correct preventive maintenance plan is the first step toward achieving peak facility cooling efficiency and avoiding costly unplanned downtime. This tailored approach ensures your investment in reliable cooling systems delivers maximum return over its entire lifecycle. The frequency of periodic cooling system maintenance depends heavily on the specific components and their operating conditions. Core elements like evaporators and condensers in heavy-use environments may require checks every three to six months, focusing on evaporator condenser maintenance tasks such as coil cleaning and pressure verification. Systems engineered for durability, like those from Günay Soğutma, are designed to withstand rigorous cycles, but even high-performance components benefit from regular expert assessment to maintain energy efficiency. Sector-specific requirements further refine service schedules. For instance, food sector cooling applications often mandate more frequent inspections to adhere to strict hygiene protocols, preventing contamination and ensuring product safety. Similarly, the high-heat and continuous demands of energy sector cooling infrastructure necessitate a robust schedule to prevent failure in critical processes. An expert industrial cooling service provider can analyze your operational data to build a predictive, rather than just a preventive, timeline. Partnering with the original manufacturer for servicing, especially for custom cooling solutions, provides a significant advantage. Manufacturers possess intimate knowledge of the system's design tolerances and potential failure points, allowing for exceptionally precise maintenance intervals. This level of care ensures that the advanced engineering and disciplined manufacturing built into the equipment translates into real-world durability and sustained performance, minimizing disruptive interventions. Ultimately, the question of service frequency is answered by a commitment to proactive, data-driven care. A well-calibrated maintenance strategy is not a cost but a strategic tool for reducing long-term operational expenses. By aligning service intervals with actual usage and environmental factors, facilities can secure uninterrupted production, optimized energy consumption, and the full lifespan of their cooling assets, solidifying cooling reliability as a competitive advantage. Why Is Periodic Cooling Maintenance Critical For Efficiency Periodic cooling system maintenance is the fundamental discipline that bridges the gap between theoretical design efficiency and real-world operational performance. Even the most advanced cooling systems experience gradual performance decay due to factors like fouling, refrigerant drift, and mechanical wear, which silently degrade facility cooling efficiency. A proactive preventive maintenance plan directly counters this degradation, ensuring that energy consumption remains optimized and cooling capacity meets design specifications consistently. This critical link to efficiency is most evident in the performance of core components. For example, neglecting evaporator condenser maintenance allows dirt and scale to accumulate on coils, forcing compressors and fans to work harder to reject the same amount of heat. This results in a measurable increase in energy draw and a decrease in cooling output. Regular cleaning and inspection by a specialized industrial cooling service team restores heat transfer efficiency, directly lowering operational costs and protecting the system from strain. The necessity for this disciplined approach is amplified in critical sectors. In food sector cooling, efficiency is synonymous with both cost control and product safety, as temperature fluctuations can compromise quality. For energy sector cooling applications, where cooling failure can halt entire processes, maintained efficiency is non-negotiable for operational continuity. This makes disciplined maintenance a core component of operating reliable cooling systems in these demanding environments. Manufacturers like Günay Soğutma design systems for high efficiency, but this potential is only fully realized through proper upkeep. Our expertise in producing both serial and custom cooling solutions provides a deep understanding of how to maintain optimal performance under specific industrial loads. Servicing by the original manufacturer ensures that maintenance protocols align perfectly with the engineered tolerances of the equipment, preserving its designed-in efficiencies. Ultimately, viewing maintenance as a critical efficiency driver transforms it from a reactive cost into a strategic investment. The incremental cost of regular service is vastly outweighed by the long-term savings in energy bills, avoided emergency repairs, and extended equipment lifespan. By prioritizing systematic maintenance, facilities secure not just immediate performance but also the long-term durability and cost-effectiveness of their entire cooling infrastructure. What Does a Professional Cooling System Checkup Include A professional cooling system checkup is a comprehensive diagnostic and corrective procedure essential for sustaining operational integrity. This structured periodic cooling system maintenance goes beyond superficial inspections to deliver a detailed assessment of component health and system-wide facility cooling efficiency. It is the actionable core of any effective preventive maintenance plan, designed to identify potential failures before they disrupt production and escalate into costly repairs. This proactive approach is fundamental for maintaining reliable cooling systems in demanding industrial settings. The checklist for a thorough industrial cooling service is methodical and component-specific. A critical focus is evaporator condenser maintenance, which involves cleaning coils to restore optimal heat transfer, checking refrigerant levels and pressures, and verifying the operation of fans and pumps. Electrical systems are inspected for secure connections and proper amperage draw, while controls and safety devices are calibrated and tested to ensure they function as designed under load conditions. Each step is documented to track performance trends over time. For specialized applications, the checkup incorporates sector-specific protocols. In food sector cooling, inspections include verifying sanitary conditions and ensuring temperature recording systems are accurate for compliance. Checks for energy sector cooling systems often place greater emphasis on vibration analysis and the integrity of high-pressure components. This tailored approach ensures that custom cooling solutions receive maintenance that aligns precisely with their unique operational profiles and environmental stresses. When performed by the original manufacturer, such as Günay Soğutma, the checkup benefits from unparalleled system familiarity. Our technicians utilize specific knowledge of the design and manufacturing tolerances of each component, from serial-produced axial fans to bespoke evaporator designs. This insider perspective allows for more precise adjustments and recommendations, ensuring that the inherent durability and efficiency of the equipment are fully maintained throughout its service life. Ultimately, a professional checkup transforms reactive maintenance into a strategic asset. The detailed report provided after service offers a clear snapshot of system health and a roadmap for future interventions. Investing in these comprehensive evaluations is a direct investment in reduced energy consumption, extended equipment lifespan, and uninterrupted production, solidifying the cooling system as a pillar of long-term operational stability and cost control. How To Schedule Industrial Cooling Maintenance Services Establishing a systematic schedule for industrial cooling service is a strategic operational decision that directly influences production uptime and financial performance. Effective scheduling transforms periodic cooling system maintenance from an unpredictable interruption into a planned, efficient event that enhances facility cooling efficiency. The process begins with a thorough assessment of your operational calendar, production cycles, and seasonal demands to identify optimal windows for service that minimize impact on output. Proactively integrating these services into your annual plan is the foundation for operating reliable cooling systems. The scheduling frequency should be dictated by the specific components and their duty cycles. A robust preventive maintenance plan accounts for the different needs of evaporators, condensers, and fans, aligning service intervals with manufacturer recommendations and actual operating hours. For critical tasks like evaporator condenser maintenance, scheduling during periods of lower production demand ensures that cleaning and inspections can be performed thoroughly without rushing. Partnering with a provider like Günay Soğutma allows for scheduling that is informed by deep knowledge of component lifespans and failure modes. Sector-specific operational rhythms must also guide the schedule. The food sector cooling often requires more frequent, regimented maintenance aligned with production batches and hygiene audits. In contrast, the energy sector cooling may schedule major services during planned plant shutdowns to ensure continuous operation during peak demand periods. For facilities utilizing custom cooling solutions, the scheduling process should incorporate unique design specifications and access requirements provided by the original manufacturer. Advanced scheduling with a trusted service provider unlocks significant logistical advantages. It allows for the pre-ordering of specific parts, the assignment of specialized technicians, and the coordination of any necessary support services. This level of preparation ensures that maintenance is executed efficiently, reducing the service window and associated downtime. It also facilitates better budget forecasting, turning maintenance from a variable cost into a fixed, manageable operational expense. Ultimately, a well-orchestrated maintenance schedule is a powerful tool for cost management and risk mitigation. By planning service intervals strategically, facilities can avoid the high costs of emergency repairs and the operational chaos of unplanned downtime. This disciplined approach to scheduling is a direct investment in the long-term durability, energy efficiency, and unwavering reliability of your industrial cooling infrastructure, securing its performance for years to come. Can Regular Maintenance Reduce My Cooling Costs Regular periodic cooling system maintenance is one of the most effective strategies for reducing the total cost of ownership for industrial cooling assets. While often perceived as an expense, a disciplined preventive maintenance plan functions as a powerful financial lever that directly lowers energy consumption, prevents catastrophic failures, and extends equipment service life. The question is not if maintenance saves money, but how significantly it impacts operational budgets by sustaining peak facility cooling efficiency and ensuring reliable cooling systems. The most immediate cost reduction comes from optimized energy efficiency. A well-maintained system operates with minimal resistance. For instance, proactive evaporator condenser maintenance ensures clean coils and proper refrigerant charge, allowing compressors and fans to work at their designed capacity without overexertion. This directly translates into lower electricity bills, as even minor fouling can increase energy draw by 10 percent or more. Engaging a specialized industrial cooling service provider like Günay Soğutma ensures these efficiency gains are consistently realized. Substantial savings are also realized by avoiding emergency repair scenarios and production downtime. Unplanned failures in critical sectors like food sector cooling can lead to spoilage and compliance issues, while outages in energy sector cooling can halt entire operations. The cost of an emergency service call, expedited parts, and lost production far exceeds the planned cost of routine inspections. This is especially critical for custom cooling solutions, where replacement components may have longer lead times. Perhaps the most significant long-term cost reduction is the extension of the equipment's operational lifespan. Regular maintenance prevents the cumulative wear and tear that leads to major component failures. By addressing small issues promptly, the system avoids the strain that shortens the life of compressors, motors, and heat exchangers. This deferral of capital expenditure for system replacement is a major financial benefit, protecting your investment for years beyond its expected service life. Ultimately, the Return on Investment for regular maintenance is undeniable. It systematically reduces energy costs, eliminates unpredictable repair expenses, and maximizes the utility of your capital equipment. Viewing maintenance not as a cost but as a strategic investment in operational stability and cost control is the key to unlocking the full economic potential of your industrial cooling infrastructure. How Does Maintenance Extend Evaporator And Condenser Life Extending the operational lifespan of evaporators and condensers is a primary economic benefit of a disciplined maintenance strategy, directly protecting your capital investment. These core heat exchangers are subject to constant thermal stress and environmental contamination, which gradually degrade their performance and structural integrity. A systematic preventive maintenance plan directly counteracts these forces, ensuring that the high efficiency and durability designed into these components are preserved for their maximum possible service life. This proactive care is the cornerstone of reliable cooling systems. The mechanism of life extension is rooted in preventing cumulative damage. Specific evaporator condenser maintenance tasks, such as regular coil cleaning, prevent fouling that forces compressors to operate at higher pressures and temperatures. This reduced mechanical strain on the entire system prevents premature wear on tubes, fins, and compressor valves. Furthermore, checking and correcting refrigerant charge during periodic cooling system maintenance ensures the system operates within its designed parameters, avoiding conditions like liquid slugging or overheating that can cause immediate catastrophic failure. This approach is critical in harsh industrial environments. In food sector cooling, maintenance prevents corrosion from cleaning agents and organic buildup, while in energy sector cooling, it mitigates the effects of high ambient temperatures and particulate matter. For custom cooling solutions engineered for specific challenges, maintenance protocols from the original manufacturer like Günay Soğutma are tailored to protect those unique design features from degradation. Expert industrial cooling service goes beyond cleaning to include predictive elements. Technicians perform vibration analysis, eddy current testing, and leak detection to identify micro-fractures or material fatigue long before they lead to failure. This allows for planned, cost-effective component replacement during scheduled downtime, rather than an emergency shutdown. This level of foresight is essential for maintaining unwavering facility cooling efficiency and avoiding disruptive incidents. By investing in regular, expert maintenance, facilities effectively decelerate the aging process of their most critical cooling components. The incremental cost of service is negligible compared to the expense of replacing a major evaporator or condenser assembly and the associated production losses. This strategic focus on longevity ensures your cooling infrastructure delivers value far beyond its expected lifespan, maximizing return on investment and operational stability. What Are The Risks Of Skipping Cooling System Maintenance Neglecting periodic cooling system maintenance introduces a cascade of operational and financial risks that can severely impact production continuity and profitability. What may appear as short-term cost savings quickly transforms into exponential losses from equipment failure, energy waste, and unplanned downtime. Operating without a structured preventive maintenance plan means forfeiting control over facility cooling efficiency and relying on luck rather than engineering discipline to sustain operations. This approach directly undermines the foundation of reliable cooling systems. The most immediate risk is a steep decline in energy efficiency. Without routine evaporator condenser maintenance, fouling on heat exchanger surfaces forces compressors to work harder, increasing power consumption by 20 percent or more. This silent energy tax accumulates into a significant financial drain over time. Furthermore, minor issues like refrigerant leaks or electrical imbalances go undetected, progressing into major failures that require costly emergency industrial cooling service interventions and potentially catastrophic component damage. Sector-specific risks are particularly severe. In food sector cooling, skipped maintenance can lead to temperature excursions that spoil entire batches and violate health regulations, resulting in massive financial and reputational damage. For energy sector cooling infrastructure, a failure can trigger a chain reaction that halts critical processes, with downtime costs measured in millions per hour. The unique design complexities of custom cooling solutions from manufacturers like Günay Soğutma make them especially vulnerable to improper operation when maintenance is deferred. The long-term consequence is premature system obsolescence. Components subjected to continuous stress without corrective maintenance experience accelerated wear, shortening their functional lifespan by years. A compressor that should last a decade may fail in half that time, forcing a capital investment long before it is financially planned. This neglect also voids warranties and eliminates the performance data needed for predictive planning, leaving facility managers to operate reactively. Ultimately, the risks of skipping maintenance far outweigh the perceived savings. The strategy of deferred upkeep converts predictable, manageable expenses into unpredictable, catastrophic losses. Investing in regular professional maintenance is the only proven method to mitigate these risks, ensuring operational stability, protecting your capital investment, and securing the long-term performance of your industrial cooling infrastructure. How To Create A Preventive Maintenance Plan For Coolers Developing a robust preventive maintenance plan is a systematic process that transforms cooling system management from reactive to strategically proactive. This foundational document serves as a roadmap for sustaining peak performance, ensuring facility cooling efficiency, and preventing costly unplanned downtime. The creation process begins with a comprehensive audit of all cooling assets, documenting their model specifications, operational histories, and current performance benchmarks to establish a baseline for all future periodic cooling system maintenance activities. This meticulous approach is essential for building reliable cooling systems. The core of the plan involves defining task-specific schedules for each major component. Critical activities like evaporator condenser maintenance must be scheduled based on operating hours and environmental conditions, with clear procedures for coil cleaning, leak detection, and pressure testing. The plan should integrate manufacturer recommendations, especially for specialized equipment from providers like Günay Soğutma, whose expertise ensures that maintenance intervals align perfectly with the designed durability of each component. Partnering with a qualified industrial cooling service provider during this phase adds valuable technical insight. Sector-specific requirements must be meticulously incorporated into the plan's framework. For food sector cooling applications, the plan must include protocols for sanitary inspections and compliance documentation aligned with production schedules. Plans for energy sector cooling systems need to account for peak demand periods, scheduling major interventions during planned outages. For facilities utilizing custom cooling solutions, the maintenance plan should reference original design specifications to address unique access points and performance parameters. A successful plan establishes clear accountability and documentation procedures. It designates responsible personnel, outlines reporting structures, and implements a tracking system for all maintenance activities and performance data. This documentation creates a valuable historical record that enables predictive analytics, allowing maintenance schedules to be refined over time based on actual equipment behavior rather than generic timelines. This data-driven approach continuously optimizes both resource allocation and system performance. Ultimately, a well-constructed preventive maintenance plan is an investment in operational excellence and financial predictability. It systematically reduces energy consumption, extends equipment lifespan, and eliminates the volatility of emergency repairs. By formalizing maintenance strategies, industrial facilities secure the long-term durability, efficiency, and reliability of their cooling infrastructure, transforming it from a potential liability into a guaranteed asset. Why Choose Günay For Your Cooling System Maintenance Selecting Günay Soğutma for your industrial cooling service provides a fundamental advantage that generic service providers cannot match: direct manufacturer expertise. Our deep involvement in the entire lifecycle of cooling systems, from component production to final installation, grants our technicians unparalleled insight into system optimization and longevity. This intrinsic knowledge transforms routine periodic cooling system maintenance into a precision engineering service that maximizes facility cooling efficiency and ensures truly reliable cooling systems. Our maintenance approach is rooted in the same disciplined manufacturing principles that guide our production. When performing critical evaporator condenser maintenance, we understand the exact tolerances, materials, and design specifications of the components we engineered. This allows for exceptionally precise adjustments and proactive replacements that generic technicians might overlook. Whether servicing systems from our serial production lines or complex custom cooling solutions, our service is informed by original design intent, ensuring performance is restored to factory specifications. We develop preventive maintenance plan strategies that are tailored to specific industrial challenges. For the stringent hygiene and temperature control needs of the food sector cooling, our protocols include compliance-focused checks that safeguard product integrity. For the high-demand, continuous operation requirements of the energy sector cooling, our plans prioritize component stress analysis and predictive failure prevention to avoid costly shutdowns. This sector-specific expertise ensures maintenance directly supports your core business operations. Our service extends beyond checklist tasks to include performance optimization and future-proofing. We analyze operational data to recommend efficiency upgrades, component refinements, and system expansions that align with your evolving production needs. This forward-thinking approach ensures that your cooling infrastructure not only remains operational but continuously improves in efficiency and reliability, protecting your investment against obsolescence. Choosing Günay Soğutma for cooling system maintenance is ultimately a decision for long-term value and operational certainty. Our manufacturer-direct service model eliminates the knowledge gap between design and upkeep, delivering maintenance that enhances energy savings, extends equipment life, and guarantees production stability. Partner with us to secure the full potential of your cooling investment through expert, disciplined care.

Read More