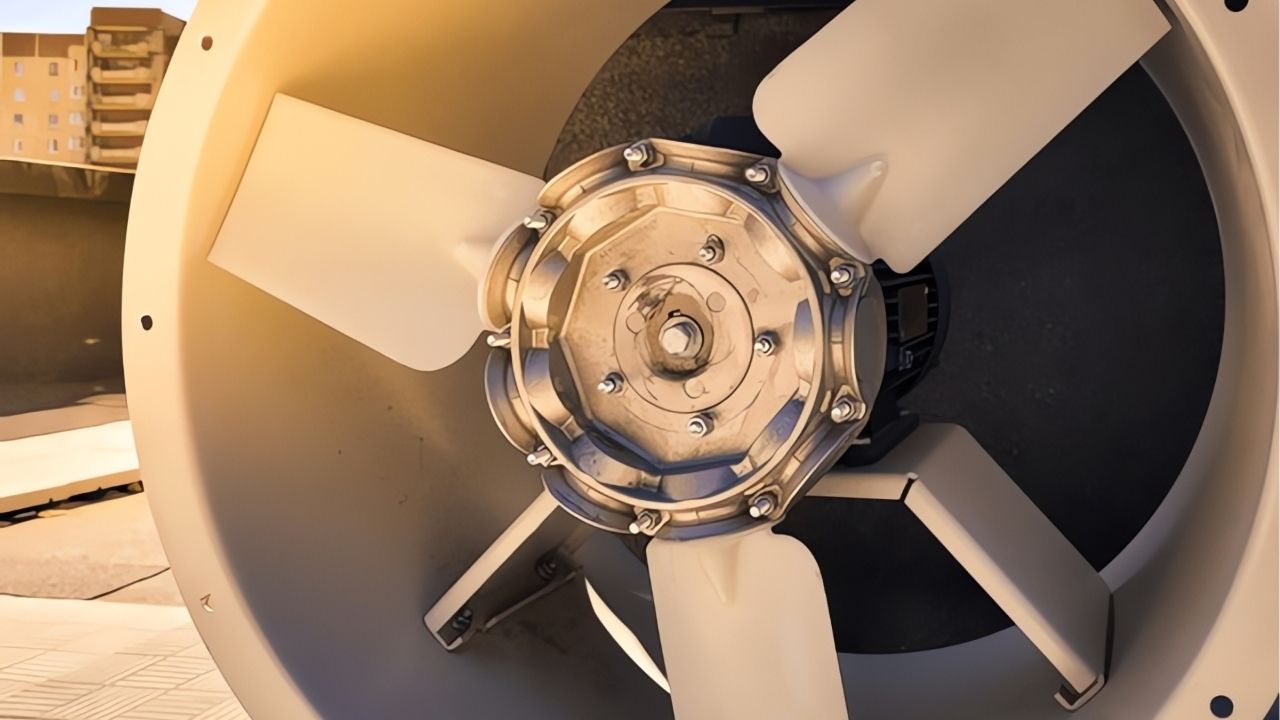

What are Axial Fans? Where are They Used?

Evaporators are vital components in many industrial applications, playing an essential role in separating liquids from gases by utilizing heat. In manufacturing processes, evaporators help remove volatile substances from liquids, concentrating the remaining material. Whether in food processing, chemical production, or HVAC systems, these devices optimize thermal efficiency and ensure operations remain consistent and energy-efficient. With their capacity to transfer heat efficiently, evaporators are crucial in maintaining the right balance of temperature and material properties. As industries advance, the role of evaporators continues to evolve to meet increasing demands for performance and sustainability.

In industrial production, evaporators extend beyond simple liquid removal. By controlling phase changes, they improve production speed and reduce waste. With the growing emphasis on sustainability, efficient evaporators help reduce fuel use and carbon emissions. The role of evaporators in optimizing manufacturing efficiency continues to evolve, making them indispensable to modern industrial processes. Their versatility allows them to meet specific needs in diverse industries, increasing their value in global manufacturing.

Evaporators are essential in many industries, providing a heat transfer mechanism to remove water or solvents from materials. Their design and efficiency directly affect the productivity and energy consumption of production systems. Evaporators are used in food and beverage, pharmaceutical, chemical processing, and HVAC industries, aiding in refining raw materials and concentrating solutions. As industries scale, the demand for energy-efficient evaporators has increased, leading to advancements in technology. This growth has created new opportunities for the development of more energy-efficient and environmentally friendly solutions.

The working principle of evaporators is based on heat transfer, causing liquids to evaporate and leave behind concentrated substances. Modern evaporators are designed for minimal energy consumption and environmental impact. Their role in industrial production continues to expand, making them a cornerstone of efficiency optimization. With advancements in automation and control systems, evaporators now offer higher precision in temperature and pressure management, further enhancing their efficiency.

Evaporators separate components by converting a liquid into vapor using heat, essential for concentrating solutions or distilling chemicals. This process is vital in industries like pharmaceuticals, where consistency is crucial. The liquid is exposed to heat, causing it to vaporize, and the vapor is separated from the liquid. Evaporators help maintain precise product composition, which is critical in many industries. Their ability to control evaporation rates ensures that the final product meets the required standards.

Evaporators come in different designs, such as falling film evaporators, forced circulation evaporators, and flash evaporators, each suited to specific applications. For example, falling film evaporators are used in sensitive products like fruit juices. Efficient evaporation relies on controlling temperature, pressure, and flow rates to achieve optimal conditions for the material. This ensures high-quality, consistent products. Understanding these different evaporator types allows industries to select the most appropriate system for their needs.

There are various evaporator types, each designed for specific needs. Falling film evaporators are common in the food and beverage industry for their efficient liquid evaporation at low temperatures. Forced circulation evaporators are often used for high-viscosity liquids, especially in chemical processing. These systems use a pump to circulate the liquid, ensuring it remains at an optimal temperature and flow rate. Such flexibility in design ensures that each application can achieve the highest efficiency possible.

Flash evaporators are ideal for rapid evaporation of volatile substances by lowering the pressure in the system. These evaporators are common in chemical processing and desalination. Plate evaporators are compact and efficient, suitable for heat-sensitive materials. The choice of evaporator depends on the specific industrial process and its unique needs. With the ongoing advancements in evaporator technology, new hybrid systems are being developed to combine the benefits of multiple evaporator types for enhanced performance.

Efficiency is key in evaporators, as they are responsible for a significant portion of a production system's energy consumption. Efficient evaporators reduce energy use, maximizing vaporized liquid per energy unit. These systems not only lower energy costs but also reduce environmental impact by minimizing fuel use. Energy-efficient evaporators are critical in reducing carbon emissions and meeting sustainability goals. Moreover, reducing energy consumption directly translates to lower operating costs, enhancing the bottom line of manufacturing facilities.

Efficient evaporators contribute to the reliability of production systems. In industries with strict quality and temperature control needs, inefficiencies in the evaporation process can result in product quality issues or production delays. High-performance evaporators ensure continuous operations and product consistency. With real-time monitoring, modern evaporators can adapt to maintain optimal efficiency. This adaptability is vital for keeping production running smoothly and preventing costly interruptions in the supply chain.

Energy-efficient evaporators play a significant role in reducing operational costs. Modern systems optimize heat transfer and capture waste heat, reusing it to further reduce energy consumption. These energy-saving features help meet sustainability goals while lowering carbon footprints. Cost savings can be reinvested into system improvements or production expansion. As industries increasingly focus on environmental responsibility, these systems offer a competitive edge by helping companies maintain profitability and compliance with regulations.

Energy-efficient evaporators also help manufacturers comply with environmental regulations aimed at reducing energy consumption. These systems demonstrate a commitment to sustainability, preventing penalties for non-compliance. The savings realized from energy-efficient evaporators can enhance competitiveness in the market, driving long-term profitability. The adoption of energy-efficient technologies ensures that companies can stay ahead of the curve and maintain operational excellence.

Regular maintenance is crucial for maintaining evaporator performance. Cleaning the surfaces to remove scale or fouling ensures efficient heat transfer. Pump, valve, and sensor inspections help keep the system running smoothly. Proactive maintenance identifies issues early, preventing costly downtime or failures. By implementing a thorough maintenance schedule, production systems can continue to operate efficiently and reduce the risk of unexpected shutdowns.

Maintaining refrigerants and heat transfer fluids is essential for optimal operation and product quality. Routine checks and fluid management ensure the system works effectively. A comprehensive maintenance schedule, including preventive and corrective measures, maximizes the evaporator’s lifespan and minimizes inefficiencies. By regularly replacing worn components and addressing minor issues, manufacturers can extend the life of their evaporators and prevent costly repairs.

Fill out the form to discover the most suitable high-end products for your projects. Contact Us Now.