Axial Fan Types Performance and Application Areas

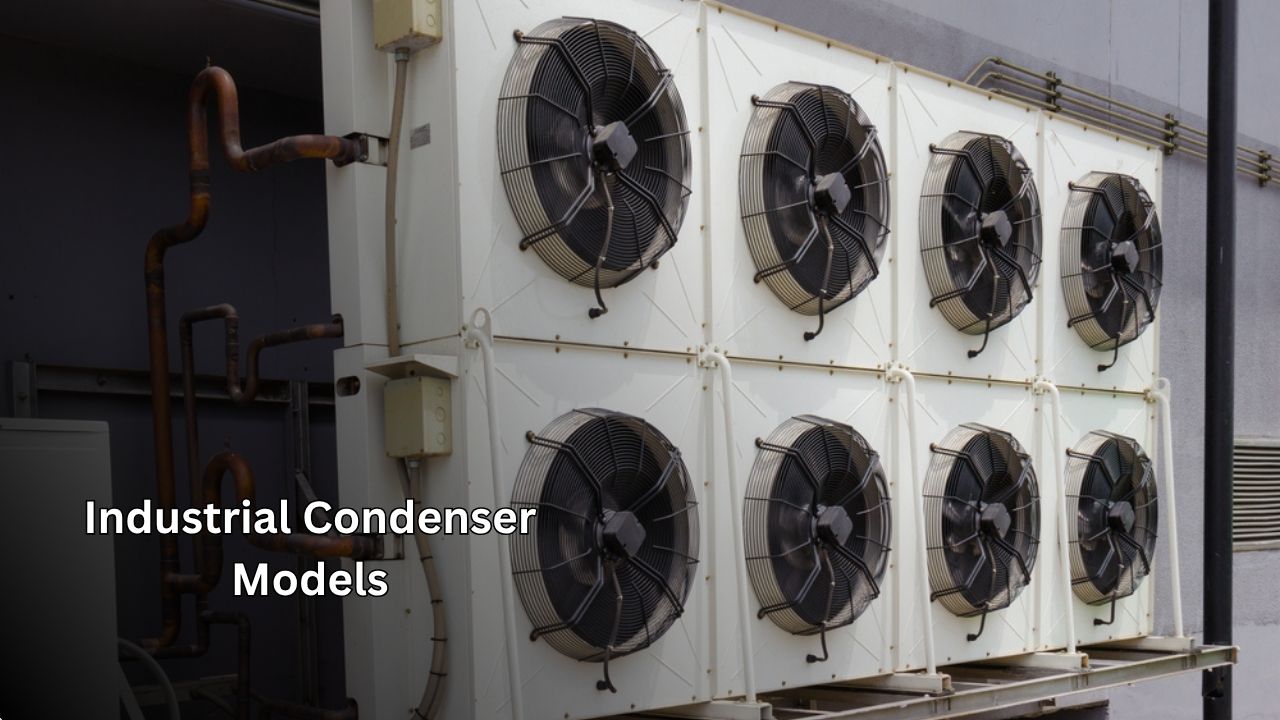

Industrial condenser models vary depending on the application area and the required cooling capacity. Since each sector has different operating conditions and ambient temperatures, selecting the right condenser model is crucial for system efficiency.

Air-cooled condensers are generally preferred in open areas with abundant clean air. These models are widely used in food storage facilities, shopping malls, factories, and cold storage plants. They are easy to maintain, do not require water, and are practical in terms of installation.

Water-cooled condensers stand out in industrial facilities with high heat loads. They are particularly preferred in textile, chemical, pharmaceutical, and energy sectors. Working with cooling towers, they offer higher efficiency. They are an effective solution in enclosed environments where air circulation is insufficient.

Condensers used in industrial cooling systems are mainly divided into two types: air-cooled and water-cooled. Both models operate on the same principle, but there are significant differences in their methods of heat dissipation and areas of application.

Air-cooled condensers dissipate heat to the environment using ambient air. Fans pass external air over heated pipes to transfer heat. Since they operate without water, they are advantageous in terms of installation and maintenance. They are frequently preferred in shopping malls, small industrial facilities, and cold storage warehouses.

Water-cooled condensers remove heat through water circulation. They typically work with a cooling tower and are used in facilities requiring high capacity. Since water provides more efficient cooling, they can offer energy savings. They are preferred in large factories, hospitals, and hotels.

Both models have unique advantages. Choosing the right one based on needs, environmental conditions, and operational priorities ensures efficient and long-lasting system performance.

Industrial condenser selection is a critical decision that directly affects the performance and energy efficiency of the cooling system. Therefore, several key criteria must be considered when selecting a model.

First, the size of the area to be cooled and the system’s capacity requirement must be accurately analyzed. Choosing an unnecessarily large or insufficient condenser can lead to both energy loss and reduced performance. It should be determined whether an air-cooled or water-cooled model is suitable for the application. Air-cooled models are appropriate for systems operating in open areas, while water-cooled options are more efficient in enclosed, high-load systems.

Material quality, corrosion resistance, and thermal conductivity are also important technical factors in the selection process. Additionally, details such as the condenser’s energy consumption, noise level, maintenance ease, and installation dimensions should be considered.

Günay Soğutma determines the most suitable model based on sector-specific needs, offering solutions that ensure high efficiency and long-term use. Proper model selection makes a significant difference in system efficiency and operating costs.

Compact industrial condenser models provide solutions that operate efficiently in limited spaces. Choosing these models in projects requiring space savings enhances both the system’s performance and ease of installation.

These condensers are typically used in cold room systems, supermarket display cases, small production facilities, businesses with limited technical space, and rooftop cooling applications. Their ability to provide strong heat transfer in confined spaces is their most significant advantage. Their portable structure makes both installation and maintenance and service processes quick and efficient.

Compact condenser options developed by Günay Soğutma stand out for their quiet operation and high energy efficiency. These models, which do not take up unnecessary space, are ideal for businesses aiming to reduce energy costs.

Compact condenser models offer practical and effective solutions for projects seeking maximum efficiency in limited spaces. Evaluating these products during system design provides significant long-term advantages.

Günay Soğutma combines high performance and energy efficiency with industrial condenser models developed specifically for the needs of different sectors. Its production portfolio includes both air-cooled and water-cooled models. These two main model groups are designed with different technical specifications based on the application area and system requirements.

Air-cooled condensers are ideal for cooling systems used in outdoor environments. They are widely preferred in food storage facilities, cold storage plants, hotels, and industrial kitchens. Their compact designs deliver effective results even in confined spaces.

Water-cooled condensers stand out in large-capacity facilities. They offer efficient and safe solutions for systems with high heat loads. Preferred in textile, chemical, and energy sectors, these models are notable for their high heat transfer efficiency.

High-capacity industrial condenser models are preferred in large-scale systems requiring continuous cooling. These models are designed to dissipate large amounts of heat quickly and play a critical role in systems operating under heavy loads.

They are typically used in food production facilities, cold storage warehouses, pharmaceutical industries, textile factories, automotive production areas, and power plants. In such systems, efficiency is as important as continuity, so the condenser must be long-lasting, durable, and high-performing.

High-capacity models generally feature multiple fan systems, large-surface heat exchangers, and optimized airflow structures. This maximizes heat transfer while keeping energy consumption balanced.

Modular design provides significant advantages in industrial condenser systems, such as flexibility, easy maintenance, and high efficiency. This structure allows the condenser to consist of independent modular sections, each of which can be activated, replaced, or expanded as needed.

Modular systems offer a significant advantage in projects requiring capacity expansion. Instead of replacing the entire system, only the necessary section can be added, saving both time and cost. Additionally, a technical issue in one module can be addressed without affecting the entire system.

Modular condensers also provide significant ease during installation, as they can be easily integrated into confined spaces or challenging installation points. Their component-based structure makes logistics and transportation processes more practical.

Fill out the form to discover the most suitable high-end products for your projects. Contact Us Now.