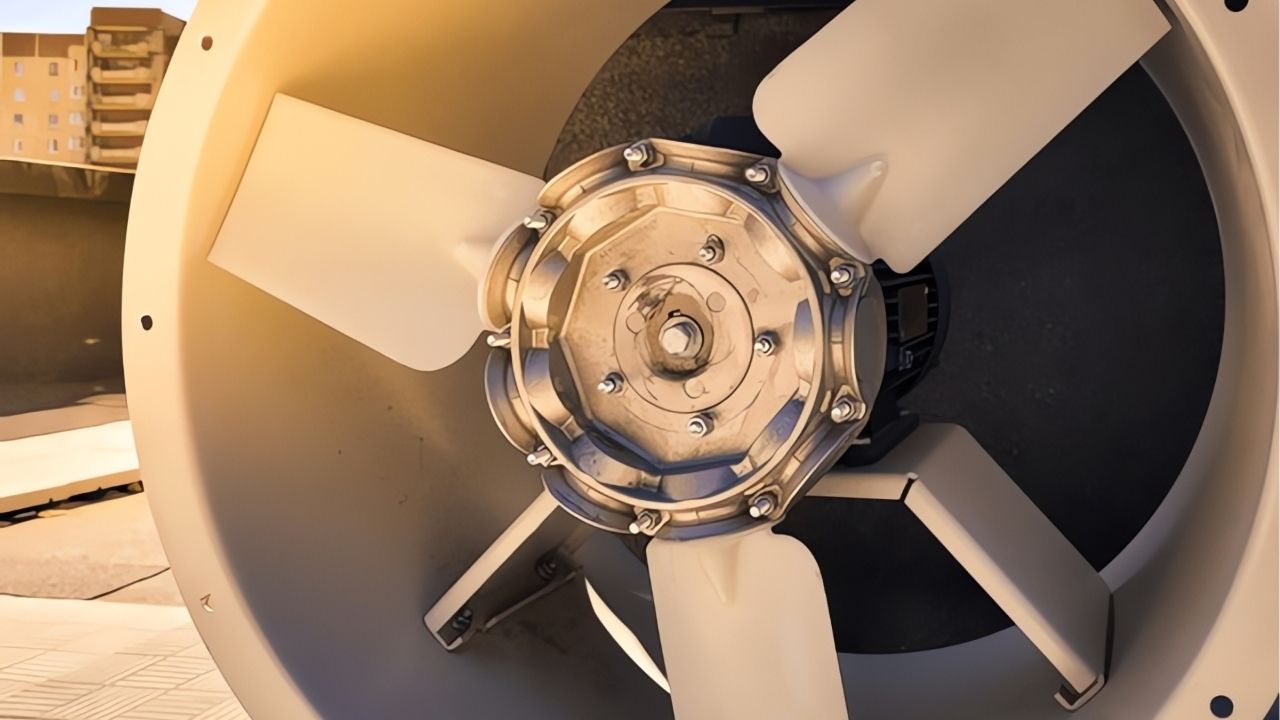

What are Axial Fans? Where are They Used?

Selecting the correct axial fan type is a critical decision for achieving maximum energy efficiency in any industrial cooling system, directly influencing operational costs and environmental footprint. The choice between propeller, vane axial, and tube axial fans hinges on specific performance requirements like static pressure, airflow volume, and system resistance. Understanding axial fan types and performance characteristics is the first step toward reducing energy consumption and enhancing the overall reliable cooling infrastructure of a production facility.

For most industrial cooling fan applications requiring high airflow at low to medium static pressures, vane axial fans often deliver superior efficiency. Their guided vanes recover static pressure by straightening the airflow, allowing the fan to move more air with less power compared to a simple propeller fan. This makes them ideal for applications supporting high-efficiency condenser evaporator units, where consistent, optimized airflow is essential for peak heat transfer. Investing in these energy saving fan types translates directly into lower kilowatt-hour consumption and a smaller carbon footprint.

The pursuit of ultimate efficiency often leads to a custom axial fan application, where the fan is engineered to match the precise aerodynamic profile of the cooling system. This level of precision is a hallmark of Günay Soğutma axial fan production, which utilizes advanced design and testing to ensure optimal performance. A durable axial fan built with robust materials and precision-balanced impellers not only saves energy but also operates quietly and with minimal vibration, extending the life of the entire assembly.

Ultimately, the most energy-efficient axial fan is the one perfectly suited to its specific duty point within your system. An improperly selected fan will waste energy, generate excessive noise, and potentially cause premature failure. By consulting with experts and selecting a fan based on rigorous performance data, you can ensure your cooling system operates at its thermodynamic peak, delivering reliable performance while minimizing lifetime operating expenses.

Understanding axial fan performance is fundamental to designing a system that achieves high-efficiency cooling and realizes significant lower operational costs. The selection process must carefully balance airflow requirements, static pressure demands, and acoustic considerations to ensure the fan operates at its best efficiency point. This guide provides a framework for evaluating axial fan types and performance curves to make an informed choice that supports a reliable cooling infrastructure and minimizes energy waste.

The first step is to accurately define the system's requirements, including the required cubic feet per minute (CFM) of airflow and the static pressure the fan must overcome. This is particularly critical for industrial cooling fan applications involving a high-efficiency condenser evaporator, where insufficient airflow can drastically reduce heat exchange efficiency and increase compressor load. For such demanding roles, energy saving fan types like vane axial models are often preferred due to their ability to handle higher pressures more efficiently than basic propeller fans.

When standard offerings do not perfectly match the system curve, a custom axial fan application becomes the optimal path. This approach, central to Günay Soğutma axial fan production, involves tailoring the blade angle, diameter, and hub ratio to achieve peak performance for a specific set of conditions. The result is a durable axial fan that operates with lower power consumption, reduced noise, and minimal vibration, contributing to extended equipment life and lower maintenance costs.

By meticulously selecting the right axial fan based on performance data rather than approximate sizing, facilities can secure long-term financial and operational benefits. The correct fan ensures that the cooling system works as intended, preventing energy overuse and mechanical stress. This proactive investment in performance-optimized components is a proven strategy for enhancing system reliability, achieving sustainability goals, and maintaining a competitive edge through controlled operating expenses.

The strategic selection of axial fan types is paramount for maximizing airflow efficiency and ensuring extended equipment lifespan in industrial settings. Each fan category—propeller, tube axial, and vane axial—possesses distinct axial fan types and performance characteristics suited to specific pressure and flow requirements. Matching the correct fan to its industrial cooling fan applications prevents system strain, reduces energy consumption, and forms the basis of a reliable cooling infrastructure.

Propeller fans excel in moving large volumes of air against very low static pressure, making them suitable for general ventilation. However, for forced-draft applications critical to high-efficiency condenser evaporator performance, vane axial fans are superior. Their incorporated guide vanes straighten airflow, recovering pressure and allowing the unit to operate efficiently against the resistance of dense coil fins. These energy saving fan types are essential for maintaining optimal heat transfer rates without overloading the motor, directly impacting the system's overall energy draw.

In scenarios with unique spatial constraints or abnormal operating conditions, a custom axial fan application provides the perfect solution. This engineering-centric approach, a specialty of Günay Soğutma axial fan production, tailors the fan's aerodynamics and structure to the exact application. The outcome is a durable axial fan that delivers precise airflow while operating with minimal vibration and acoustic noise, factors that significantly contribute to the longevity of the fan itself and the surrounding structure.

Ultimately, understanding the correlation between fan selection, efficiency, and durability allows facility managers to make capital investments that yield long-term returns. A correctly applied fan minimizes power costs, reduces the need for frequent maintenance, and prevents premature failure of both the fan and the components it serves. This informed approach to component selection is a cornerstone of building a cost-effective, high-performance industrial cooling system designed for years of reliable service.

The choice between standard and custom axial fans represents a fundamental trade-off between initial cost and long-term performance, directly impacting cooling reliability and energy savings. Standard fans offer a quick, cost-effective solution for applications with common requirements, but they may operate away from their peak efficiency if system parameters are not a perfect match. A performance comparison reveals that for critical industrial cooling fan applications, a tailored solution often delivers superior operational and financial outcomes.

Standard axial fans are mass-produced to cover a wide range of general axial fan types and performance needs, making them suitable for basic ventilation or systems with forgiving performance tolerances. However, when integrated with a high-performance high-efficiency condenser evaporator, a standard fan might not provide the precise airflow and pressure required, leading to reduced heat exchange and higher energy consumption. In contrast, a custom axial fan application is engineered from the outset to meet the exact system curve, ensuring it operates as one of the true energy saving fan types.

The engineering process for a custom fan, as exemplified by Günay Soğutma axial fan production, involves optimizing the blade profile, hub ratio, and materials for the specific application. This results in a durable axial fan that not only consumes less power but also exhibits lower vibration levels and noise, contributing to a more stable reliable cooling infrastructure. The precision balancing and robust construction inherent in custom fans directly extend the operational life of the unit and its supporting structure.

While the upfront investment for a custom fan is higher, the long-term benefits in energy efficiency, reduced maintenance, and unwavering reliability typically yield a significantly lower total cost of ownership. For facilities where cooling is integral to production, the enhanced performance and predictability of a custom solution provide a substantial return on investment, making it the strategically sound choice for ensuring continuous, cost-effective operation.

Optimizing axial fan selection is a proactive engineering strategy to achieve dual objectives significant reduced maintenance downtime and consistent higher cooling performance. This process requires moving beyond basic airflow specifications to consider factors like operational environment, bearing technology, and impeller balance. A methodical approach to selection, grounded in a deep understanding of axial fan types and performance, directly contributes to a more robust and reliable cooling infrastructure.

The foundation of optimization is accurate system characterization. Engineers must calculate the exact static pressure and airflow (CFM) required for optimal operation of key components like the high-efficiency condenser evaporator. Selecting a fan that operates at its best efficiency point for these conditions is crucial; an undersized fan will strain to meet demand, while an oversized one will waste energy and potentially recirculate air. For complex industrial cooling fan applications, this often leads to the specification of energy saving fan types like vane axial models, which offer superior pressure capabilities.

To minimize maintenance, priority must be given to features that enhance durability. This includes specifying a durable axial fan constructed with corrosion-resistant coatings, premium bearings with extended service life, and a dynamically balanced impeller to prevent vibration-induced wear. In non-standard installations, a custom axial fan application ensures these features are integrated seamlessly. This level of precision manufacturing is a cornerstone of Günay Soğutma axial fan production, where discipline ensures every fan is built for longevity.

By following this optimized selection protocol, facilities effectively invest in predictability. The right fan operates smoothly, reduces the stress on motors and drives, and maintains designed airflow for peak heat transfer efficiency year after year. This translates into fewer emergency repairs, lower spare parts inventory, and a cooling system that reliably supports production targets, ultimately delivering a lower total cost of ownership and enhanced operational control.

Axial fans are indispensable components for boosting efficiency and sustainability ROI in the food and energy sectors, where cooling reliability directly impacts product quality, safety, and power generation. The correct application of specific axial fan types and performance profiles is critical for managing unique environmental challenges, from hygienic requirements in food processing to heat rejection in power plants. This guide outlines how strategic fan selection underpins a reliable cooling infrastructure that delivers both operational and environmental returns.

In the food sector, industrial cooling fan applications demand fans that support precise temperature control for blast freezers, chillers, and maturation rooms. These systems often utilize high-efficiency condenser evaporator units where consistent, robust airflow is non-negotiable. Here, energy saving fan types with corrosion-resistant coatings and easy-clean designs are essential. For complex layouts, a custom axial fan application ensures optimal performance while adhering to stringent hygiene protocols, a standard upheld in Günay Soğutma axial fan production.

The energy sector presents different challenges, with axial fans critical for cooling turbines, transformers, and large-scale process heat exchangers. These applications require a durable axial fan capable of withstanding harsh outdoor conditions, variable loads, and continuous operation. The sustainability ROI is calculated through reduced auxiliary power consumption and increased availability of the primary power-generating asset. Precision-engineered fans minimize the parasitic load they represent, making the entire energy production process more efficient and profitable.

By viewing axial fans not as commodities but as engineered solutions, businesses in both sectors can achieve remarkable gains. The investment in a correctly specified, high-quality fan pays dividends through lower energy bills, compliance with environmental standards, reduced water consumption in evaporative systems, and unparalleled equipment reliability. This strategic approach transforms the axial fan from a simple component into a key driver of sustainable, cost-effective industrial operations.

Mastering key axial fan performance metrics is the definitive method for achieving long-lasting durability and securing lower energy expenses in industrial cooling systems. These quantifiable measurements—including airflow (CFM), static pressure, fan efficiency, and sound power level—provide an objective framework for selection far superior to guesswork. A data-driven approach grounded in a thorough understanding of axial fan types and performance ensures the fan operates harmoniously within the reliable cooling infrastructure, avoiding the inefficiencies that lead to high costs and premature failure.

The primary metric is the system curve, which defines the relationship between required airflow and the static pressure the fan must overcome. Accurately plotting this curve for your specific industrial cooling fan applications is the first step. The ideal fan selection is one whose performance curve intersects the system curve at or near its peak efficiency point. This is especially critical when the fan serves a high-efficiency condenser evaporator, as improper airflow can degrade the entire system's thermal performance. Choosing from true energy saving fan types based on this data guarantees minimal power consumption.

Durability metrics focus on mechanical integrity. These include impeller balance grades (e.g., ISO 1940 G6.3 or better) to minimize vibration, and bearing life calculations (L10 life) based on operational speed and load. For challenging environments, a custom axial fan application allows for the optimization of these parameters. This engineering precision, a hallmark of Günay Soğutma axial fan production, results in a durable axial fan that withstands continuous operation without degradation in performance or reliability.

By rigorously applying these performance metrics during the selection process, facility managers make an investment that pays continuous returns. The correctly specified fan uses less electricity, requires less maintenance, and operates reliably for its entire design life. This methodology transforms the axial fan from a potential source of problems into a cornerstone of an efficient, predictable, and cost-effective industrial cooling operation.

Fill out the form to discover the most suitable high-end products for your projects. Contact Us Now.