What are Axial Fans? Where are They Used?

For industrial facility managers, the initial evaporator price is merely the entry point to a far more critical calculation total cost of ownership. A truly accurate comparison must extend beyond the invoice to evaluate how the component's design and materials will impact long-term energy consumption and operational reliability. This requires a disciplined analysis of thermal efficiency, corrosion resistance, and compatibility with the entire cooling infrastructure solutions. By prioritizing these factors, businesses can achieve maximum energy efficiency and ROI, transforming a capital expenditure into a strategic investment in production stability.

The heart of an industrial evaporator quote lies in its engineering specifications, which dictate performance under demanding conditions. Facilities should scrutinize the heat transfer surface area, fin density, and tube materials, as these directly influence the system's ability to maintain precise temperatures with minimal energy input. A well-designed evaporator, often part of a comprehensive package that includes durable condenser price considerations, forms the core of energy efficient cooling systems. These components work synergistically to reduce electrical loads, lower operational expenses, and ensure consistent performance in food processing or energy generation applications.

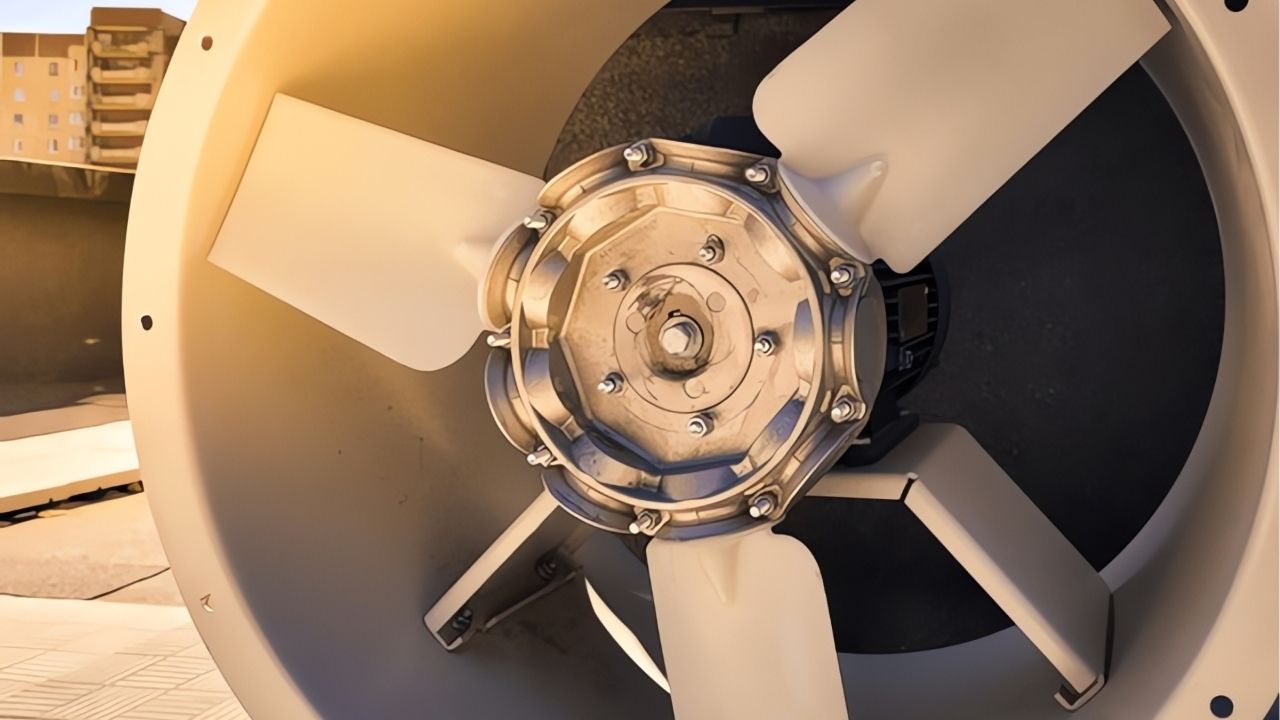

Modern manufacturing flexibility is paramount, as a one-size-fits-all approach rarely delivers optimal results. This is where the distinction between standard and custom evaporator production becomes a significant value driver. Custom solutions allow for precise tailoring to specific thermal loads, spatial constraints, and process requirements, eliminating inefficiencies inherent in poorly matched off-the-shelf units. Established manufacturers like Günay Soğutma leverage this capability to deliver systems that integrate seamlessly with supporting components like axial fan and resistance production, ensuring balanced airflow and electrical safety for a truly robust cooling circuit.

Ultimately, the most strategic price comparison evaluates durability and ease of maintenance as primary cost factors. A higher initial investment in a premium evaporator constructed with robust materials and advanced manufacturing techniques pays dividends through extended service intervals, reduced downtime, and a longer operational lifespan. This forward-thinking approach, championed by experienced providers, safeguards production uptime and delivers sustained returns by minimizing lifetime operational costs and strengthening the facility's overall cooling resilience.

An accurate assessment of an industrial evaporator quote requires a deep understanding of the five critical factors that govern both initial expenditure and long-term operational performance. These determinants transform a simple component evaporator price into a strategic investment, directly influencing energy consumption, maintenance frequency, and the overall reliability of your cooling infrastructure solutions. For production line managers, ignoring these variables risks unexpected downtime and inflated operational costs, making a disciplined evaluation essential for achieving sustainable cooling efficiency.

The first factor is thermal design efficiency, which dictates the unit's heat transfer capability and its contribution to energy efficient cooling systems. A higher efficiency design, often achieved through advanced fin patterns and optimized tube layouts, requires less energy to achieve the same cooling load, directly reducing electricity costs. The second factor is material selection and corrosion resistance, a critical consideration in demanding environments like food processing where equipment longevity is paramount. Using superior materials ensures durability and aligns the evaporator's lifecycle with that of a durable condenser price analysis for a balanced system investment.

Manufacturing capability forms the third factor, where the option for custom evaporator production allows for precise adaptation to specific spatial and thermal requirements, eliminating performance compromises. This flexibility is a hallmark of established manufacturers like Günay Soğutma, who integrate modern technology with disciplined production. The fourth factor is compatibility and integration with auxiliary components, particularly those from integrated axial fan and resistance production lines, which ensure optimal airflow and system harmony for peak performance.

The fifth and often most overlooked factor is the design for serviceability and ease of maintenance. An evaporator engineered for straightforward cleaning and part replacement drastically reduces maintenance downtime and labor costs, protecting production schedules. Ultimately, a comprehensive evaluation of these five factors ensures that the selected evaporator delivers not just immediate cooling but long-term operational stability and cost control, solidifying the cooling system as a pillar of production reliability.

The initial evaporator price on an invoice represents only a fraction of its true financial impact on an industrial operation. The real metric for procurement decisions must be long-term value, calculated through a disciplined analysis of energy consumption, maintenance intervals, and operational uptime over the equipment's entire lifecycle. For facility managers, this shift in perspective from price to value is crucial for building robust and economical cooling infrastructure solutions. A premium evaporator, while commanding a higher initial industrial evaporator quote, often delivers substantially lower total cost of ownership by ensuring reliability in demanding production environments.

Calculating long-term savings begins with evaluating the unit's contribution to energy efficient cooling systems. Superior thermal design directly reduces compressor workload and electricity costs, a saving that compounds annually. This efficiency must be considered alongside the durable condenser price to assess the synergistic performance of the entire circuit. The value equation is further refined by the option for custom evaporator production, which eliminates performance gaps and inefficiencies that plague generic solutions, ensuring every kilowatt of energy is utilized effectively.

The manufacturing philosophy behind the components is a critical value driver. Established producers like Günay Soğutma integrate disciplined engineering with high-quality materials to maximize service life and minimize unplanned downtime. This approach extends to companion components from their integrated axial fan and resistance production lines, creating a harmonious system where each part reinforces the other's durability and performance. This holistic engineering focus prevents costly cascade failures and protects continuous production schedules.

Ultimately, the most accurate calculation of value incorporates the avoided costs of production interruptions, emergency repairs, and premature replacement. An evaporator built for long-lasting performance safeguards against these financial drains, translating a higher initial investment into predictable, lower operational expenses. By prioritizing engineering excellence and durability, businesses can secure not just a cooling component, but a foundational element of production stability and long-term profitability.

Securing an accurate and beneficial industrial evaporator quote requires a meticulously prepared specification that prioritizes long-term performance over the initial evaporator price. The objective of custom evaporator production is to engineer a solution that explicitly targets lower maintenance demands and higher durability, transforming the component into a cornerstone of reliable cooling infrastructure solutions. A well-defined specification sheet acts as a blueprint for manufacturers, guiding them to deliver a unit that minimizes lifecycle costs and maximizes uptime for your specific application.

The specification process must begin with a precise definition of the operational environment, including ambient temperature, potential corrosive elements, and required cleanliness standards, especially in food sector applications. This environmental data directly informs material selections, such as specific coil coatings or stainless-steel alloys, that combat corrosion and fouling, thereby extending service intervals. Furthermore, the thermal load and desired temperature differentials must be clearly stated to ensure the design achieves the necessary efficiency for integration into energy efficient cooling systems.

Critical technical details that directly impact maintenance and durability include specifying fin density for optimal balance between heat transfer and cleanability, access points for inspection and cleaning, and corrosion-resistant fasteners. It is also prudent to inquire about compatibility with other system components, as a harmonized system involving a durable condenser price and components from integrated axial fan and resistance production ensures balanced performance. Manufacturers with proven expertise, such as Günay Soğutma, can provide valuable guidance on these specifications based on years of disciplined manufacturing.

Ultimately, a comprehensive specification empowers you to receive a quote that reflects a true partnership in engineering reliability. By detailing requirements for durability and ease of service, you guide the manufacturer toward a solution that reduces total cost of ownership. This proactive approach to specifying a custom evaporator ensures the final product is not just a component, but a durable, low-maintenance asset that protects your production integrity and delivers sustained operational savings.

A meaningful industrial evaporator quote comparison demands an analytical framework that extends far beyond the initial evaporator price to account for projected energy consumption over the equipment's operational lifespan. This holistic analysis reveals that the most economical choice is rarely the cheapest upfront, but rather the unit engineered for peak efficiency as part of integrated cooling infrastructure solutions. The discipline of calculating lifetime energy savings transforms procurement from a simple purchase into a strategic decision that directly impacts a facility's operating margin and sustainability profile.

The primary driver of lifetime cost is thermal efficiency, a metric dictated by design sophistication and manufacturing precision. A high-efficiency evaporator requires less energy to achieve the same cooling capacity, leading to significant annual electricity savings that quickly offset a moderately higher initial investment. This efficiency is a core component of truly energy efficient cooling systems and should be evaluated with the same rigor as the accompanying durable condenser price to ensure system-wide harmony. The option for custom evaporator production further optimizes this balance by tailoring the unit to exact operational parameters, eliminating energy waste from over-sized or under-performing generic models.

True comparative analysis also incorporates the reliability offered by manufacturers with integrated capabilities, such as those who manage their own axial fan and resistance production. This vertical integration, a hallmark of established firms like Günay Soğutma, ensures component compatibility and system-wide durability, preventing energy losses from mismatched parts. A reliable system avoids the hidden costs of unplanned downtime and emergency repairs, which can dwarf any minor savings from a lower-quality initial purchase.

Ultimately, the most financially sound decision emerges from a disciplined comparison that weighs the present cost against a decade or more of future operational expenses. Investing in a high-efficiency, durable evaporator secures predictable energy costs and protects production continuity. This forward-looking approach to procurement ensures that your cooling infrastructure becomes a source of competitive advantage through lower total cost of ownership and enhanced operational resilience.

Before requesting an industrial evaporator quote, a strategic set of questions must be prepared to ensure the resulting proposal delivers genuine value beyond the basic evaporator price. These inquiries are designed to uncover the manufacturer's capability to deliver a solution that enhances your entire cooling infrastructure solutions with a focus on longevity and efficiency. A disciplined questioning process separates suppliers who offer commodity products from those who provide engineered solutions aimed at reducing total cost of ownership and safeguarding production uptime.

The first line of questioning should target thermal performance and energy metrics. Inquire about the specific design features that contribute to energy efficient cooling systems, such as heat transfer coefficients and the expected temperature differential under full load. It is equally critical to ask about material specifications and corrosion protection, especially if the unit will operate in a harsh environment, as this directly impacts the durable condenser price and system-wide lifespan. Questioning the availability and process for custom evaporator production is essential to determine if the unit can be tailored to your spatial and performance constraints.

Further due diligence involves understanding the manufacturer's integration capabilities and quality control. Ask about their in-house production of auxiliary components, such as axial fan and resistance production, to gauge system harmony and reliability. For established manufacturers like Günay Soğutma, this vertical integration is a key indicator of disciplined manufacturing and consistent quality. Inquire about standard warranties, availability of spare parts, and the design philosophy regarding serviceability to assess long-term maintenance costs and operational risks.

Ultimately, the answers to these questions will paint a clear picture of whether the proposed evaporator is a short-term expense or a long-term investment. A comprehensive quote backed by clear, technical answers demonstrates a partnership focused on your operational success. This preparatory work ensures the selected solution will deliver not just immediate cooling, but sustained performance, energy savings, and reliability that protects your production line's output and profitability for years to come.

The direct correlation between evaporator price and its underlying design philosophy is the most critical factor in determining long-term operational expenses. A sophisticated design, reflected in a detailed industrial evaporator quote, incorporates advanced engineering principles that directly translate into lower energy consumption, reduced maintenance频率, and extended service life. These design choices are investments that amortize over the lifespan of the equipment, making a well-engineered unit a foundational element of cost-effective cooling infrastructure solutions for any production line.

Key design elements that influence both cost and performance include heat exchanger geometry, fin density, and tube material selection. An optimized design maximizes surface area for heat transfer, allowing the compressor to work less and consume significantly less electricity, a core benefit of energy efficient cooling systems. This efficiency must be evaluated in tandem with the durable condenser price to ensure a balanced system. The option for custom evaporator production allows for precise tailoring of these elements to specific thermal loads and spatial constraints, eliminating the performance penalties and energy waste of ill-fitting standard units.

Beyond thermal efficiency, design decisions regarding corrosion resistance, cleanability, and structural integrity have a profound impact on maintenance costs and downtime. Features like enhanced coatings, accessible headers, and robust construction, often championed by manufacturers like Günay Soğutma, prevent frequent servicing and premature failure. Furthermore, a design that ensures compatibility with components from integrated axial fan and resistance production lines promotes system harmony, preventing energy losses and stress points that lead to increased operational expenses.

Ultimately, the higher initial cost of a superior evaporator design is not an expense but a strategic allocation toward future savings. Every design feature aimed at efficiency and durability directly reduces the lifetime cost of ownership. By prioritizing engineering excellence in the procurement phase, industrial facilities secure not just a cooling component, but a reliable, low-maintenance asset that delivers sustained operational savings and protects production integrity for years to come.

A disciplined, checklist-based approach is essential for accurately comparing industrial evaporator quote proposals and ensuring your investment achieves peak cooling efficiency. This methodology shifts the focus from the isolated evaporator price to a comprehensive evaluation of how the unit will perform as the core of your cooling infrastructure solutions. By systematically verifying key technical, manufacturing, and service criteria, facility managers can select a solution that guarantees long-term energy savings, operational reliability, and minimal maintenance overhead.

The first section of the checklist must verify thermal performance credentials. Confirm the stated heat transfer capacity, refrigerant compatibility, and the specific design features that qualify the unit for integration into energy efficient cooling systems. This performance data should be contextualized with the associated durable condenser price to assess system synergy. A critical item is confirming the scope and flexibility of custom evaporator production to ensure the design can be tailored to your exact spatial and load requirements, eliminating efficiency losses from generic fits.

The second section evaluates manufacturing quality and integration potential. Investigate the supplier's in-house capabilities, particularly for critical supporting components like axial fan and resistance production, as this indicates control over quality and system harmony. For proven manufacturers like Günay Soğutma, this vertical integration is a hallmark of disciplined production. This section should also include verification of material certifications, corrosion protection specifications, and design features that facilitate easy cleaning and maintenance to reduce long-term operational costs.

The final checklist items concern lifecycle support and total cost of ownership. Compare warranty terms, availability of spare parts, and projected service intervals. A superior quote will transparently address these long-term value factors, demonstrating that the solution is engineered for durability, not just initial sale. Applying this definitive checklist ensures the selected evaporator becomes a reliable, high-efficiency asset that delivers sustained performance, protects production uptime, and maximizes return on investment through lower operational expenses over its entire service life.

Fill out the form to discover the most suitable high-end products for your projects. Contact Us Now.