What are Axial Fans? Where are They Used?

Condenser units are components that play a critical role in refrigeration and air conditioning systems. Their main function is to ensure the evaporation of the cooling fluid and to remove the heat generated as a result of this process. Condenser units are usually a heat exchanger ve fan Contains. During the process, the refrigerant exists in the form of high-pressure and hot gas when evaporated by the evaporator. This gas is directed to the condenser units where it transfers heat to ambient air. This heat transfer causes the cooling fluid to condense and become liquid.

The working principle of condenser units can be explained simply: Cooling fluid, condenser coils As it circulates inside, it releases heat to the environment with the air blown by the fans. This process ensures that the system can cool efficiently. condenser units, air cooled or water cooled There are two main types. In air-cooled units, heat is released through air, while in water-cooled units, heat is released using cooling water. These units are designed to provide high performance and energy efficiency and are used in a variety of industrial and commercial applications.

The basic functions of condenser units play a critical role in ensuring the effective operation of refrigeration and air conditioning systems. First, condenser units condensation of the cooling fluid provides. The high pressure gas evaporated by the cooling system is directed to the condenser unit where it transfers heat to the environment. This heat transfer causes the gas to condense into liquid, thus making the cooling fluid usable again.

Second, condenser units releases heat to ambient air or water, thus increasing the efficiency of the cooling system. In air-cooled units, heat is transferred with air blown by fans, while in water-cooled units, heat is removed using water. Third, condenser units regulates system pressure and temperature, which ensures that the system operates safely and efficiently. Moreover, Modern technologies that optimize energy efficiency By using it, energy consumption is reduced and performance is increased. Condenser units provide high performance and reliability in industrial and commercial cooling systems, extending the overall efficiency and life of the systems.

The selection of condenser unit types should be based on specific needs and application requirements. Air cooled condensing unitsis the most commonly used type and is generally known for its low maintenance requirements. These units transfer heat with the outside air and are easy to install. Generally commercial buildings ve industrial facilities It is used in large areas such as On the other hand, water cooled condensing unitsprovides greater energy efficiency because it transfers heat to water, resulting in lower operating temperatures and higher performance. Water cooled units, large scale industrial facilities ve data centers It is preferred in applications such as

Another option is dual phase condensing units It combines both water and air cooling methods. Such units provide flexibility in variable weather conditions and energy saving provides. M.modular condenser unitsioffers flexibility and scalability with multiple unit combinations, making them growing facilities ve application changes makes it suitable for When choosing the type of condensing unit that suits your needs, it is important to consider factors such as energy efficiency, maintenance requirements and size of the application area.

Various strategies can be implemented to increase energy efficiency with condenser units. Firstly, high efficiency condensing units should be selected. These units minimize energy consumption and optimize performance using modern technologies. Energy saving fans ve variable speed controlled motorsIt plays an important role in increasing the energy efficiency of condenser units. Moreover, regular maintenance and cleaningensures efficient operation of the units; Dirty heat exchangers and clogged filters increase energy consumption, reducing efficiency.

With this, heat recovery systems Using it can increase the energy efficiency of condensing units. These systems save energy by reusing waste heat and reduce total energy consumption. Working conditions suitable for outdoor temperature Creating also increases energy efficiency; condensing units must be optimized according to the ambient temperature. Moreover, intelligent control systems ve automatic adjustment mechanisms Monitoring and adjusting the performance of units in real time increases energy efficiency. These strategies enable condensing units to operate more sustainably and economically.

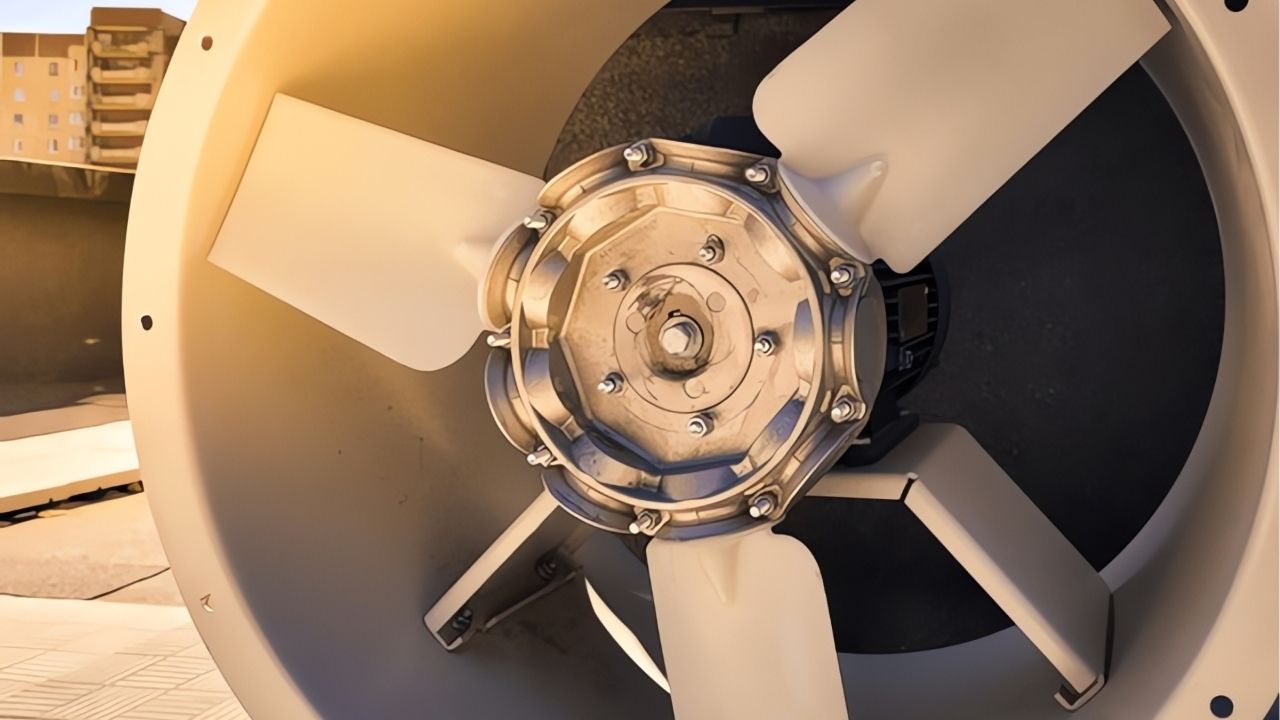

Regular maintenance and cleaning are vital for long-lasting and efficient operation of condenser units. Firstly, regular cleaning of condenser coils must be provided. Dust and dirt accumulated in the coils prevent heat transfer, reducing energy efficiency. Therefore, coils should be cleaned at least once a year and professional cleaning services should be used if necessary. Moreover, fan blades and motors Cleaning ensures proper air flow and increases the performance of the system. Fans and motors must be cleaned of dust and dirt.

Checking filters regularly and it is also important to clean it; Clogged filters block airflow and put extra load on the unit. water levels ve leak check If any leakage or low water level is detected in water-cooled systems, immediate action must be taken. Moreover, Protective covers suitable for outdoor conditions ve general checks several times a yearIt helps protect the units from external factors and keep the performance constantly high. By following these maintenance and cleaning tips, the efficiency of condenser units can be increased and long-lasting performance ensured.

Condenser units play an important role in cooling and air conditioning systems with their various advantages. Firstly, energy efficiency they provide; modern condensing units reduce costs and reduce environmental impact by using technologies that optimize energy consumption. Moreover, low maintenance They are known for; Air-cooled units generally have low maintenance and the systems operate reliably for long periods of time.

high performance They provide effective cooling in large areas. Water-cooled condenser units offer high performance and efficiency, especially in large-scale industrial facilities and data centers. Moreover, flexible use offers the advantage; Different types of condensing units can be adapted to varying needs and provide effective performance in different environmental conditions. Environmentally friendly technologies By using it, they manage waste heat more efficiently and support environmental sustainability.

Temperature control and performance management of condensing units are critical to ensuring the efficiency and reliability of the system. Firstly, temperature sensors and control panels Using this method, the temperature of the condenser unit is constantly monitored. These sensors detect temperature changes within the unit and transmit them to the control panels, ensuring that the system remains at optimum operating temperature. Variable speed fans ve compressorsmanages performance and optimizes energy consumption by quickly responding to temperature changes.

During temperature control, outdoor temperature is also taken into consideration. Most modern condensing units, intelligent control systems Equipped with; These systems increase the efficiency of the system by making automatic adjustments according to external environmental conditions. Moreover, regular maintenance and cleaning, improves unit performance; Dirty coils and clogged filters make temperature control difficult and reduce energy efficiency. System performance monitoring software Using it, unit performance is monitored in real time and necessary adjustments are made. These methods effectively manage the temperature control and overall performance of condensing units.

High efficiency condensing units have various advanced features to provide energy savings and performance optimization. First, these units variable speed fans ve compressors Equipped with. These features minimize energy consumption and increase performance by adjusting fan and compressor speed according to the operating conditions of the system. High performance heat exchangersBy optimizing heat transfer, it provides more efficient cooling and reduces energy losses.

Additionally, in high efficiency models intelligent control systems is found; These systems increase energy efficiency by making automatic adjustments according to outdoor conditions and indoor temperature requirements. Advanced insulation materials ve low noise levels Additional features such as provide energy savings and increase environmental comfort. Energy efficiency classes Compliant with , these units verify their performance against international standards and reduce energy costs. These features enable high-efficiency condensing units to deliver superior performance in a variety of industrial and commercial applications.

Various technologies are used to save energy in condenser units. Firstly, variable speed control technologyis an important innovation that increases energy efficiency. This technology optimizes energy consumption and prevents unnecessary energy expenditure by adjusting the speed of fans and compressors according to the current load and environmental conditions. Intelligent control systems It also saves energy; these systems monitor outdoor temperatures and indoor air conditions in real time and automatically adjust unit performance.

High efficiency heat exchangers ve optimized coil designs It plays a critical role in energy saving; These elements provide higher performance with less energy by increasing heat transfer. Moreover, energy recovery systemsBy reusing waste heat, it increases energy efficiency and reduces total energy consumption. Advanced insulation materials It minimizes heat losses and increases cooling performance.

The installation process of condensing units is critical to performance and efficiency and includes several critical steps. Firstly, Choosing the right layout and mounting location should be done. Condenser units must be in a location where sufficient air flow can be provided and protected from extreme temperature effects. Moreover, high efficiency insulation materials It is important to minimize heat loss and increase energy efficiency by using

During installation, Correct electrical and cooling connections must; This directly affects unit performance and ensures safety. Proper piping and leak checks should also be done; Pipe connections must be solid and leak-proof to ensure efficient cooling. Level and alignment checks of condenser units Correct operation and long-lasting performance of the units must be ensured.

Fill out the form to discover the most suitable high-end products for your projects. Contact Us Now.