Resistance Life Enchance: Operation Maintenance and Savings Tips

Heat exchangers are devices that facilitate heat transfer between two different fluids and are widely used in industry to enhance energy efficiency. These systems optimize temperature balance by transferring heat from one fluid to another.

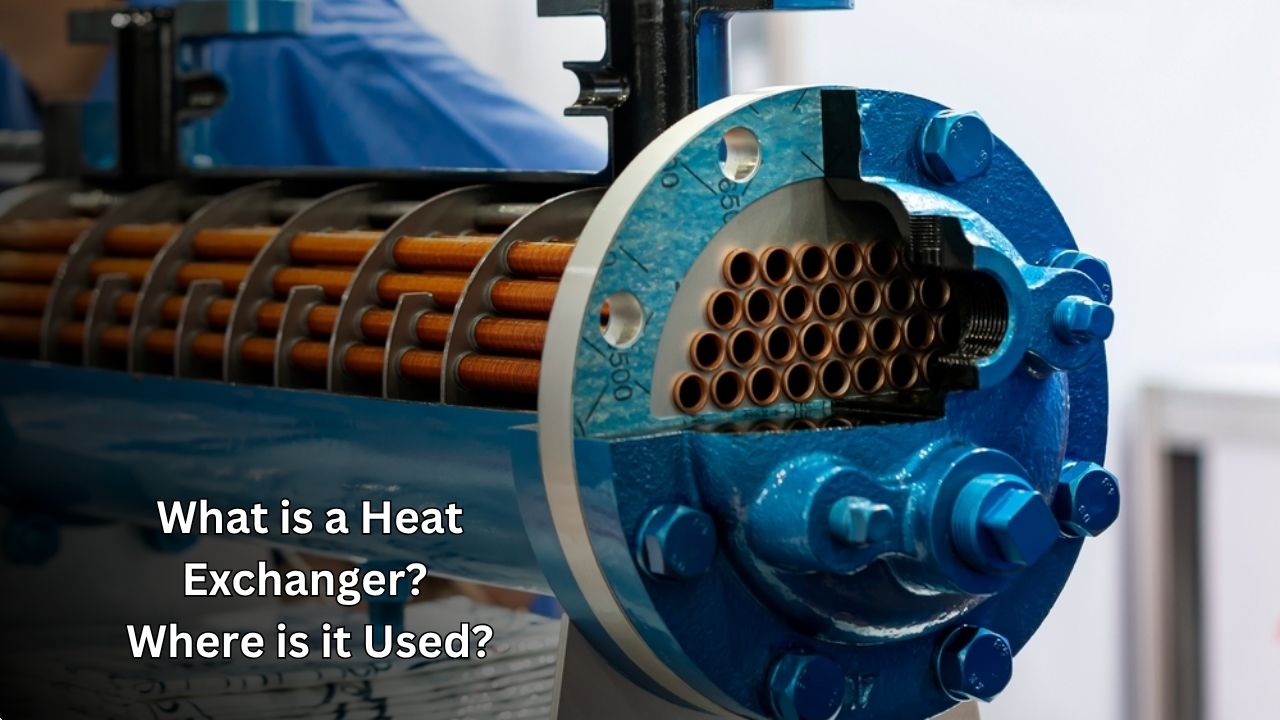

The working principle is based on the fundamental laws of heat transfer. If one fluid is hot, it transfers heat to a cooler fluid. This process typically occurs through a metal surface, as metal conducts heat quickly. Different designs, such as plate, tubular, or shell-and-tube heat exchangers, make this transfer more efficient.

Their applications in industry are extensive. In HVAC systems, heat exchangers save energy in building heating and cooling processes. For example, in an air conditioning unit, they are used to cool or heat air. In the food industry, they are preferred for controlling the temperature of liquids during processes like pasteurization or sterilization.

Energy production is another key application area. In thermal power plants, heat exchangers transfer energy from hot steam in turbines to another fluid, increasing energy efficiency and reducing fuel consumption.

In the chemical industry, heat exchangers play a critical role in temperature control during reaction processes. For instance, they are used in oil refineries to heat or cool crude oil. They also reduce environmental impact by recovering waste heat.

Heat exchangers play a critical role in many industries by providing energy efficiency and temperature control. These devices optimize processes and reduce costs by transferring heat between different fluids.

In the food industry, heat exchangers are widely used. They are essential for pasteurization and sterilization of products like milk, fruit juice, or chocolate. Plate heat exchangers provide fast and effective temperature control, maintaining product quality while offering energy savings.

In the energy sector, heat exchangers are used in thermal power plants to transfer energy from steam to another fluid, increasing electricity production efficiency and reducing fuel consumption. They are also critical components in renewable energy systems, such as geothermal or solar energy plants, for heat transfer.

In the chemical industry, heat exchangers are used for temperature control and waste heat recovery in reaction processes. In oil refineries, tubular heat exchangers are preferred for heating or cooling crude oil, making production processes more efficient and environmentally friendly.

In HVAC systems, heat exchangers are used in building heating and cooling processes. They transfer heat to bring air or water to the desired temperature. Compact designs offer energy savings and space efficiency.

In the maritime sector, heat exchangers are used for cooling ship engines and recovering waste heat, improving fuel efficiency and reducing environmental impact.

Heat exchangers play a critical role in optimizing energy use in industrial and commercial processes, reducing costs by minimizing energy loss.

First, heat recovery is a cornerstone of energy efficiency. Heat exchangers capture waste heat from processes and use it to heat another fluid. For example, in a factory, the energy from hot gases is recovered to heat cold water, reducing additional energy consumption.

High-efficiency designs enhance energy savings. Plate or compact heat exchangers provide effective heat transfer with large surface areas, reducing heating and cooling costs, especially in HVAC systems.

Low-pressure systems also contribute to energy efficiency. In industrial applications, heat exchangers operate with low-pressure fluids to reduce energy consumption. For instance, in the food industry, heat exchangers used during pasteurization minimize energy loss.

Smart control systems optimize heat exchanger performance. IoT-based technologies monitor heat transfer in real-time and adjust energy use based on demand, providing significant savings in energy plants or chemical facilities.

Heat exchangers are devices that transfer heat between different fluids and have a wide range of applications in industry. Various types are designed to meet different needs.

Plate heat exchangers are known for their high efficiency. They transfer heat through thin metal plates and offer space-saving compact designs. They are commonly used in the food industry, such as for milk pasteurization.

Tubular heat exchangers stand out for their robust and durable structures. Heat transfer occurs through nested tubes, making them preferred in oil refineries and chemical plants for high-pressure and high-temperature processes.

Shell-and-tube heat exchangers are used in large-scale applications. Multiple tubes are housed within a shell, and fluids exchange heat through these tubes. They are ideal for steam turbines in power plants.

Air-cooled heat exchangers use air as the cooling medium instead of water, offering advantages in regions with limited water resources. They are commonly seen in thermal power plants or HVAC systems.

Spiral heat exchangers have a compact and efficient design. Spiral channels prevent clogging when working with viscous fluids and are preferred in chemical and wastewater treatment processes.

Heat exchangers provide heat transfer between different fluids, offering energy efficiency and process optimization. These devices play a critical role in cost savings and sustainability across many industries.

In the food industry, heat exchangers are used to maintain product quality. For example, during milk or fruit juice pasteurization, liquids are quickly heated and cooled, ensuring product safety while reducing energy consumption.

In the energy sector, heat exchangers increase efficiency in thermal power plants by recovering waste heat. Transferring heat from steam turbines to another fluid reduces fuel use and environmental impact.

In chemical production, temperature control is essential, and heat exchangers are indispensable. In oil refineries or chemical reactors, they ensure processes are conducted at the correct temperature, maintaining product quality and preventing energy waste.

In HVAC systems, heat exchangers optimize building heating and cooling processes. Compact designs save energy and reduce operating costs. For example, in an air conditioning system, heat exchangers efficiently cool air.

In the maritime and automotive sectors, heat exchangers are used for engine cooling and waste heat recovery, improving fuel efficiency and extending system lifespan.

Heat exchangers provide significant advantages in industrial and commercial processes by enabling heat transfer between different fluids. These devices are critical for efficiency and cost savings.

One of the greatest advantages is energy efficiency. Heat exchangers reduce energy loss by recovering waste heat. For example, in a thermal power plant, steam energy is transferred to another fluid, lowering fuel consumption and operating costs.

Process optimization is another key benefit. In the food industry, heat exchangers enable rapid and precise heating or cooling for processes like pasteurization or sterilization, maintaining product quality while increasing production speed.

Compact designs save space. Plate heat exchangers, in particular, offer high heat transfer efficiency in small spaces, providing a significant advantage in applications with space constraints, such as HVAC systems or ship engines.

Durability and low maintenance are also notable. Modern heat exchangers are made with corrosion-resistant materials, ensuring long-term performance in harsh conditions. For example, stainless steel models used in chemical plants operate without frequent maintenance.

Finally, they offer environmental benefits. Heat exchangers reduce carbon footprints by lowering energy consumption. In wastewater treatment or renewable energy systems, heat recovery supports environmental sustainability.

Fill out the form to discover the most suitable high-end products for your projects. Contact Us Now.