Axial Fan Types Performance and Application Areas

Choosing a resistance manufacturer is a critical step in terms of long-term efficiency, cost, and quality. Although companies may look similar at first glance, there can be significant differences; therefore, a detailed evaluation is essential.

The technical infrastructure and engineering capacity of the manufacturer play a decisive role in producing durable and high-performance resistances. Companies with modern production lines, quality control processes, and R&D investments offer more consistent product quality. Especially in industrial projects, strong engineering infrastructure is a major advantage when dealing with non-standard dimensions or custom design requirements.

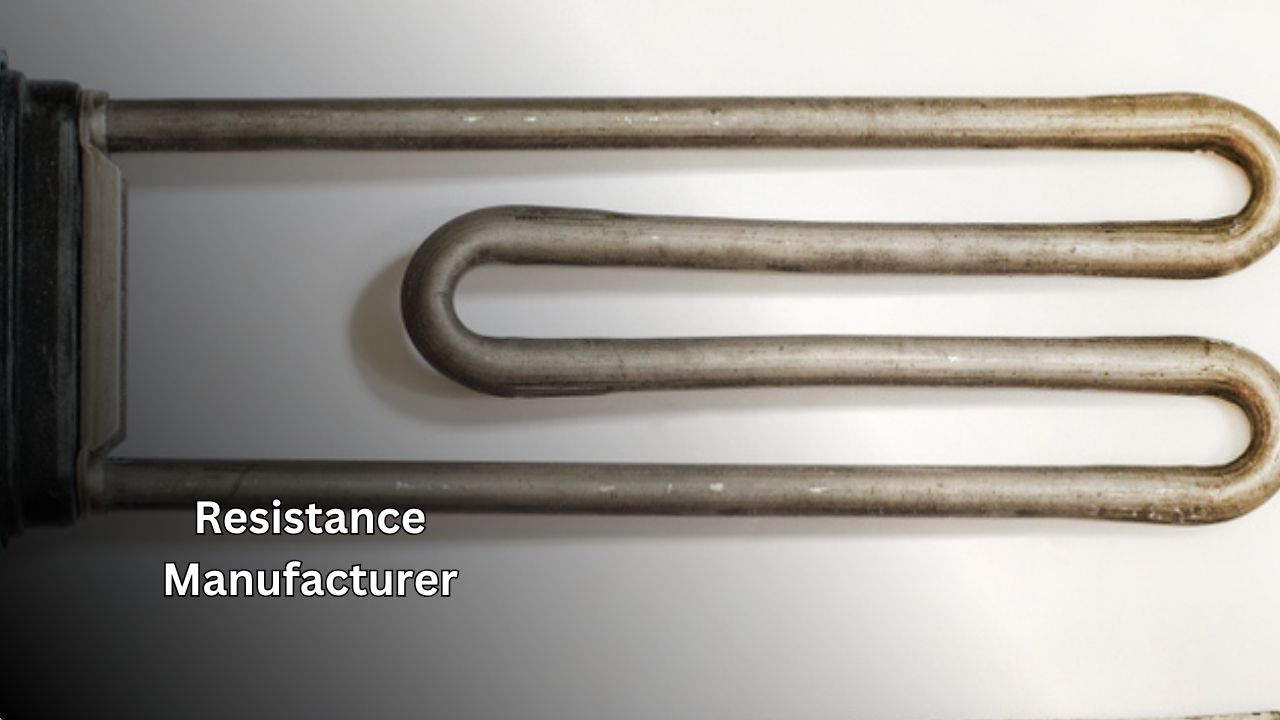

Delivery time and production capacity should also be considered. Manufacturers who can deliver quickly even during busy order periods prevent project delays. Additionally, companies with a wide product range can meet various sector needs. Firms producing different types such as ceramic, tubular, or cartridge resistances offer more flexible solutions.

Certification and compliance with standards are another critical aspect not to overlook. Manufacturers with certificates like ISO 9001, CE, or UL prove themselves in terms of product safety and quality management. These certificates facilitate both legal compliance and export processes.

After-sales support, technical consultancy, and warranty terms also influence the selection. Services such as technical service, maintenance, and spare parts supply provided by the manufacturer reduce operating costs over the long term and minimize failure risks.

Finally, references and customer feedback in the sector give important clues about the manufacturer. Companies that have worked on similar projects, received positive feedback, and established long-term partnerships are generally more reliable choices.

Industrial resistance solutions are critical components that ensure production processes run efficiently and reliably. Resistance manufacturers in this field add value by offering not only standard products but also designs tailored to special projects.

A good resistance manufacturer analyzes customer needs and develops the most suitable product. Products designed considering factors like operating temperature, environmental conditions, and energy efficiency are both long-lasting and reduce maintenance costs. Thus, the manufacturer’s engineering infrastructure and experience are decisive in the selection process.

The manufacturer’s certifications and quality standards also carry vital importance. Certificates like ISO 9001, CE, and UL show that products have passed tests for safety, performance, and legal compliance, reducing risks in both local and export markets.

Another important point is product variety and flexible production capacity. Companies capable of producing different types such as cartridge, tubular, and ceramic resistances offer solutions for a much wider range of sector needs. Also, a manufacturer who provides fast delivery for urgent orders contributes to uninterrupted project progress.

After-sales support and technical consultancy are among the most differentiating factors in long-term collaborations with resistance manufacturers. Quick intervention during faults, maintenance, and spare parts support minimize downtime and prevent production losses. Therefore, attention should be paid not only to product quality but also to the services offered by the manufacturer.

Finding the right resistance manufacturer is a critical step for your project’s success. First, the manufacturer’s product variety and technical capacity should be evaluated. Firms that can produce different resistance types like cartridge, tubular, and ceramic are more likely to meet your custom design needs.

The engineering support from the manufacturer is also an important criterion. Companies that provide not only standard products but also project-based design and prototype development services deliver more accurate solutions in the long term. Strong engineering teams play a critical role, especially if your project has special requirements like high temperature or harsh environmental conditions.

Quality certificates and compliance with international standards must be checked during the selection process. Certificates like ISO 9001, CE, or UL demonstrate the manufacturer’s commitment to product safety and quality management. This provides advantages both in domestic markets and export processes.

The manufacturer’s delivery times and flexible production capacity should not be ignored. A company that can deliver quickly even during busy periods ensures your project continues without interruption. After-sales support, spare parts supply, and technical consultancy services also reduce operating costs in the long term.

References and customer feedback in the sector give the clearest information about the manufacturer’s reliability. A manufacturer with experience in similar projects and positive reviews is a safer choice for your project.

One of the most critical decisions when selecting resistances in industry and manufacturing is whether to go with a local manufacturer or an imported product. Turkey has a developed resistance production ecosystem; this enables local manufacturers to offer serious advantages in price, availability, and technical support. Especially for fast delivery and urgent needs, local manufacturers become more attractive due to stock support.

On the other hand, imported resistances are generally preferred for long-term projects. Advanced technological standards, global quality certificates, and compliance with specific testing processes make imported products stand out. However, cost increases and longer delivery times are risks that must be considered.

When it comes to resistance costs, looking at total cost of ownership is more logical. Not only unit price but also factors like ease of installation, energy efficiency, durability, and service support are decisive in selection. Flexibility gained by working with local manufacturers often provides great advantages in revisions and custom production needs.

Resistance technology is rapidly advancing, and local manufacturers are constantly updating themselves in parallel. Whatever path you choose, analyzing your project’s technical details, long-term goals, and budget carefully will be the smartest way.

Choosing a resistance manufacturer is a far more critical process than it seems; mistakes made can lead to heavy costs in terms of both budget and performance. The first common mistake is focusing solely on price. A resistance that looks cheap may fail quickly, causing greater expenses. It is essential to thoroughly review the warranty terms and technical support services provided by the manufacturer.

Another mistake is skipping reference checks. Who they have worked with before, which projects they participated in, and customer feedback should not be ignored. Lack of documentation or insufficient certification is another common trap. Quality certificates, test reports, and production standards must be reviewed carefully.

Requesting only a “standard product” without sharing project details is also a flawed approach. Every project has specific needs, and the right manufacturer can offer custom solutions accordingly. At this stage, the manufacturer’s engineering support and design experience play a critical role.

Finally, underestimating delivery times is a major risk. Planning without clear information about stock status and production capacity can delay the project. Avoiding these mistakes ensures a productive and smooth process when selecting a resistance manufacturer.

The decision process for resistance manufacturers varies greatly according to your project’s dynamics. The most fundamental distinction is whether you prefer mass production or custom design. For large volume orders, mass production offers cost advantages and standardized quality. Stock management, quick supply, and economies of scale make mass production attractive, especially for companies with continuous production.

However, standard resistances may not be sufficient for some projects; here, custom-designed resistances come into play. Engineering support provided by technical teams during the design phase, detailed analyses, and project-focused solutions increase performance and ensure system compatibility. Critical needs like energy efficiency or harsh operating conditions clearly demonstrate the advantage of custom design.

Regarding cost, custom designs may appear more expensive in the short term, but their durability and easier maintenance can reduce total costs in the long run. Conversely, mass production minimizes initial investment costs and offers financial comfort at the project start.

The most critical factor in this decision process is clearly defining your needs. Do you require high volume and standard products or special engineering solutions? The project scale, application area, and technical expectations play a decisive role in making the right choice.

Fill out the form to discover the most suitable high-end products for your projects. Contact Us Now.