What are Axial Fans? Where are They Used?

For industrial facility managers, unplanned cooling equipment maintenance schedule failures represent a significant threat to production uptime and operational budgets. A proactive industrial cooling maintenance checklist is not merely a preventative measure but a strategic tool for achieving substantial energy efficient cooling systems performance. By systematically addressing key components, businesses can directly slash energy consumption and eliminate the exorbitant costs associated with reactive repairs and halted production lines, turning cooling infrastructure from a cost center into a value driver.

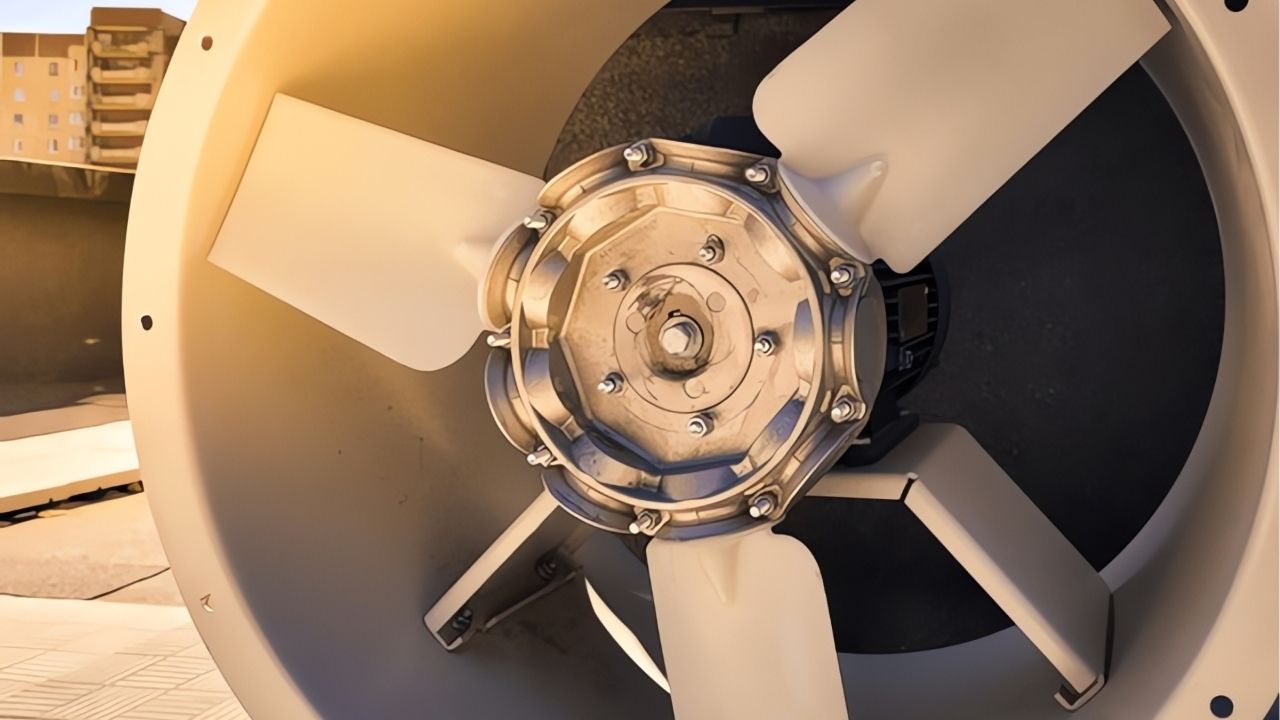

The core of any effective facility cooling solutions strategy lies in the meticulous inspection of critical components like evaporators and condensers. Regular evaporator condenser maintenance, including cleaning coils and checking for refrigerant leaks, ensures optimal heat transfer efficiency, which is fundamental to reducing compressor workload and energy draw. Similarly, a thorough industrial axial fan inspection verifies blade integrity, motor alignment, and bearing condition, safeguarding proper airflow and preventing system overloads that lead to inefficiency and premature failure.

The reliability of this maintenance approach is heavily dependent on the quality of the underlying components. Investing in a durable cooling infrastructure built with precision-engineered parts pays long-term dividends. Manufacturers like Günay Soğutma exemplify this principle, offering both serial and custom cooling production to ensure perfect compatibility with specific operational demands. This disciplined manufacturing focus on high efficiency and durability means components withstand rigorous maintenance cycles and harsh industrial environments, extending service life and protecting the initial investment.

Sector-specific applications further highlight the checklist's value. In the food industry, where temperature control is critical for safety and quality, unwavering food sector cooling reliability is non-negotiable. A disciplined maintenance routine, supported by robust equipment, prevents spoilage and compliance issues. For energy sector operations, maximizing uptime is paramount, and a predictable maintenance schedule minimizes disruption to sensitive processes. In both cases, the synergy between a rigorous checklist and high-performance components creates a resilient operational backbone.

Ultimately, adhering to a comprehensive cooling maintenance checklist is a direct investment in operational excellence and financial performance. The compounded benefits of lower energy bills, reduced spare part costs, and eliminated downtime create a rapid return on investment. By prioritizing a proactive strategy and partnering with experts for reliable components, industrial facilities can transform their cooling systems into models of efficiency and reliability, ensuring continuous production and sustainable cost management for years to come.

A strategic cooling equipment maintenance schedule is the cornerstone of maximizing the lifespan and performance of industrial refrigeration assets. A disciplined industrial cooling maintenance checklist directly translates into enhanced operational efficiency and significant long-term cost avoidance. This proactive approach prevents the gradual degradation of components that silently inflate energy consumption and risk catastrophic failure, ensuring your durable cooling infrastructure delivers on its full potential for years.

The seven-step framework systematically addresses the most critical points of wear and inefficiency. It begins with a comprehensive evaporator condenser maintenance routine, focusing on coil cleanliness and refrigerant pressure checks to maintain peak thermal efficiency. This is complemented by a detailed industrial axial fan inspection to ensure optimal airflow, which is vital for condenser performance and overall system stability. Each step is designed to identify minor issues before they escalate into major repairs, preserving the integrity of the entire system.

The effectiveness of any facility cooling solutions maintenance plan is inherently tied to the quality and suitability of the installed components. Utilizing parts from established manufacturers like Günay Soğutma, which offers both custom cooling production for unique applications and serial production for standard needs, guarantees that replacements and upgrades are engineered for longevity. This synergy between rigorous maintenance and high-caliber parts is what defines truly energy efficient cooling systems, reducing electrical loads and operational expenses.

In critical environments, such as food processing, this checklist is indispensable for achieving uncompromising food sector cooling reliability. A minor temperature deviation can lead to massive product loss, making preventive maintenance a non-negotiable aspect of quality assurance. The checklist provides a clear, actionable protocol for technicians to follow, ensuring consistency and reliability that protects both the product and the production schedule.

Implementing this seven-step periodic maintenance checklist is a direct investment in operational resilience and profitability. The cumulative benefits—extended equipment life, consistently high cooling efficiency, and drastically reduced unplanned downtime—deliver a compelling return on investment. By adhering to a disciplined schedule and specifying components built for endurance, facilities can secure a reliable cooling operation that supports continuous production and sustainable bottom-line results.

A quarterly cooling equipment maintenance schedule provides the ideal rhythm for balancing proactive care with minimal disruption to industrial operations. This structured approach transforms your industrial cooling maintenance checklist into a powerful tool for safeguarding production continuity and enhancing system performance. By addressing potential issues every three months, facilities can prevent the slow accumulation of efficiency losses that lead to higher energy bills and protect the integrity of their entire durable cooling infrastructure.

The guide's core action items focus on components most susceptible to seasonal variations and operational wear. A thorough quarterly evaporator condenser maintenance inspection, including cleaning and verifying refrigerant levels, is essential for maintaining consistent heat exchange rates. This must be paired with a diligent industrial axial fan inspection to confirm blade balance and motor performance, as even minor airflow reductions force compressors to work harder, degrading overall efficiency. These focused checks are the foundation of reliable facility cooling solutions.

Executing this guide effectively relies on the inherent quality and precision of the system's components. Specifying parts from manufacturers with a reputation for disciplined engineering, such as Günay Soğutma, ensures that each maintenance cycle reinforces system longevity. The availability of both standard and custom cooling production means that every replacement or upgrade is a perfect fit, contributing directly to the goal of achieving energy efficient cooling systems with predictable performance.

This quarterly discipline is particularly critical for applications demanding absolute food sector cooling reliability. In food processing and storage, a consistent thermal environment is paramount for safety and quality compliance. A quarterly inspection cadence catches potential problems well before they can impact product temperature, thereby protecting both inventory and brand reputation from the costly consequences of a cooling failure during a critical production run.

Adopting this quarterly industrial cooling maintenance guide is a decisive step toward operational excellence and cost management. The regular, minor investments in inspection and upkeep yield substantial returns through extended asset life, optimized energy consumption, and the near-elimination of production-stopping emergencies. By integrating this disciplined schedule with high-performance components, industrial managers can ensure their cooling systems operate as a reliable, efficient asset rather than a vulnerable liability.

The fundamental choice between proactive and reactive maintenance strategies directly dictates the financial and operational performance of any industrial cooling system. A proactive cooling equipment maintenance schedule, guided by a precise industrial cooling maintenance checklist, invests in predictability and prevention. In contrast, a reactive approach incurs significantly higher costs through emergency repairs, production stoppages, and the accelerated degradation of components, ultimately compromising the durable cooling infrastructure that facilities depend on.

The comparative checklist highlights stark differences in practice and outcome. A proactive strategy mandates regular evaporator condenser maintenance to sustain heat transfer efficiency and a scheduled industrial axial fan inspection to ensure optimal airflow, both critical for maintaining energy efficient cooling systems. Reactive maintenance, however, addresses these components only after a failure occurs, often resulting in secondary damage, inefficient operation leading to higher energy bills, and costly unscheduled downtime that disrupts the entire production line.

The viability of a proactive model is intrinsically linked to the quality and resilience of the installed components. High-performance parts, such as those engineered through the disciplined custom cooling production and serial processes of manufacturers like Günay Soğutma, are designed to withstand the rigors of continuous operation. This inherent durability makes them ideal for a preventive maintenance regime, as they respond well to regular inspection and minor adjustments, forming the backbone of reliable facility cooling solutions.

For sectors where failure is not an option, such as food processing, the proactive approach is essential for guaranteeing food sector cooling reliability. A reactive stance here poses an unacceptable risk of product spoilage and safety compliance breaches. The comparative checklist provides a clear economic argument, demonstrating that the planned, smaller investments in proactive upkeep are vastly outweighed by the potential losses from a single cooling system failure during a critical production cycle.

Ultimately, adopting a proactive maintenance philosophy with a rigorous comparative checklist is a strategic decision that maximizes return on investment and system longevity. The cumulative savings from avoided emergencies, reduced energy consumption, and extended equipment life create a compelling financial advantage. By committing to a proactive schedule and specifying components built for endurance, industrial operators secure not just cooling performance, but the overall reliability and profitability of their production operations.

A generic cooling equipment maintenance schedule often leads to either over-maintenance, wasting resources, or under-maintenance, inviting failure. A meticulously tailored industrial cooling maintenance checklist, however, aligns precisely with your operational profile, enabling savings of up to 30 percent on operational expenses. This optimization is achieved by focusing resources where they are most needed, preventing energy waste, and extending the service life of your durable cooling infrastructure through intelligent, data-driven interventions.

The custom schedule targets specific components based on their actual duty cycles and environmental exposure. For instance, a facility in a dusty environment would require more frequent evaporator condenser maintenance to preserve coil efficiency, while a high-utilization site would prioritize industrial axial fan inspection intervals to prevent airflow-related compressor strain. This precision ensures that every maintenance action contributes directly to sustaining energy efficient cooling systems, eliminating unnecessary labor and parts costs associated with a one-size-fits-all approach.

The philosophy of customization extends beyond the maintenance plan to the components themselves. Just as a tailored checklist optimizes upkeep, utilizing custom cooling production from experienced manufacturers like Günay Soğutma ensures that the hardware is perfectly suited to the application's demands. This synergy between a custom maintenance regimen and purpose-built equipment creates the most resilient and cost-effective facility cooling solutions, where each element is engineered for maximum longevity and minimal lifetime cost.

This tailored approach is particularly impactful for ensuring food sector cooling reliability, where regulatory requirements and batch processing schedules impose unique demands. A custom schedule can be designed around production cycles, performing critical inspections during planned downtimes to absolutely avoid interference with sensitive operations. This level of planning prevents the catastrophic expenses of spoilage and compliance fines, securing the operational budget.

Implementing a custom maintenance schedule is a strategic move that translates precise planning into tangible financial returns. The projected 30 percent reduction in operational expenses is realized through a combination of lowered energy consumption, deferred capital expenditures on replacements, and the elimination of costly emergency repairs. By embracing a customized strategy for both maintenance and component specification, industrial facilities can transform their cooling systems from a fixed cost into a variable and highly optimized investment.

The pre-season inspection is a critical event in any cooling equipment maintenance schedule, serving as the definitive preparation for periods of high demand. This focused industrial cooling maintenance checklist is designed to verify system integrity and optimize performance before operational loads intensify. By proactively identifying and rectifying issues, facilities can guarantee uninterrupted production cycles and ensure their durable cooling infrastructure operates at peak efficiency when it is needed most, preventing costly downtime during critical periods.

The checklist prioritizes components that are most vulnerable to seasonal stress and wear. A comprehensive evaporator condenser maintenance procedure, including a thorough cleaning and pressure test, is essential to restore maximum heat rejection capacity ahead of rising ambient temperatures. Simultaneously, a pre-season industrial axial fan inspection confirms blade integrity, motor amperage, and bearing condition to保障unimpeded airflow, which is foundational for maintaining energy efficient cooling systems under full load.

The reliability of this pre-season preparation is heavily dependent on the quality of the installed components. Utilizing parts engineered for resilience, such as those produced through the disciplined custom cooling production processes of manufacturers like Günay Soğutma, ensures that the system can withstand the rigorous demands of a full season. This alignment between robust hardware and a meticulous pre-start checklist forms the core of dependable facility cooling solutions that deliver consistent performance.

In industries where temperature control is synonymous with product viability, such as ensuring food sector cooling reliability, the pre-season checklist is non-negotiable. A failure during a peak production run can lead to massive spoilage and compliance issues. Conducting these verifications beforehand provides absolute confidence that the cooling system will perform flawlessly, protecting both product quality and profitability throughout the busiest operational windows.

Executing a thorough pre-season cooling equipment checklist is a direct investment in operational security and financial performance. The minimal time and resource investment required for the inspection pale in comparison to the potential losses from an unexpected breakdown during high-demand periods. By adopting this disciplined pre-season practice and specifying high-quality components, facilities secure a foundation of reliability that supports uninterrupted production, optimal efficiency, and long-term operational savings.

A rigorous cooling equipment maintenance schedule focused on specific critical checks is the primary driver for achieving both operational sustainability and long-term system reliability. Integrating these non-negotiable items into your standard industrial cooling maintenance checklist directly translates into reduced environmental impact and enhanced asset longevity. This approach ensures that the durable cooling infrastructure operates not just efficiently today, but continues to do so for years, minimizing waste and maximizing the return on investment through a disciplined, forward-thinking maintenance philosophy.

The five critical checks target the most influential factors on system performance and resource consumption. The foremost is a detailed evaporator condenser maintenance inspection, ensuring coils are free of debris and fouling that force compressors to consume excess energy. This is paired with a meticulous industrial axial fan inspection to verify aerodynamic efficiency, as even minor imbalances can lead to significant power draws. These actions are fundamental to maintaining truly energy efficient cooling systems that align with sustainability goals by reducing electricity usage and carbon footprint.

The effectiveness of these critical checks is amplified when performed on components designed for endurance. Specifying parts from manufacturers committed to engineering excellence, such as Günay Soğutma, guarantees that the system can consistently meet the demands of a sustainability-focused cooling equipment maintenance schedule. Their capability in both standard and custom cooling production ensures that every component within the durable cooling infrastructure contributes to long-term reliability and efficiency.

For mission-critical applications, these checks are vital for ensuring uncompromising food sector cooling reliability, where sustainability also means guaranteeing product safety and minimizing waste from temperature deviations. A reliable cooling system, maintained through these critical procedures, prevents spoilage and supports a circular economy model by extending equipment life and reducing the need for raw materials for replacements. This makes the checklist an integral part of any modern facility cooling solutions strategy.

Prioritizing these critical checks within your maintenance routine is an investment in future-proofing your operations. The synergy between preventive care and high-quality components creates a virtuous cycle of efficiency and durability. This disciplined approach not only secures immediate energy savings but also builds a durable cooling infrastructure capable of delivering sustainable, reliable performance for its entire lifecycle, protecting both your production output and your bottom line.

For facility managers, the primary objective of a structured cooling equipment maintenance schedule is to transform cooling system upkeep from a source of unpredictable expenses into a lever for controlled cost savings and reliability. This essential guide centers on a disciplined industrial cooling maintenance checklist that systematically minimizes repair frequency and maximizes energy efficiency. By adhering to this proactive framework, managers can directly protect their operational budget while ensuring the long-term integrity of their durable cooling infrastructure.

The guide's structure focuses inspection efforts on components with the highest impact on performance and energy consumption. A cornerstone of this approach is rigorous evaporator condenser maintenance, which maintains optimal heat exchange efficiency and prevents the compressor overload that leads to excessive power use. This must be consistently paired with a comprehensive industrial axial fan inspection to ensure unimpeded airflow, a critical factor for sustaining energy efficient cooling systems and avoiding the cascading failures that necessitate major repairs.

The success of this structured upkeep is fundamentally dependent on the quality of the system's components. Implementing a checklist with inferior parts yields diminishing returns. This is why specifying equipment from manufacturers with a legacy of disciplined engineering, such as Günay Soğutma, is a strategic decision. Their expertise in both serial and custom cooling production ensures that every replacement or upgrade seamlessly integrates into the existing facility cooling solutions, enhancing overall system resilience and responsiveness to maintenance.

In environments demanding absolute precision, such as those requiring food sector cooling reliability, this managerial guide is indispensable. The structured checklist provides a clear, actionable protocol that technicians can follow to verify system readiness, preventing temperature fluctuations that could compromise product safety. This level of controlled, predictable upkeep is far more cost-effective than the emergency responses required after a system failure disrupts a production run.

Ultimately, this facility manager's guide provides a blueprint for achieving total cost of ownership optimization. The disciplined application of a structured checklist, combined with investment in high-quality components, creates a virtuous cycle of performance. This strategy not only delivers immediate energy savings and reduced repair costs but also solidifies the foundation for a cooling system that supports uninterrupted, efficient production for its entire operational lifespan.

Fill out the form to discover the most suitable high-end products for your projects. Contact Us Now.