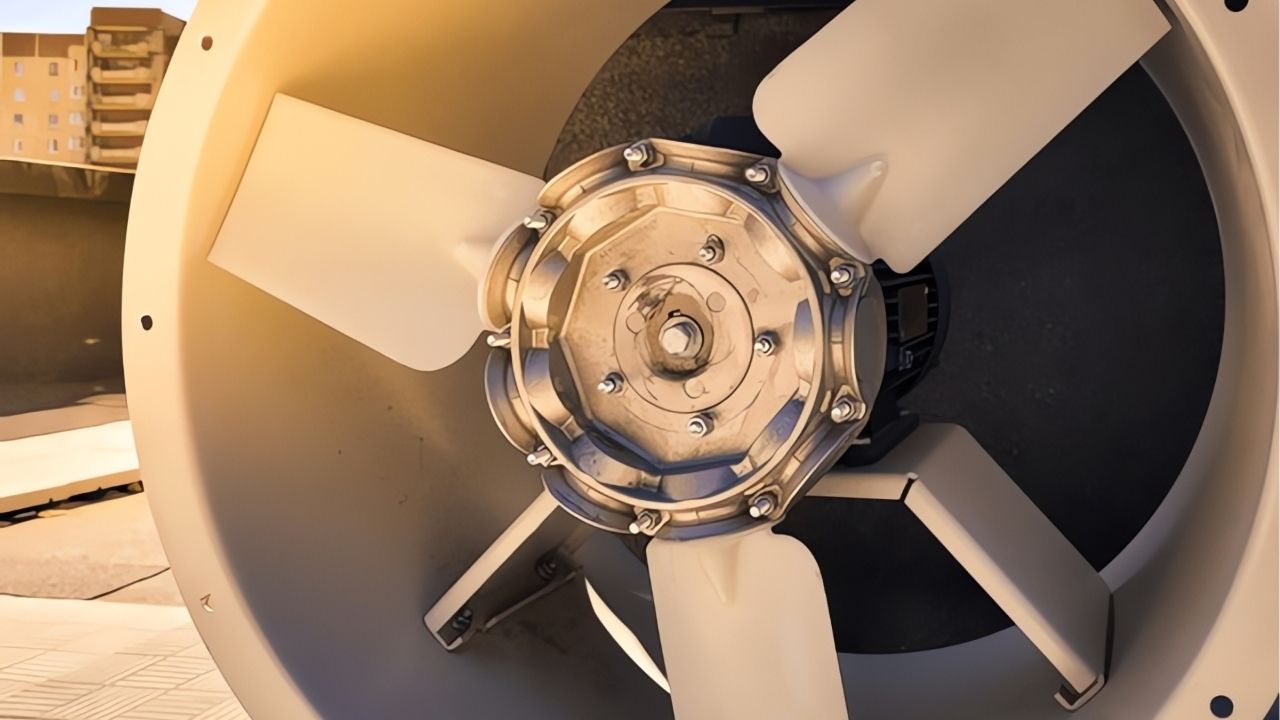

What are Axial Fans? Where are They Used?

Evaluating the true industrial condenser price requires a shift in perspective from initial purchase cost to total lifetime value, particularly when investing in high-efficiency industrial cooling solutions. The superior performance of an energy-optimized condenser directly translates into measurable long-term ROI through drastically reduced electrical consumption and enhanced system stability. Securing a detailed energy saving condenser quote is therefore the first step in quantifying these operational savings and understanding how a higher-quality component pays for itself over its service life.

The engineering behind a high-efficiency condenser focuses on maximizing heat transfer while minimizing pressure drop and fan power requirements. This is a core strength of Günay Soğutma condenser production, where advanced coil designs and materials are used to achieve optimal thermal performance. When paired with a correctly specified custom axial fan, the system operates at its peak efficiency curve, reducing the energy draw of the entire refrigeration circuit. This synergy is critical for building a reliable cooling infrastructure that can withstand continuous operation in food processing or energy generation environments.

This focus on durability also significantly impacts the perceived durable condenser cost. A condenser built with robust materials and corrosion-resistant coatings will have a longer operational lifespan, delaying capital replacement expenses. Furthermore, a well-designed unit simplifies evaporator condenser maintenance routines, with features like accessible cleaning ports and resilient fin stacks that reduce downtime and labor costs. This engineered reliability ensures that the system contributes to production uptime rather than posing a risk of failure.

Ultimately, the most accurate assessment of cost comes from a project-specific quotation that accounts for your facility's unique load profile, ambient conditions, and efficiency goals. This tailored analysis reveals the direct link between the initial investment in a high-performance condenser and the cumulative financial benefits of lower utility bills, reduced maintenance, and uninterrupted production. Requesting a comprehensive quote is not merely a pricing exercise but a strategic planning tool for achieving a cooler, more efficient, and more profitable operation.

The true industrial condenser price extends far beyond the initial invoice, encompassing a complex equation of energy consumption, maintenance frequency, and operational reliability over the unit's entire lifecycle. For facility managers focused on high-efficiency industrial cooling, understanding this total cost of ownership is essential for making capital decisions that yield substantial operational savings. A comprehensive view reveals that the most economical condenser is often the one with superior engineering that minimizes ongoing expenses.

Energy efficiency is the most significant variable in this calculation. A condenser designed for optimal heat rejection allows compressors to operate at lower head pressures, drastically reducing power draw. This performance is a benchmark of Günay Soğutma condenser production, where precision engineering ensures maximum thermal transfer with minimal energy input. Integrating such a unit with a perfectly matched custom axial fan creates a synergistic effect, further enhancing efficiency and solidifying the foundation of a reliable cooling infrastructure.

Durability is another critical cost factor. The durable condenser cost is justified by its extended service life and resistance to harsh industrial environments, which defers replacement capital. Robust construction also simplifies evaporator condenser maintenance, requiring less frequent cleaning and reducing the risk of unscheduled downtime that halts production. Obtaining an energy saving condenser quote that details these long-term benefits provides a transparent view of the investment's value.

Ultimately, the most strategic approach to condenser procurement is to evaluate specifications through the lens of lifetime performance. The marginally higher initial cost of a high-efficiency, durable model is consistently offset by years of lower electricity bills, reduced maintenance labor, and unwavering cooling capacity that protects production output. By prioritizing engineering excellence over short-term price, industrial operations can secure not just a component, but a pillar of sustainable and cost-effective facility management.

Accurately projecting your industrial condenser price and potential energy savings requires a detailed analysis of several technical and operational factors unique to your facility. These variables directly influence the initial investment and the long-term financial return, making a customized energy saving condenser quote an indispensable tool for strategic planning. Understanding these determinants allows managers to make informed decisions that balance upfront cost with lifecycle performance for high-efficiency industrial cooling.

The primary cost drivers include thermal capacity, materials of construction, and design complexity. A condenser for a large food processing plant will have a different specification and durable condenser cost compared to one for a compact energy sector application. The selection of materials, such as corrosion-resistant coatings for harsh environments, is a critical factor in longevity and a key aspect of Günay Soğutma condenser production. Furthermore, the integration with a custom axial fan optimized for specific static pressure and airflow requirements adds another layer of performance and cost consideration.

Energy savings are predominantly determined by the condenser's heat transfer efficiency and the associated reduction in compressor workload. A highly efficient unit lowers the system's head pressure, which is the largest contributor to energy consumption. This efficiency is not just about the condenser itself but its role within the entire reliable cooling infrastructure. Ease of access for cleaning and inspection also plays a major role in sustained efficiency, impacting long-term evaporator condenser maintenance costs and preventing gradual performance degradation.

Given these interdependencies, the most accurate assessment comes from providing a manufacturer with specific operational data cooling load, ambient conditions, desired refrigerant, and runtime. This enables the creation of a solution precisely engineered for your facility's needs, ensuring that every aspect of the industrial condenser price is justified by a corresponding gain in efficiency, durability, and operational reliability. Requesting a detailed quote based on these factors is the first step toward a optimized, cost-effective cooling system.

Evaluating high-efficiency condenser pricing necessitates a rigorous ROI calculation that accounts for both immediate energy reduction and long-term maintenance savings. The premium associated with a superior unit is not an expense but a strategic investment, with payback periods often dramatically shortened by continuous operational benefits. Securing a detailed energy saving condenser quote that includes projected performance data is essential for validating this investment against baseline industrial condenser price models and justifying the capital allocation.

The most substantial ROI component is energy reduction. A high-efficiency condenser lowers system head pressure, which directly decreases compressor power consumption. This core principle of high-efficiency industrial cooling is engineered into products through advanced thermal designs, such as those utilized in Günay Soğutma condenser production. When this condenser is paired with a custom axial fan calibrated for optimal airflow, the synergistic effect can reduce total system energy use by significant percentages, creating a predictable and recurring financial return.

Maintenance savings constitute the second critical variable in the ROI equation. The durable condenser cost is offset by a longer service interval and reduced susceptibility to failure. Features like corrosion-resistant materials and accessible coil designs simplify evaporator condenser maintenance, cutting labor hours and chemical costs while maximizing production uptime. This durability is a cornerstone of a reliable cooling infrastructure, preventing costly emergency repairs and production stoppages.

The calculation is straightforward sum the annual energy savings and reduced maintenance costs, then divide by the initial investment premium over a standard unit. This exercise consistently demonstrates that the higher initial industrial condenser price for an efficient model is quickly amortized. By focusing on total cost of ownership rather than purchase price alone, facility managers can make data-driven decisions that enhance operational profitability and secure a cooling system built for long-term, cost-effective performance.

The decision between a standard and custom condenser involves a critical price comparison that must evaluate long-term energy savings against the initial industrial condenser price. While a standard unit may appear cost-effective upfront, a custom solution engineered for your specific production line often delivers superior efficiency and a faster return on investment. The key is to assess which option provides the optimal balance for your unique operational demands and contributes to a reliable cooling infrastructure.

Standard condensers are designed for broad applications with common load and ambient conditions. They offer a lower entry point but may operate suboptimally if your facility has unique challenges, such as high ambient temperatures or variable loads. This can lead to higher energy consumption as the system compensates for the mismatch. In contrast, a custom condenser, like those available through Günay Soğutma condenser production, is precisely sized and configured. It ensures high-efficiency industrial cooling by perfectly matching the thermal load, which minimizes compressor work and maximizes energy savings from day one.

The integration of ancillary components further illustrates the value of customization. A standard condenser paired with a generic fan may suffer from airflow inefficiencies. However, a custom design can incorporate a perfectly matched custom axial fan, creating a synergistic system that operates at peak efficiency. This precision engineering also impacts long-term costs; a bespoke unit often has a higher durable condenser cost upfront but significantly reduces evaporator condenser maintenance and extends the equipment's service life.

Ultimately, the most accurate assessment comes from a project-specific energy saving condenser quote that compares both options side-by-side. This analysis will quantify the energy savings of a custom fit against the lower initial cost of a standard model. For most modern production lines where cooling is critical, the long-term financial and operational benefits of a tailored solution consistently outweigh the short-term savings of a generic unit, making it the superior investment for sustained profitability and performance.

Requesting a detailed quote for a durable condenser is the most effective way to visualize how a higher initial industrial condenser price converts into substantial long-term savings on energy and maintenance. This financial translation is critical for justifying capital expenditure in high-efficiency industrial cooling components, moving the focus from simple procurement to strategic investment in operational reliability. An energy saving condenser quote provides the concrete data needed to forecast ROI and understand the true value of engineering excellence.

The premium associated with a durable unit directly purchases enhanced performance characteristics. This includes superior materials that resist corrosion, advanced coil designs that maximize heat transfer, and construction that withstands industrial stresses. These features are central to Günay Soğutma condenser production, ensuring each unit contributes to a reliable cooling infrastructure. When this condenser is integrated with a custom axial fan, the system operates at optimal efficiency, reducing the compressor's energy load and delivering immediate cost savings on electricity.

The long-term financial benefits are twofold. First, the reduced energy consumption becomes a permanent line-item saving. Second, the robust construction drastically lowers lifetime evaporator condenser maintenance costs. Fewer cleanings, reduced risk of leaks, and extended service intervals minimize both planned and unplanned downtime, protecting production schedules. This makes the durable condenser cost a proactive investment in uptime and predictability.

Therefore, the act of obtaining a quote is not a passive inquiry but an active step in financial planning for your facility's cooling needs. It quantifies the direct correlation between quality engineering and operational economics. By analyzing a comprehensive quote, managers can confidently invest in a condenser that delivers not just cooling capacity, but also measurable financial returns through lower operating expenses and unwavering reliability for years to come.

Optimizing condenser investment requires a strategic approach that balances the initial industrial condenser price against guaranteed gains in energy efficiency and long-term performance. This process begins with a clear understanding that the lowest purchase price often leads to the highest total cost of ownership, while a strategically selected unit becomes a profit center through operational savings. The key is to utilize tools like an energy saving condenser quote to make data-driven decisions that enhance your facility's reliable cooling infrastructure.

The first step is accurate sizing and specification. A condenser that is either oversized or undersized for the application will operate inefficiently, increasing energy consumption and wear. This precision is a fundamental aspect of Günay Soğutma condenser production, where engineering discipline ensures perfect alignment with thermal loads. For maximum high-efficiency industrial cooling, the condenser must be viewed as part of a system, ideally paired with a custom axial fan to create a perfectly balanced heat rejection unit that minimizes total power draw.

Next, evaluate the durable condenser cost in the context of lifecycle expenses. Investing in robust materials and corrosion protection may increase the upfront price but dramatically reduces future evaporator condenser maintenance costs and frequency. This durability directly translates to higher uptime and predictability, as the risk of unscheduled repairs is minimized. A well-built condenser maintains its efficiency over a longer period, ensuring that the investment continues to pay dividends year after year without degradation.

Ultimately, optimization is achieved by selecting a condenser that offers the best performance per unit of lifetime cost. This means prioritizing engineering quality, efficiency certifications, and compatibility with your specific operational environment. By following this how-to guide, facility managers can transform their condenser procurement from a simple replacement task into a strategic upgrade that delivers lower energy bills, reduced maintenance, and superior cooling performance that reliably supports production goals.

Fill out the form to discover the most suitable high-end products for your projects. Contact Us Now.