What are Axial Fans? Where are They Used?

Implementing targeted cooling efficiency strategies is essential for industrial facilities seeking to reduce operational expenses while maintaining production reliability. These approaches go beyond basic maintenance to optimize the entire thermal management system, delivering significant industrial energy savings without compromising performance. By focusing on system-wide improvements, businesses can transform their cooling infrastructure from a cost center into a strategic asset that supports both profitability and sustainability goals within their durable cooling infrastructure.

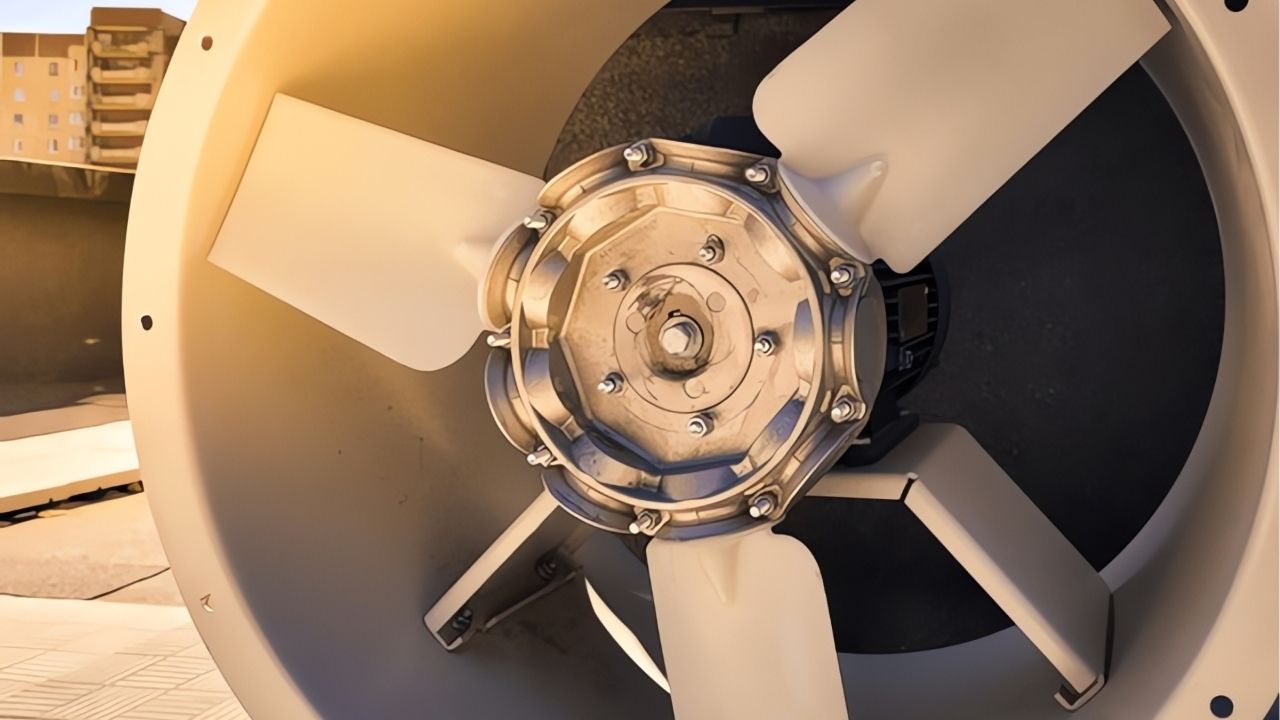

The most impactful strategies address core components where efficiency gains yield the greatest returns. Optimizing evaporator condenser efficiency through regular cleaning and proper refrigerant charge management can reduce compressor workload by up to 25 percent. Complementing this with industrial axial fan optimization ensures optimal airflow with minimal energy consumption, directly enhancing the performance of energy efficient cooling systems. These technical adjustments, when systematically applied, create a compounding effect that dramatically lowers electricity consumption while extending equipment service life.

For facilities with unique operational requirements, custom cooling production offers a pathway to precision efficiency. Tailored components designed for specific load profiles and environmental conditions eliminate the performance compromises of standard equipment. Manufacturers with engineering excellence, such as Günay Soğutma, specialize in creating these optimized solutions that form the foundation of advanced facility cooling solutions. This approach is particularly valuable for food sector cooling applications where temperature precision directly impacts product quality and safety.

The financial benefits of these efficiency strategies extend far beyond reduced utility bills. Lower operating temperatures and balanced system pressures reduce mechanical stress on all components, decreasing maintenance frequency and preventing costly unplanned downtime. This proactive approach to energy management ensures that cooling systems operate at peak performance throughout their lifecycle, protecting the substantial capital investment in industrial refrigeration equipment while supporting continuous production operations.

Achieving a 30 percent reduction in operational expenses through cooling efficiency requires a systematic implementation of proven cooling efficiency strategies rather than isolated quick fixes. This significant industrial energy savings target is attainable by addressing the entire thermal management system comprehensively, from component performance to operational protocols. The implementation begins with a thorough audit of current energy consumption patterns and identification of the most impactful improvement opportunities within your durable cooling infrastructure.

The core implementation focuses on optimizing key components that drive energy consumption. This includes scheduled maintenance to maximize evaporator condenser efficiency through coil cleaning and refrigerant optimization, which directly reduces compressor workload. Simultaneously, implementing industrial axial fan optimization through variable speed drives and regular blade maintenance ensures airflow matches exact requirements without excess energy use. For facilities with specialized needs, custom cooling production from experienced manufacturers like Günay Soğutma provides components precisely engineered for peak performance in specific applications.

Sector-specific implementations yield particularly strong results. For food sector cooling operations, strategies might include optimizing defrost cycles and implementing heat recovery systems that repurpose waste energy. These targeted approaches, when integrated into comprehensive facility cooling solutions, compound their effectiveness. The transition to truly energy efficient cooling systems often involves upgrading control systems to enable smart scheduling and load matching, preventing energy waste during partial-load conditions.

The successful implementation of these strategies creates a virtuous cycle of efficiency and savings. As energy consumption decreases, mechanical stress on components reduces, extending equipment life and further lowering maintenance costs. This systematic approach not only achieves the immediate 30 percent operational expense reduction but also establishes a foundation for sustained efficiency gains throughout the equipment lifecycle, protecting your production capability while delivering substantial financial returns on your cooling infrastructure investment.

Maximizing return on investment in industrial cooling requires implementing a comprehensive set of cooling efficiency strategies that address both equipment performance and operational practices. This technical guide outlines ten proven approaches that collectively optimize industrial energy savings while enhancing system reliability. The strategic implementation of these methods transforms cooling infrastructure from a capital expense into a value-generating asset, delivering measurable financial returns through reduced operational costs and extended equipment lifespan within your durable cooling infrastructure.

The foundation of maximizing ROI begins with component-level optimization. Strategy one focuses on achieving peak evaporator condenser efficiency through regular cleaning and proper refrigerant management, which can reduce compressor energy consumption by 20-30 percent. Strategy two implements industrial axial fan optimization with variable frequency drives to match airflow precisely to cooling demand. For facilities requiring specialized solutions, strategy three leverages custom cooling production capabilities from manufacturers like Günay Soğutma to create components specifically engineered for maximum efficiency in unique operating conditions.

Sector-specific applications demonstrate the ROI potential of these strategies. In food sector cooling operations, strategies like optimizing defrost cycles and implementing heat recovery systems can dramatically reduce energy waste while maintaining critical temperature control. These technical approaches, when integrated into holistic facility cooling solutions, create synergistic effects that compound their individual benefits. The transition to fully energy efficient cooling systems involves advanced control strategies that automatically adjust operation based on real-time load requirements, preventing energy expenditure during unnecessary full-capacity operation.

The cumulative impact of these ten strategies delivers a substantially enhanced cooling ROI through multiple channels. Beyond direct energy cost reduction, the improved operating conditions reduce mechanical stress on all system components, decreasing maintenance frequency and preventing costly production interruptions. This comprehensive approach ensures that every aspect of the cooling system contributes to operational efficiency, protecting your capital investment while delivering continuous financial returns through optimized performance and reliability.

Advancing beyond routine maintenance requires implementing sophisticated cooling efficiency strategies that proactively enhance performance and extend system life. These ten advanced approaches move past reactive repairs to optimize the entire thermal management ecosystem, delivering substantial industrial energy savings while building a more resilient durable cooling infrastructure. This evolution from basic upkeep to strategic optimization represents the difference between merely operating equipment and maximizing its value throughout its operational lifecycle.

The first tier of advanced strategies involves precision component optimization. This includes implementing real-time monitoring for evaporator condenser efficiency to maintain ideal heat transfer coefficients under varying load conditions. Advanced industrial axial fan optimization incorporates aerodynamic profiling and smart controls that respond dynamically to ambient conditions. For operations with unique thermal profiles, pursuing custom cooling production through engineering partners like Günay Soğutma ensures components are precisely matched to specific operational demands, creating truly energy efficient cooling systems from the ground up.

Sector-specific advanced strategies deliver particularly significant benefits. In food sector cooling applications, strategies might include predictive defrost algorithms based on actual frost accumulation rather than timers, and thermal energy storage systems that shift cooling loads to off-peak hours. These advanced techniques, when integrated into comprehensive facility cooling solutions, achieve efficiency levels unattainable through basic maintenance alone. The implementation of system-level digital twins allows for continuous optimization without physical intervention, representing the cutting edge of cooling management.

Adopting these advanced strategies transforms cooling systems into intelligent assets that actively contribute to operational excellence. The resulting improvements in efficiency reduce mechanical stress on all components, effectively extending their service life while minimizing the frequency and cost of interventions. This proactive approach to cooling management not only delivers immediate energy and maintenance savings but also establishes a foundation for sustained performance excellence, ensuring your cooling infrastructure remains a reliable, cost-effective asset for its entire operational lifespan.

This blueprint provides facility managers with a structured approach to implementing cooling efficiency strategies that deliver sustainable cost reduction while maintaining operational reliability. The ten-strategy framework addresses both immediate energy consumption and long-term capital preservation, creating a pathway to significant industrial energy savings without compromising production capabilities. By systematically applying these methods, managers can transform their cooling operations from a cost center into an optimized component of their durable cooling infrastructure that contributes directly to bottom-line performance.

The blueprint's core strategies focus on optimizing component performance and system integration. Strategy one establishes a predictive maintenance program for maximizing evaporator condenser efficiency through scheduled cleaning and performance monitoring. Strategy two implements comprehensive industrial axial fan optimization with smart controls that adjust operation based on real-time cooling demand. For facilities with unique requirements, strategy three leverages custom cooling production expertise from manufacturers like Günay Soğutma to create purpose-built components that form the foundation of truly energy efficient cooling systems.

Sector-specific applications of this blueprint yield particularly strong results. In food sector cooling operations, strategies include implementing heat recovery systems and optimizing defrost cycles based on actual usage patterns rather than fixed schedules. These specialized approaches, when integrated into holistic facility cooling solutions, address the unique challenges of temperature-sensitive operations while maximizing energy efficiency. The blueprint also incorporates advanced control strategies that automatically balance cooling capacity with production demands, preventing energy waste during partial-load conditions.

Implementing this comprehensive blueprint establishes a foundation for continuous improvement in cooling efficiency and cost management. The synergistic effect of these strategies reduces energy consumption while simultaneously extending equipment lifespan through optimized operating conditions. This proactive approach to cooling management not only achieves immediate cost reductions but also creates a more resilient thermal management system capable of supporting production goals reliably for years to come, ensuring sustainable operational excellence.

Data-driven cooling efficiency strategies represent the evolution from scheduled maintenance to predictive optimization, using operational intelligence to achieve unprecedented industrial energy savings and reliability. By implementing comprehensive monitoring and analytics, facilities can transition from reactive responses to proactive management of their durable cooling infrastructure. This approach leverages real-time performance data to identify inefficiencies, predict maintenance needs, and optimize system operation continuously, ensuring cooling systems support rather than constrain production objectives.

The implementation begins with installing sensors that monitor key performance indicators across critical components. Continuous tracking of evaporator condenser efficiency parameters like approach temperature and pressure differentials allows for precise maintenance scheduling before efficiency degrades. Similarly, data-driven industrial axial fan optimization uses vibration analysis and power consumption patterns to optimize speed settings and predict bearing failures. For components requiring specialized performance, custom cooling production from manufacturers like Günay Soğutma can incorporate embedded sensors during manufacturing, creating intelligent components designed for data-rich operation within advanced facility cooling solutions.

Sector-specific data applications deliver particularly valuable insights. In food sector cooling operations, data analytics can correlate energy consumption with production schedules, identifying opportunities to shift cooling loads without compromising food safety. This intelligence enables the creation of truly energy efficient cooling systems that adapt to operational patterns rather than operating at fixed capacities. The analysis of historical performance data also informs the specification of future components, ensuring replacements are optimized based on actual operating conditions rather than theoretical specifications.

Adopting data-driven cooling strategies establishes a foundation for continuous improvement and unprecedented operational reliability. The ability to predict maintenance needs prevents unexpected downtime, while operational optimization reduces energy consumption and extends equipment lifespan. This intelligent approach to cooling management transforms thermal systems from static infrastructure into dynamic assets that actively contribute to production efficiency and profitability, ensuring sustainable performance improvements throughout the equipment lifecycle.

This ultimate checklist provides a systematic framework for implementing proven cooling efficiency strategies that deliver measurable improvements in performance and cost management. The ten comprehensive strategies address every aspect of industrial thermal management, from component-level optimization to system-wide controls, enabling significant industrial energy savings while enhancing the reliability of your durable cooling infrastructure. By methodically working through this checklist, facility managers can transform their cooling operations from a necessary expense into a strategic advantage.

The checklist begins with foundational strategies focused on core component performance. Item one mandates regular assessment and optimization of evaporator condenser efficiency through cleaning schedules and refrigerant management. Item two implements comprehensive industrial axial fan optimization including blade alignment checks and variable speed drive integration. For operations requiring specialized solutions, item three explores custom cooling production opportunities with manufacturers like Günay Soğutma to create components specifically engineered for peak efficiency within your unique operational environment, forming the basis of truly energy efficient cooling systems.

Sector-specific applications receive dedicated attention in this checklist. For food sector cooling operations, specialized items address hygiene-compliant component selection and defrost cycle optimization based on actual usage data. These targeted approaches, when integrated into comprehensive facility cooling solutions, address the unique challenges of temperature-sensitive processes while maximizing energy efficiency. The checklist also includes advanced control strategies that automatically adjust system operation based on real-time production demands and environmental conditions.

Completing this ultimate checklist establishes a robust foundation for continuous cooling optimization and cost management. The synergistic implementation of these strategies not only reduces immediate energy consumption but also extends equipment lifespan through optimized operating conditions. This proactive, comprehensive approach to cooling management ensures your thermal infrastructure operates at peak efficiency while supporting production reliability, delivering sustainable performance improvements and significant financial returns throughout the equipment lifecycle.

This cooling efficiency masterclass demonstrates how ten strategic upgrades create a virtuous cycle of extended equipment life and operational cost reduction. These advanced cooling efficiency strategies move beyond basic maintenance to fundamentally optimize system performance, delivering substantial industrial energy savings while strengthening your durable cooling infrastructure. The masterclass approach recognizes that the most significant financial benefits come from upgrades that simultaneously improve efficiency and reduce mechanical stress on components, thereby extending their operational lifespan.

The first tier of upgrades focuses on precision component optimization that pays continuous dividends. Upgrade one implements advanced monitoring and control systems for maximizing evaporator condenser efficiency through real-time adjustment of operating parameters. Upgrade two incorporates sophisticated industrial axial fan optimization with aerodynamic enhancements and smart controls that reduce energy consumption while minimizing vibration-induced wear. For facilities with specific operational profiles, upgrade three leverages custom cooling production capabilities from manufacturers like Günay Soğutma to create components that operate at peak efficiency within your exact conditions, forming the core of truly energy efficient cooling systems.

Sector-specific upgrades deliver particularly powerful returns on investment. In food sector cooling applications, upgrades include heat recovery systems that repurpose waste energy and predictive defrost technologies that optimize cycle timing. These specialized enhancements, when integrated into comprehensive facility cooling solutions, address the unique demands of temperature-critical processes while maximizing both efficiency and equipment longevity. The masterclass also includes control system upgrades that automatically adapt cooling output to production schedules, preventing unnecessary operation during downtime.

Implementing these ten strategic upgrades transforms cooling infrastructure into an intelligent, cost-effective asset that actively contributes to operational excellence. The resulting improvements in efficiency reduce energy consumption while the optimized operating conditions significantly extend component service life. This dual benefit approach ensures that every upgrade investment delivers compounding returns through both immediate cost reductions and long-term capital preservation, establishing a foundation for sustained operational reliability and financial performance.

Fill out the form to discover the most suitable high-end products for your projects. Contact Us Now.