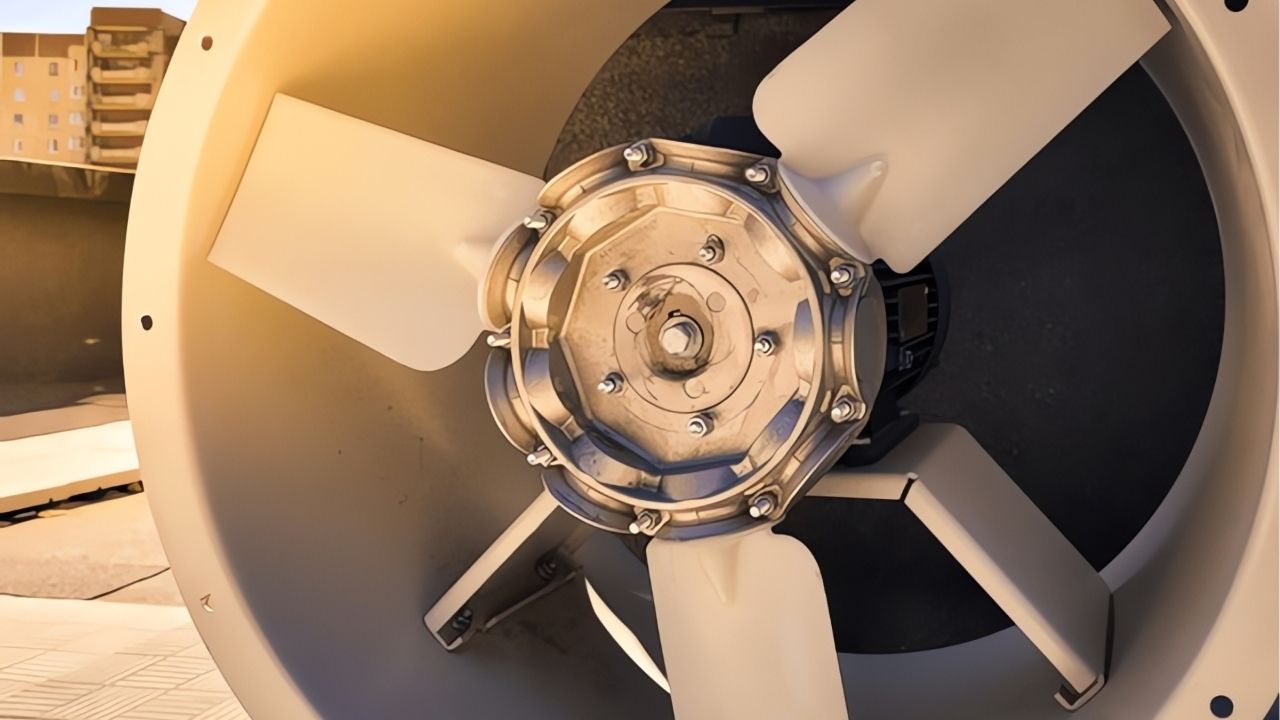

What are Axial Fans? Where are They Used?

Evaluating an industrial evaporator offer requires looking beyond the initial price to assess its long-term impact on operational expenditure and system reliability. A truly valuable proposal must detail how the unit's design and construction will contribute to sustained industrial cooling efficiency and form part of durable cooling systems. The key is to identify offers that prioritize engineering excellence over short-term cost savings, ensuring the evaporator operates efficiently for its entire lifecycle, thereby reducing energy consumption and preventing costly production interruptions.

A critical factor is the manufacturer's approach to custom evaporator manufacturing versus standardized models. A tailored design, engineered for your specific refrigerant, temperature differentials, and load profiles, is fundamental to achieving energy efficient evaporator production outcomes. The offer should explicitly address materials—such as corrosion-resistant coatings for harsh environments—and advanced fin designs that maximize heat transfer. This level of customization, as practiced by established manufacturers like Günay Soğutma, ensures the evaporator is not just a component but an optimized solution integrated into your facility cooling solutions.

The evaluation must also consider the evaporator's role within the broader system, particularly its synergy with a reliable evaporator condenser pair. A high-performance evaporator minimizes the workload on the condenser and compressor, leading to significant energy savings across the entire refrigeration circuit. For applications demanding absolute precision, such as a food sector evaporator, this reliability is non-negotiable to prevent product spoilage and ensure compliance with strict safety standards. The offer should provide performance data projecting these systemic efficiency gains.

Ultimately, a superior industrial evaporator offer is an investment in operational stability. It should demonstrate a clear path to a lower total cost of ownership through reduced energy bills, minimal maintenance needs, and extended service intervals. By selecting a partner capable of true custom cooling production, you secure a critical component that enhances the resilience and profitability of your production line for years to come, making the initial evaluation process a decisive strategic action.

Specifying a custom evaporator requires precise engineering decisions that directly determine its service life and contribution to overall system integrity. A successful custom evaporator manufacturing project begins with confirming critical specifications that ensure the unit becomes a cornerstone of your durable cooling systems. Overlooking details like material compatibility or thermal design can lead to premature failure, undermining the industrial cooling efficiency and reliability that facility cooling solutions demand for continuous operation.

The foremost specification is the construction material, which must be selected for corrosion resistance against specific refrigerants and environmental conditions. For a food sector evaporator, this often means stainless steel to meet hygiene standards and withstand frequent cleaning. The fin density and tube geometry are equally critical; an optimized design maximizes heat transfer for energy efficient evaporator production while ensuring coils resist clogging and are easy to clean, directly impacting maintenance costs and uptime. These factors are non-negotiable in a sound industrial evaporator offer from a reputable provider.

Durability is also a function of mechanical resilience. The design must account for vibration, thermal expansion, and operational pressures to prevent fatigue failures. Manufacturers with a disciplined approach to custom cooling production, such as Günay Soğutma, engineer these factors into the core design, ensuring the evaporator maintains structural integrity over thousands of operating cycles. Furthermore, the unit must be designed as a reliable evaporator condenser partner, meaning its performance characteristics are harmonized with the condenser to prevent system strain and ensure balanced, efficient operation.

Confirming these specifications transforms the procurement from a simple purchase into a strategic investment. A meticulously engineered custom evaporator delivers superior industrial cooling efficiency, reducing energy consumption and extending the lifespan of compressors and other components. By partnering with a manufacturer that prioritizes these critical details, you secure a component that minimizes lifetime costs and maximizes the reliability of your production cooling infrastructure, ensuring long-term operational stability and performance.

The choice between custom and standard industrial evaporators represents a fundamental strategic decision impacting both immediate performance and long-term financial returns. While a standard unit may appear cost-effective initially, a tailored solution from a comprehensive industrial evaporator offer often delivers superior industrial cooling efficiency and a higher return on investment. This analysis hinges on how well the evaporator's design aligns with your specific operational parameters, refrigerant characteristics, and spatial constraints, which directly influences energy consumption and system longevity within your durable cooling systems.

Standard evaporators are designed for average conditions, often leading to compromises in performance. They may operate at off-peak efficiency points, forcing compressors to work harder and increasing energy costs. In contrast, custom evaporator manufacturing optimizes every aspect—from fin density and tube layout to material selection—for your exact application. This precision engineering is the essence of energy efficient evaporator production, resulting in a unit that achieves desired temperatures with minimal energy input and integrates seamlessly as part of facility cooling solutions.

The ROI superiority of custom units becomes particularly evident in specialized applications. For a food sector evaporator, a custom design can incorporate hygienic materials and easy-clean features that reduce downtime for sanitation and prevent contamination. This level of specialized custom cooling production, as executed by manufacturers like Günay Soğutma, ensures the evaporator acts as a reliable evaporator condenser system partner, promoting balanced operation that protects the entire refrigeration circuit from undue stress and premature wear.

Ultimately, the investment in a custom industrial evaporator should be evaluated on its total cost of ownership, not its purchase price. The higher initial cost is offset by significant energy savings, reduced maintenance frequency, and extended equipment life. By choosing a custom solution designed for maximum efficiency and durability, facilities secure not just a component but a optimized thermal management system that enhances production reliability and delivers compounding financial benefits over its operational lifespan.

For facility managers, a strategic industrial evaporator offer is a powerful tool for controlling long-term operational expenditures, particularly maintenance costs. Securing the right offer requires a focus on specifications that enhance durability and simplify upkeep, transforming the evaporator from a maintenance liability into a reliable asset. The goal is to evaluate each custom evaporator manufacturing proposal based on its projected impact on service intervals, spare part consumption, and operational downtime within your durable cooling systems.

The guide begins with demanding clarity on construction features that directly reduce maintenance frequency. This includes specifying easy-access coil designs for simplified cleaning, corrosion-resistant materials suited to the operating environment, and robust headers that withstand thermal cycling. These elements are hallmarks of energy efficient evaporator production, as a clean, well-maintained unit operates with optimal industrial cooling efficiency and places less strain on the entire system. A quality offer from a provider like Günay Soğutma will detail these durability features, demonstrating how their custom cooling production process builds longevity into the component.

Beyond physical construction, the evaporator's integration is critical. It must be engineered as a reliable evaporator condenser pair to ensure balanced system operation. An improperly matched evaporator can cause refrigerant floodback or high superheat, leading to compressor damage and expensive repairs. For specialized needs, such as a food sector evaporator, the offer should include hygienic design features that minimize downtime for sanitation cycles, a significant contributor to maintenance labor costs. This level of integration is essential for effective facility cooling solutions.

Ultimately, securing a custom evaporator offer that reduces maintenance costs is an exercise in forward-thinking procurement. By prioritizing designs that emphasize ease of service, material resilience, and system harmony, facility managers can significantly lower their total cost of ownership. The initial investment in a high-quality, custom-engineered evaporator pays continuous dividends through reduced labor, fewer spare parts, and uninterrupted production, solidifying the cooling system's role as a dependable cornerstone of operational efficiency.

Tailored evaporator manufacturing addresses the unique thermal management challenges faced by the food and energy sectors, where cooling performance directly impacts product safety, process efficiency, and operational profitability. Unlike standard units, a precisely engineered custom evaporator manufacturing project optimizes the component for specific load profiles, environmental conditions, and regulatory requirements. This approach is fundamental to achieving the industrial cooling efficiency and reliability required for durable cooling systems in these critical industries, transforming a generic component into a strategic asset.

In the food industry, a food sector evaporator must be designed with hygiene as a primary concern. This involves selecting easy-clean stainless steel materials, designing coils with optimal spacing to prevent bacterial growth, and ensuring the unit withstands frequent washdowns without corrosion. This specialized custom cooling production prevents contamination risks and reduces sanitation downtime, which are significant cost drivers. Such precision, as delivered by manufacturers like Günay Soğutma, ensures the evaporator contributes to a reliable evaporator condenser system that maintains precise temperatures for product integrity and compliance.

For the energy sector, optimization focuses on maximizing heat transfer under potentially harsh conditions and variable loads. A tailored evaporator can be designed for higher pressure ratings, specific refrigerant blends, and exceptional fouling resistance. This leads to superior energy efficient evaporator production outcomes, as the unit operates at peak efficiency, reducing the energy draw of compressors and supporting the continuous operation essential for energy production facilities. A well-crafted industrial evaporator offer for this sector will detail these performance enhancements.

The ability to specify every aspect of the evaporator through custom evaporator manufacturing results in a component that is intrinsically more reliable and efficient than an off-the-shelf alternative. This optimization directly lowers the total cost of ownership by reducing energy consumption, minimizing maintenance interventions, and extending the equipment's service life. For facility managers seeking robust facility cooling solutions, investing in a tailored evaporator is a definitive step toward securing long-term operational stability and profitability in both the food and energy sectors.

Strategic investment in custom industrial evaporators represents a fundamental shift from viewing cooling components as expenses to treating them as assets that actively reduce the total cost of ownership. While a standard industrial evaporator offer may present a lower initial price, a tailored solution through custom evaporator manufacturing is engineered to minimize lifetime operational costs. This approach optimizes the evaporator for superior industrial cooling efficiency, directly impacting energy consumption, maintenance frequency, and system longevity within your durable cooling systems.

The financial benefits materialize through precisely engineered features that standard units cannot offer. A custom design ensures optimal heat transfer surface area and refrigerant circuiting, which is the core of energy efficient evaporator production. This precision reduces compressor workload, leading to substantial and continuous energy savings. Furthermore, specifying corrosion-resistant materials and robust construction, as seen in components from manufacturers like Günay Soğutma, drastically extends service life and reduces the need for replacements, making it a cornerstone of reliable facility cooling solutions.

Sector-specific applications highlight the TCO advantage even more clearly. A food sector evaporator designed with hygienic, easy-clean features minimizes downtime for sanitation and prevents costly product spoilage from temperature deviations. This level of specialized custom cooling production ensures the evaporator functions as a reliable evaporator condenser system partner, preventing unbalanced operation that leads to premature failure of other expensive components like compressors.

Ultimately, investing in a custom industrial evaporator is a deliberate strategy for financial optimization in industrial operations. The higher initial investment is strategically allocated to achieve compounding returns through lower utility bills, reduced maintenance labor and parts costs, and eliminated production downtime. By prioritizing engineering excellence and long-term performance in the procurement process, facilities can transform their cooling infrastructure into a predictable, low-maintenance asset that delivers measurable financial benefits throughout its extended operational life.

Accepting an industrial evaporator offer without rigorous questioning can jeopardize production line reliability and inflate operational costs. The right questions transform the evaluation process from a price comparison into a strategic assessment of uptime protection. Key inquiries should focus on how the evaporator's design and manufacturing quality contribute to industrial cooling efficiency and its role within durable cooling systems, ensuring the selected unit actively prevents downtime rather than becoming its cause.

Critical questions must address the specifics of the custom evaporator manufacturing process. Inquire about the materials' corrosion resistance for your specific environment and the design features that facilitate easy maintenance, such as cleanable coil spacing. Ask for performance data verifying the unit's contribution to energy efficient evaporator production, as higher efficiency directly correlates with reduced mechanical stress and longer component life. Providers with proven expertise, like Günay Soğutma, will readily provide these details, demonstrating how their custom cooling production enhances reliability.

Further questions should explore system integration and sector-specific requirements. Crucially, ask how the evaporator is guaranteed to function as part of a reliable evaporator condenser pair to avoid system imbalance. For a food sector evaporator, demand specifics on hygienic certifications and design features that minimize sanitation downtime. These factors are essential for facility cooling solutions that support continuous operation, as they prevent failures that halt production lines and incur significant financial losses.

Ultimately, the answers to these key questions provide a clear picture of the evaporator's true value in safeguarding uptime. A high-quality offer will demonstrate a deep understanding of operational challenges and present an engineered solution that prioritizes durability and efficiency. By conducting this due diligence, facility managers can confidently select an evaporator that acts as a reliable foundation for production, minimizing unplanned downtime and contributing to a lower total cost of ownership through sustained, trouble-free operation.

Maximizing the lifespan of an industrial cooling system begins with a strategic evaluation of the evaporator proposal, as this component's quality directly influences the longevity of the entire refrigeration circuit. A superior industrial evaporator offer goes beyond basic specifications to demonstrate how its design philosophy contributes to building durable cooling systems. The proposal should clearly articulate how the evaporator's construction and performance will enhance industrial cooling efficiency while minimizing wear on compressors and other critical components, thereby extending the system's operational life.

The proposal must detail the engineering principles behind the custom evaporator manufacturing process. Look for explicit information on material selection—such as specific aluminum alloy grades or stainless steel types—that guarantee corrosion resistance in your operating environment. The document should also highlight design features that promote energy efficient evaporator production, like optimized fin patterns and tube circuits that reduce pressure drop and compressor load. Established manufacturers like Günay Soğutma typically provide this level of detail, showcasing their commitment to custom cooling production that prioritizes longevity.

A high-quality proposal will also address system harmony, proving the evaporator is engineered as a reliable evaporator condenser match. This ensures balanced operation, preventing issues like liquid floodback to the compressor that can cause catastrophic failure. For specialized applications, such as a food sector evaporator, the proposal must include features that withstand rigorous cleaning protocols without degrading. These considerations are fundamental to creating facility cooling solutions that operate reliably for decades rather than years.

Ultimately, selecting an evaporator based on a proposal that emphasizes durability and systemic efficiency is a direct investment in the cooling system's future. The right component reduces the frequency and cost of maintenance, lowers energy consumption over its entire lifecycle, and protects the capital investment in the larger system. By prioritizing these factors during the procurement process, facility managers can secure a cooling infrastructure that delivers maximum uptime and a significantly extended service life, ensuring long-term operational and financial stability.

Fill out the form to discover the most suitable high-end products for your projects. Contact Us Now.