Media

Strong Connections Through Fair Participation

Hostech 2025

This year, Hostech by TUSİD 2025 was held on May 27–31 at the Istanbul TÜYAP Fair and Congress Center. As Turkey’s largest and Europe’s second largest HORECA fair, it welcomed approximately 35,000 visitors from 140 countries across a 45,000 m⊃2; exhibition area. Günay Soğutma proudly took part in this major event. At our booth, we showcased our innovative industrial cooling products and sustainable solutions, while also connecting with professionals from both Turkey and abroad. For us, Hostech was more than just a fair; it was a valuable opportunity to build new business partnerships, strengthen existing relationships, and represent our company more powerfully in the international market. The strong interest from foreign buyer delegations once again proved that we are on the right track. We sincerely thank all our visitors and look forward to meeting again at upcoming fairs.

Read More

Chillventa 2022

Thank You to Everyone Who Joined Us at Chillventa 2022! We would like to extend our heartfelt thanks to all participants and valued customers who visited our stand at Chillventa 2022. Your interest and the time you shared with us were a tremendous source of motivation, allowing us to present our innovative cooling solutions and share our vision within the industry. The connections we have built with you strengthen our leadership goals and inspire us to provide more efficient and sustainable solutions in the future. We look forward to building new projects and strong partnerships together!

Read More

Chillventa 2024

Günay Soğutma participated in the Chillventa 2024 Fair, seizing the opportunity to showcase the latest innovations in the sector. During the event, we shared our newest technologies and solutions in the field of cooling and air conditioning with attendees. The fair served as an important platform to connect with industry professionals and foster new collaborations. Visitors had the chance to explore our innovative products and sustainable solutions while gaining insight into our customer-oriented approach. Chillventa 2024 provided not only an opportunity for knowledge exchange but also a chance to keep up with the latest industry trends. We are pleased to have established new business connections and strengthened existing relationships through this experience. We would like to extend our gratitude to all the visitors who joined us at the fair. We eagerly look forward to meeting you again at future events!

Read More

HVAC-R Egypt Expo 2024

With the solutions we presented at HVAC-R EGYPT EXPO, we reinforced our reliability and sustainability principles in the refrigeration and heat transfer sector in Egypt.

Read More

HVAC-R London 2023

HVAC Refrigeration Live, as an important event in the industry, offered a very valuable experience for us. We would like to express our sincere thanks to all exhibitors and customers who visited our booth for their interest and time. The strong ties we have established with you give us great motivation to maintain our leadership in the industry and to carry our solution-oriented approach even further.

Read More

ISK-SODEX Istanbul 2023

We participated in ISK-SODEX 2023, one of the leading exhibitions of the air conditioning industry. We would like to thank all our customers and exhibitors who showed great interest in our stand.

Read More

AquaTherm Exhibition 2023

Thank you to all our customers and exhibitors who visited our booth at AquaTherm Exhibition 2023. Your intense interest made us very happy and we were proud to share our innovations in the sector.

Read More

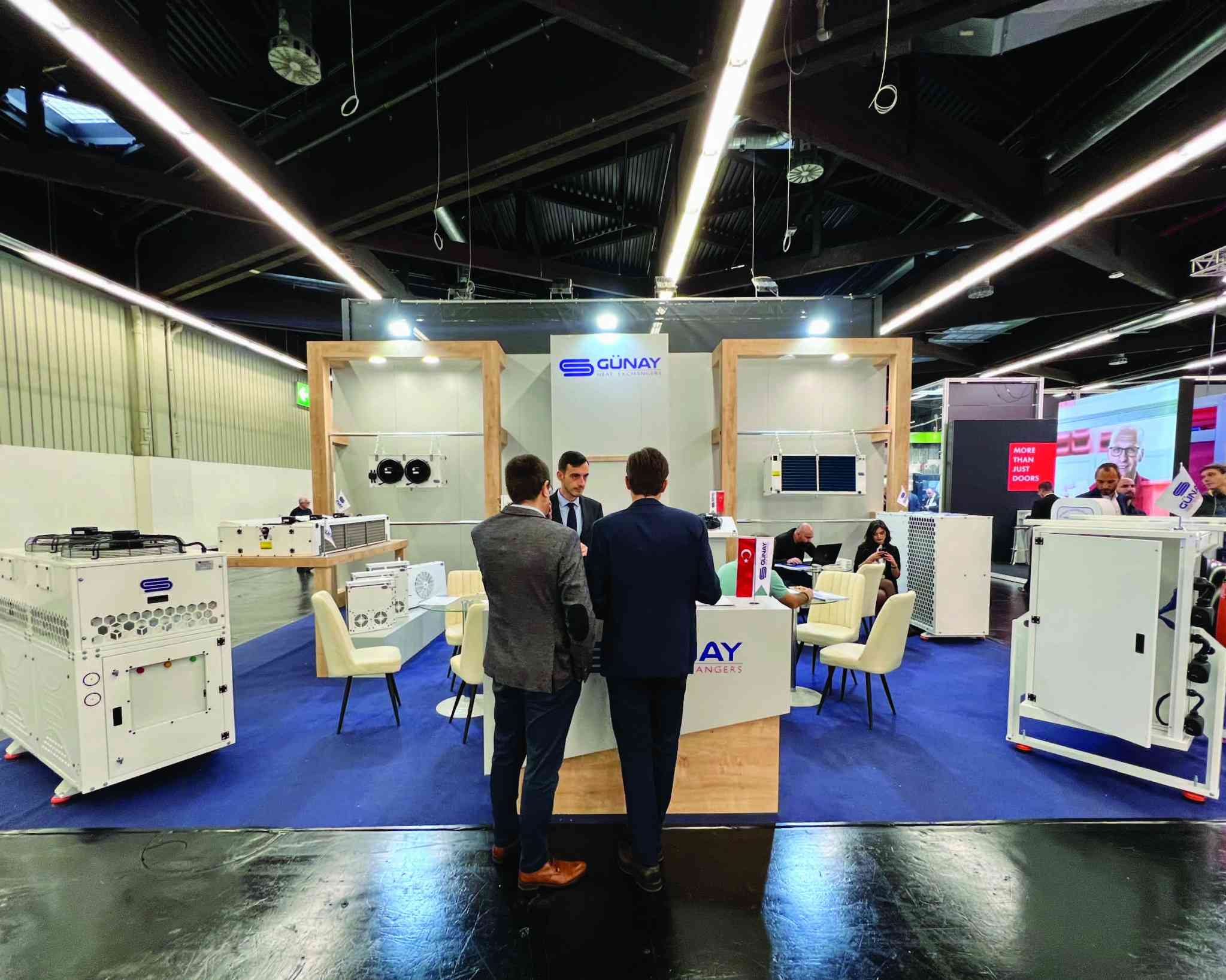

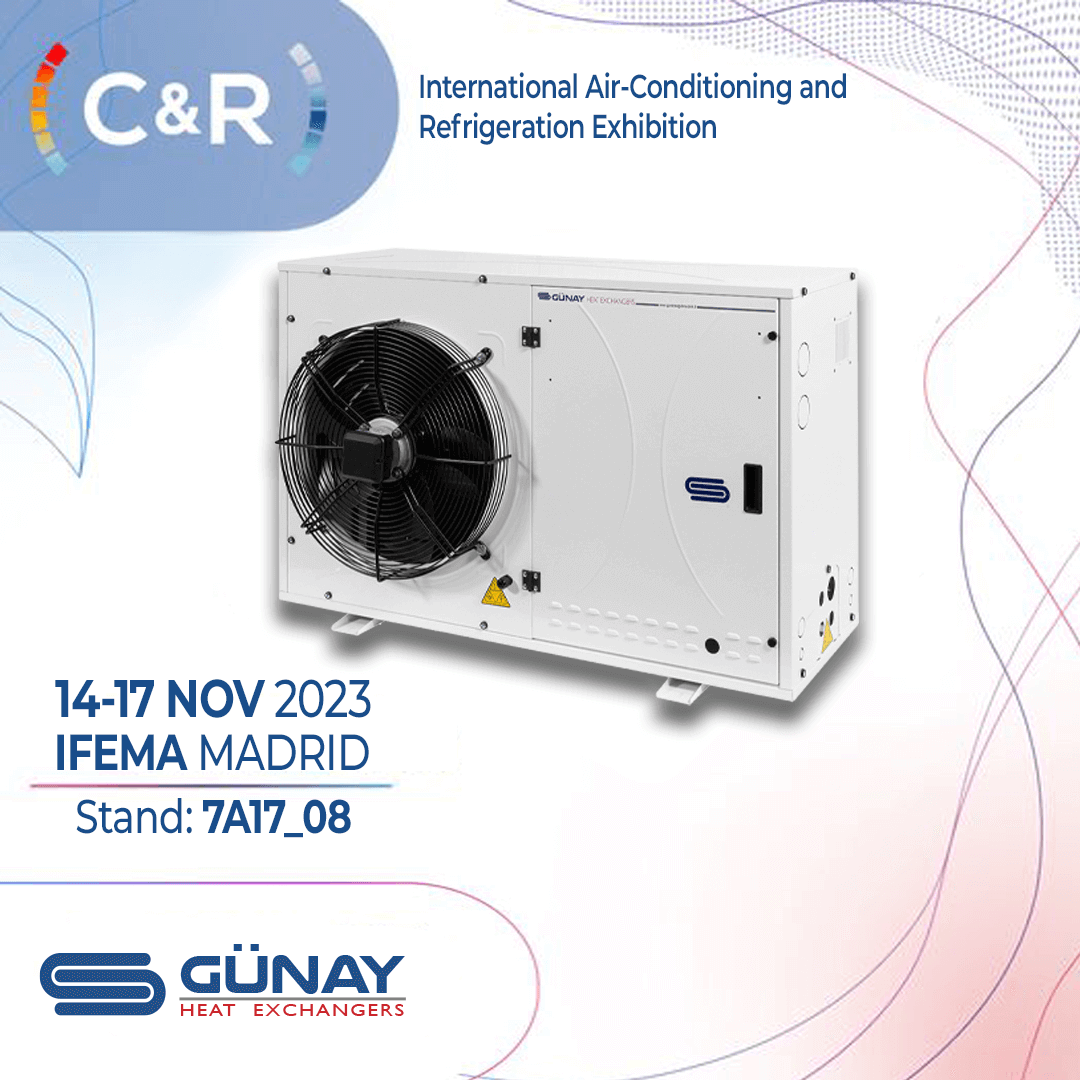

C&R Madrid 2023

The C&R Madrid 2023 fair was an unforgettable experience for us as an important event in the industry. We extend our heartfelt thanks to all participants and customers who visited our stand for their interest and time. The connections we established with you inspire us to continue our leadership in the industry and strengthen our solution-oriented approach. We look forward to building a more efficient and sustainable future togethe

Read MoreBlog

Axial Fan Types Performance and Application Areas

Table of Contents Axial Fan Types That Support Maximum Energy Efficiency in Industrial Cooling An Axial Fan Performance Guide for High Efficiency Cooling and Lower Operating Costs Axial Fan Types and Their Industrial Applications for Optimized Airflow Efficiency A Comparison of Standard and Custom Axial Fans in Terms of Cooling Reliability and Energy Savings Improving Axial Fan Selection for Reduced Maintenance Downtime and Higher Cooling Performance Axial Fan Applications in the Food and Energy Sectors and Their Impact on Efficiency Analyzing Durability and Energy Consumption Through Axial Fan Performance Measurements Axial Fan Types That Support Maximum Energy Efficiency in Industrial Cooling Selecting the correct axial fan type is a critical decision for achieving maximum energy efficiency in any industrial cooling system, directly influencing operational costs and environmental footprint. The choice between propeller, vane axial, and tube axial fans hinges on specific performance requirements like static pressure, airflow volume, and system resistance. Understanding axial fan types and performance characteristics is the first step toward reducing energy consumption and enhancing the overall reliable cooling infrastructure of a production facility. For most industrial cooling fan applications requiring high airflow at low to medium static pressures, vane axial fans often deliver superior efficiency. Their guided vanes recover static pressure by straightening the airflow, allowing the fan to move more air with less power compared to a simple propeller fan. This makes them ideal for applications supporting high-efficiency condenser evaporator units, where consistent, optimized airflow is essential for peak heat transfer. Investing in these energy saving fan types translates directly into lower kilowatt-hour consumption and a smaller carbon footprint. The pursuit of ultimate efficiency often leads to a custom axial fan application, where the fan is engineered to match the precise aerodynamic profile of the cooling system. This level of precision is a hallmark of Günay Soğutma axial fan production, which utilizes advanced design and testing to ensure optimal performance. A durable axial fan built with robust materials and precision-balanced impellers not only saves energy but also operates quietly and with minimal vibration, extending the life of the entire assembly. Ultimately, the most energy-efficient axial fan is the one perfectly suited to its specific duty point within your system. An improperly selected fan will waste energy, generate excessive noise, and potentially cause premature failure. By consulting with experts and selecting a fan based on rigorous performance data, you can ensure your cooling system operates at its thermodynamic peak, delivering reliable performance while minimizing lifetime operating expenses. An Axial Fan Performance Guide for High Efficiency Cooling and Lower Operating Costs Understanding axial fan performance is fundamental to designing a system that achieves high-efficiency cooling and realizes significant lower operational costs. The selection process must carefully balance airflow requirements, static pressure demands, and acoustic considerations to ensure the fan operates at its best efficiency point. This guide provides a framework for evaluating axial fan types and performance curves to make an informed choice that supports a reliable cooling infrastructure and minimizes energy waste. The first step is to accurately define the system's requirements, including the required cubic feet per minute (CFM) of airflow and the static pressure the fan must overcome. This is particularly critical for industrial cooling fan applications involving a high-efficiency condenser evaporator, where insufficient airflow can drastically reduce heat exchange efficiency and increase compressor load. For such demanding roles, energy saving fan types like vane axial models are often preferred due to their ability to handle higher pressures more efficiently than basic propeller fans. When standard offerings do not perfectly match the system curve, a custom axial fan application becomes the optimal path. This approach, central to Günay Soğutma axial fan production, involves tailoring the blade angle, diameter, and hub ratio to achieve peak performance for a specific set of conditions. The result is a durable axial fan that operates with lower power consumption, reduced noise, and minimal vibration, contributing to extended equipment life and lower maintenance costs. By meticulously selecting the right axial fan based on performance data rather than approximate sizing, facilities can secure long-term financial and operational benefits. The correct fan ensures that the cooling system works as intended, preventing energy overuse and mechanical stress. This proactive investment in performance-optimized components is a proven strategy for enhancing system reliability, achieving sustainability goals, and maintaining a competitive edge through controlled operating expenses. Axial Fan Types and Their Industrial Applications for Optimized Airflow Efficiency The strategic selection of axial fan types is paramount for maximizing airflow efficiency and ensuring extended equipment lifespan in industrial settings. Each fan category—propeller, tube axial, and vane axial—possesses distinct axial fan types and performance characteristics suited to specific pressure and flow requirements. Matching the correct fan to its industrial cooling fan applications prevents system strain, reduces energy consumption, and forms the basis of a reliable cooling infrastructure. Propeller fans excel in moving large volumes of air against very low static pressure, making them suitable for general ventilation. However, for forced-draft applications critical to high-efficiency condenser evaporator performance, vane axial fans are superior. Their incorporated guide vanes straighten airflow, recovering pressure and allowing the unit to operate efficiently against the resistance of dense coil fins. These energy saving fan types are essential for maintaining optimal heat transfer rates without overloading the motor, directly impacting the system's overall energy draw. In scenarios with unique spatial constraints or abnormal operating conditions, a custom axial fan application provides the perfect solution. This engineering-centric approach, a specialty of Günay Soğutma axial fan production, tailors the fan's aerodynamics and structure to the exact application. The outcome is a durable axial fan that delivers precise airflow while operating with minimal vibration and acoustic noise, factors that significantly contribute to the longevity of the fan itself and the surrounding structure. Ultimately, understanding the correlation between fan selection, efficiency, and durability allows facility managers to make capital investments that yield long-term returns. A correctly applied fan minimizes power costs, reduces the need for frequent maintenance, and prevents premature failure of both the fan and the components it serves. This informed approach to component selection is a cornerstone of building a cost-effective, high-performance industrial cooling system designed for years of reliable service. A Comparison of Standard and Custom Axial Fans in Terms of Cooling Reliability and Energy Savings The choice between standard and custom axial fans represents a fundamental trade-off between initial cost and long-term performance, directly impacting cooling reliability and energy savings. Standard fans offer a quick, cost-effective solution for applications with common requirements, but they may operate away from their peak efficiency if system parameters are not a perfect match. A performance comparison reveals that for critical industrial cooling fan applications, a tailored solution often delivers superior operational and financial outcomes. Standard axial fans are mass-produced to cover a wide range of general axial fan types and performance needs, making them suitable for basic ventilation or systems with forgiving performance tolerances. However, when integrated with a high-performance high-efficiency condenser evaporator, a standard fan might not provide the precise airflow and pressure required, leading to reduced heat exchange and higher energy consumption. In contrast, a custom axial fan application is engineered from the outset to meet the exact system curve, ensuring it operates as one of the true energy saving fan types. The engineering process for a custom fan, as exemplified by Günay Soğutma axial fan production, involves optimizing the blade profile, hub ratio, and materials for the specific application. This results in a durable axial fan that not only consumes less power but also exhibits lower vibration levels and noise, contributing to a more stable reliable cooling infrastructure. The precision balancing and robust construction inherent in custom fans directly extend the operational life of the unit and its supporting structure. While the upfront investment for a custom fan is higher, the long-term benefits in energy efficiency, reduced maintenance, and unwavering reliability typically yield a significantly lower total cost of ownership. For facilities where cooling is integral to production, the enhanced performance and predictability of a custom solution provide a substantial return on investment, making it the strategically sound choice for ensuring continuous, cost-effective operation. Improving Axial Fan Selection for Reduced Maintenance Downtime and Higher Cooling Performance Optimizing axial fan selection is a proactive engineering strategy to achieve dual objectives significant reduced maintenance downtime and consistent higher cooling performance. This process requires moving beyond basic airflow specifications to consider factors like operational environment, bearing technology, and impeller balance. A methodical approach to selection, grounded in a deep understanding of axial fan types and performance, directly contributes to a more robust and reliable cooling infrastructure. The foundation of optimization is accurate system characterization. Engineers must calculate the exact static pressure and airflow (CFM) required for optimal operation of key components like the high-efficiency condenser evaporator. Selecting a fan that operates at its best efficiency point for these conditions is crucial; an undersized fan will strain to meet demand, while an oversized one will waste energy and potentially recirculate air. For complex industrial cooling fan applications, this often leads to the specification of energy saving fan types like vane axial models, which offer superior pressure capabilities. To minimize maintenance, priority must be given to features that enhance durability. This includes specifying a durable axial fan constructed with corrosion-resistant coatings, premium bearings with extended service life, and a dynamically balanced impeller to prevent vibration-induced wear. In non-standard installations, a custom axial fan application ensures these features are integrated seamlessly. This level of precision manufacturing is a cornerstone of Günay Soğutma axial fan production, where discipline ensures every fan is built for longevity. By following this optimized selection protocol, facilities effectively invest in predictability. The right fan operates smoothly, reduces the stress on motors and drives, and maintains designed airflow for peak heat transfer efficiency year after year. This translates into fewer emergency repairs, lower spare parts inventory, and a cooling system that reliably supports production targets, ultimately delivering a lower total cost of ownership and enhanced operational control. Axial Fan Applications in the Food and Energy Sectors and Their Impact on Efficiency Axial fans are indispensable components for boosting efficiency and sustainability ROI in the food and energy sectors, where cooling reliability directly impacts product quality, safety, and power generation. The correct application of specific axial fan types and performance profiles is critical for managing unique environmental challenges, from hygienic requirements in food processing to heat rejection in power plants. This guide outlines how strategic fan selection underpins a reliable cooling infrastructure that delivers both operational and environmental returns. In the food sector, industrial cooling fan applications demand fans that support precise temperature control for blast freezers, chillers, and maturation rooms. These systems often utilize high-efficiency condenser evaporator units where consistent, robust airflow is non-negotiable. Here, energy saving fan types with corrosion-resistant coatings and easy-clean designs are essential. For complex layouts, a custom axial fan application ensures optimal performance while adhering to stringent hygiene protocols, a standard upheld in Günay Soğutma axial fan production. The energy sector presents different challenges, with axial fans critical for cooling turbines, transformers, and large-scale process heat exchangers. These applications require a durable axial fan capable of withstanding harsh outdoor conditions, variable loads, and continuous operation. The sustainability ROI is calculated through reduced auxiliary power consumption and increased availability of the primary power-generating asset. Precision-engineered fans minimize the parasitic load they represent, making the entire energy production process more efficient and profitable. By viewing axial fans not as commodities but as engineered solutions, businesses in both sectors can achieve remarkable gains. The investment in a correctly specified, high-quality fan pays dividends through lower energy bills, compliance with environmental standards, reduced water consumption in evaporative systems, and unparalleled equipment reliability. This strategic approach transforms the axial fan from a simple component into a key driver of sustainable, cost-effective industrial operations. Analyzing Durability and Energy Consumption Through Axial Fan Performance Measurements Mastering key axial fan performance metrics is the definitive method for achieving long-lasting durability and securing lower energy expenses in industrial cooling systems. These quantifiable measurements—including airflow (CFM), static pressure, fan efficiency, and sound power level—provide an objective framework for selection far superior to guesswork. A data-driven approach grounded in a thorough understanding of axial fan types and performance ensures the fan operates harmoniously within the reliable cooling infrastructure, avoiding the inefficiencies that lead to high costs and premature failure. The primary metric is the system curve, which defines the relationship between required airflow and the static pressure the fan must overcome. Accurately plotting this curve for your specific industrial cooling fan applications is the first step. The ideal fan selection is one whose performance curve intersects the system curve at or near its peak efficiency point. This is especially critical when the fan serves a high-efficiency condenser evaporator, as improper airflow can degrade the entire system's thermal performance. Choosing from true energy saving fan types based on this data guarantees minimal power consumption. Durability metrics focus on mechanical integrity. These include impeller balance grades (e.g., ISO 1940 G6.3 or better) to minimize vibration, and bearing life calculations (L10 life) based on operational speed and load. For challenging environments, a custom axial fan application allows for the optimization of these parameters. This engineering precision, a hallmark of Günay Soğutma axial fan production, results in a durable axial fan that withstands continuous operation without degradation in performance or reliability. By rigorously applying these performance metrics during the selection process, facility managers make an investment that pays continuous returns. The correctly specified fan uses less electricity, requires less maintenance, and operates reliably for its entire design life. This methodology transforms the axial fan from a potential source of problems into a cornerstone of an efficient, predictable, and cost-effective industrial cooling operation.

Read More

Condenser Price and Energy Savings

Table of Contents The True Cost of an Energy Efficient Condenser and Its Long Term Return on Investment Industrial Condenser Cost Framework Covering Pricing Energy Efficiency and Operational Savings Key Factors That Determine Condenser Pricing and Energy Savings Calculating Return on Investment Through Pricing and Energy Reduction in High Efficiency Condensers A Comparison of Standard and Custom Condensers in Terms of Energy Savings Balancing Initial Cost with Long Term Energy and Maintenance Savings in Durable Condenser Selection A Guide to Balancing Pricing Energy Efficiency and Cooling Performance in Condenser Investments The True Cost of an Energy Efficient Condenser and Its Long Term Return on Investment Evaluating the true industrial condenser price requires a shift in perspective from initial purchase cost to total lifetime value, particularly when investing in high-efficiency industrial cooling solutions. The superior performance of an energy-optimized condenser directly translates into measurable long-term ROI through drastically reduced electrical consumption and enhanced system stability. Securing a detailed energy saving condenser quote is therefore the first step in quantifying these operational savings and understanding how a higher-quality component pays for itself over its service life. The engineering behind a high-efficiency condenser focuses on maximizing heat transfer while minimizing pressure drop and fan power requirements. This is a core strength of Günay Soğutma condenser production, where advanced coil designs and materials are used to achieve optimal thermal performance. When paired with a correctly specified custom axial fan, the system operates at its peak efficiency curve, reducing the energy draw of the entire refrigeration circuit. This synergy is critical for building a reliable cooling infrastructure that can withstand continuous operation in food processing or energy generation environments. This focus on durability also significantly impacts the perceived durable condenser cost. A condenser built with robust materials and corrosion-resistant coatings will have a longer operational lifespan, delaying capital replacement expenses. Furthermore, a well-designed unit simplifies evaporator condenser maintenance routines, with features like accessible cleaning ports and resilient fin stacks that reduce downtime and labor costs. This engineered reliability ensures that the system contributes to production uptime rather than posing a risk of failure. Ultimately, the most accurate assessment of cost comes from a project-specific quotation that accounts for your facility's unique load profile, ambient conditions, and efficiency goals. This tailored analysis reveals the direct link between the initial investment in a high-performance condenser and the cumulative financial benefits of lower utility bills, reduced maintenance, and uninterrupted production. Requesting a comprehensive quote is not merely a pricing exercise but a strategic planning tool for achieving a cooler, more efficient, and more profitable operation. Industrial Condenser Cost Framework Covering Pricing Energy Efficiency and Operational Savings The true industrial condenser price extends far beyond the initial invoice, encompassing a complex equation of energy consumption, maintenance frequency, and operational reliability over the unit's entire lifecycle. For facility managers focused on high-efficiency industrial cooling, understanding this total cost of ownership is essential for making capital decisions that yield substantial operational savings. A comprehensive view reveals that the most economical condenser is often the one with superior engineering that minimizes ongoing expenses. Energy efficiency is the most significant variable in this calculation. A condenser designed for optimal heat rejection allows compressors to operate at lower head pressures, drastically reducing power draw. This performance is a benchmark of Günay Soğutma condenser production, where precision engineering ensures maximum thermal transfer with minimal energy input. Integrating such a unit with a perfectly matched custom axial fan creates a synergistic effect, further enhancing efficiency and solidifying the foundation of a reliable cooling infrastructure. Durability is another critical cost factor. The durable condenser cost is justified by its extended service life and resistance to harsh industrial environments, which defers replacement capital. Robust construction also simplifies evaporator condenser maintenance, requiring less frequent cleaning and reducing the risk of unscheduled downtime that halts production. Obtaining an energy saving condenser quote that details these long-term benefits provides a transparent view of the investment's value. Ultimately, the most strategic approach to condenser procurement is to evaluate specifications through the lens of lifetime performance. The marginally higher initial cost of a high-efficiency, durable model is consistently offset by years of lower electricity bills, reduced maintenance labor, and unwavering cooling capacity that protects production output. By prioritizing engineering excellence over short-term price, industrial operations can secure not just a component, but a pillar of sustainable and cost-effective facility management. Key Factors That Determine Condenser Pricing and Energy Savings Accurately projecting your industrial condenser price and potential energy savings requires a detailed analysis of several technical and operational factors unique to your facility. These variables directly influence the initial investment and the long-term financial return, making a customized energy saving condenser quote an indispensable tool for strategic planning. Understanding these determinants allows managers to make informed decisions that balance upfront cost with lifecycle performance for high-efficiency industrial cooling. The primary cost drivers include thermal capacity, materials of construction, and design complexity. A condenser for a large food processing plant will have a different specification and durable condenser cost compared to one for a compact energy sector application. The selection of materials, such as corrosion-resistant coatings for harsh environments, is a critical factor in longevity and a key aspect of Günay Soğutma condenser production. Furthermore, the integration with a custom axial fan optimized for specific static pressure and airflow requirements adds another layer of performance and cost consideration. Energy savings are predominantly determined by the condenser's heat transfer efficiency and the associated reduction in compressor workload. A highly efficient unit lowers the system's head pressure, which is the largest contributor to energy consumption. This efficiency is not just about the condenser itself but its role within the entire reliable cooling infrastructure. Ease of access for cleaning and inspection also plays a major role in sustained efficiency, impacting long-term evaporator condenser maintenance costs and preventing gradual performance degradation. Given these interdependencies, the most accurate assessment comes from providing a manufacturer with specific operational data cooling load, ambient conditions, desired refrigerant, and runtime. This enables the creation of a solution precisely engineered for your facility's needs, ensuring that every aspect of the industrial condenser price is justified by a corresponding gain in efficiency, durability, and operational reliability. Requesting a detailed quote based on these factors is the first step toward a optimized, cost-effective cooling system. Calculating Return on Investment Through Pricing and Energy Reduction in High Efficiency Condensers Evaluating high-efficiency condenser pricing necessitates a rigorous ROI calculation that accounts for both immediate energy reduction and long-term maintenance savings. The premium associated with a superior unit is not an expense but a strategic investment, with payback periods often dramatically shortened by continuous operational benefits. Securing a detailed energy saving condenser quote that includes projected performance data is essential for validating this investment against baseline industrial condenser price models and justifying the capital allocation. The most substantial ROI component is energy reduction. A high-efficiency condenser lowers system head pressure, which directly decreases compressor power consumption. This core principle of high-efficiency industrial cooling is engineered into products through advanced thermal designs, such as those utilized in Günay Soğutma condenser production. When this condenser is paired with a custom axial fan calibrated for optimal airflow, the synergistic effect can reduce total system energy use by significant percentages, creating a predictable and recurring financial return. Maintenance savings constitute the second critical variable in the ROI equation. The durable condenser cost is offset by a longer service interval and reduced susceptibility to failure. Features like corrosion-resistant materials and accessible coil designs simplify evaporator condenser maintenance, cutting labor hours and chemical costs while maximizing production uptime. This durability is a cornerstone of a reliable cooling infrastructure, preventing costly emergency repairs and production stoppages. The calculation is straightforward sum the annual energy savings and reduced maintenance costs, then divide by the initial investment premium over a standard unit. This exercise consistently demonstrates that the higher initial industrial condenser price for an efficient model is quickly amortized. By focusing on total cost of ownership rather than purchase price alone, facility managers can make data-driven decisions that enhance operational profitability and secure a cooling system built for long-term, cost-effective performance. A Comparison of Standard and Custom Condensers in Terms of Energy Savings The decision between a standard and custom condenser involves a critical price comparison that must evaluate long-term energy savings against the initial industrial condenser price. While a standard unit may appear cost-effective upfront, a custom solution engineered for your specific production line often delivers superior efficiency and a faster return on investment. The key is to assess which option provides the optimal balance for your unique operational demands and contributes to a reliable cooling infrastructure. Standard condensers are designed for broad applications with common load and ambient conditions. They offer a lower entry point but may operate suboptimally if your facility has unique challenges, such as high ambient temperatures or variable loads. This can lead to higher energy consumption as the system compensates for the mismatch. In contrast, a custom condenser, like those available through Günay Soğutma condenser production, is precisely sized and configured. It ensures high-efficiency industrial cooling by perfectly matching the thermal load, which minimizes compressor work and maximizes energy savings from day one. The integration of ancillary components further illustrates the value of customization. A standard condenser paired with a generic fan may suffer from airflow inefficiencies. However, a custom design can incorporate a perfectly matched custom axial fan, creating a synergistic system that operates at peak efficiency. This precision engineering also impacts long-term costs; a bespoke unit often has a higher durable condenser cost upfront but significantly reduces evaporator condenser maintenance and extends the equipment's service life. Ultimately, the most accurate assessment comes from a project-specific energy saving condenser quote that compares both options side-by-side. This analysis will quantify the energy savings of a custom fit against the lower initial cost of a standard model. For most modern production lines where cooling is critical, the long-term financial and operational benefits of a tailored solution consistently outweigh the short-term savings of a generic unit, making it the superior investment for sustained profitability and performance. Balancing Initial Cost with Long Term Energy and Maintenance Savings in Durable Condenser Selection Requesting a detailed quote for a durable condenser is the most effective way to visualize how a higher initial industrial condenser price converts into substantial long-term savings on energy and maintenance. This financial translation is critical for justifying capital expenditure in high-efficiency industrial cooling components, moving the focus from simple procurement to strategic investment in operational reliability. An energy saving condenser quote provides the concrete data needed to forecast ROI and understand the true value of engineering excellence. The premium associated with a durable unit directly purchases enhanced performance characteristics. This includes superior materials that resist corrosion, advanced coil designs that maximize heat transfer, and construction that withstands industrial stresses. These features are central to Günay Soğutma condenser production, ensuring each unit contributes to a reliable cooling infrastructure. When this condenser is integrated with a custom axial fan, the system operates at optimal efficiency, reducing the compressor's energy load and delivering immediate cost savings on electricity. The long-term financial benefits are twofold. First, the reduced energy consumption becomes a permanent line-item saving. Second, the robust construction drastically lowers lifetime evaporator condenser maintenance costs. Fewer cleanings, reduced risk of leaks, and extended service intervals minimize both planned and unplanned downtime, protecting production schedules. This makes the durable condenser cost a proactive investment in uptime and predictability. Therefore, the act of obtaining a quote is not a passive inquiry but an active step in financial planning for your facility's cooling needs. It quantifies the direct correlation between quality engineering and operational economics. By analyzing a comprehensive quote, managers can confidently invest in a condenser that delivers not just cooling capacity, but also measurable financial returns through lower operating expenses and unwavering reliability for years to come. A Guide to Balancing Pricing Energy Efficiency and Cooling Performance in Condenser Investments Optimizing condenser investment requires a strategic approach that balances the initial industrial condenser price against guaranteed gains in energy efficiency and long-term performance. This process begins with a clear understanding that the lowest purchase price often leads to the highest total cost of ownership, while a strategically selected unit becomes a profit center through operational savings. The key is to utilize tools like an energy saving condenser quote to make data-driven decisions that enhance your facility's reliable cooling infrastructure. The first step is accurate sizing and specification. A condenser that is either oversized or undersized for the application will operate inefficiently, increasing energy consumption and wear. This precision is a fundamental aspect of Günay Soğutma condenser production, where engineering discipline ensures perfect alignment with thermal loads. For maximum high-efficiency industrial cooling, the condenser must be viewed as part of a system, ideally paired with a custom axial fan to create a perfectly balanced heat rejection unit that minimizes total power draw. Next, evaluate the durable condenser cost in the context of lifecycle expenses. Investing in robust materials and corrosion protection may increase the upfront price but dramatically reduces future evaporator condenser maintenance costs and frequency. This durability directly translates to higher uptime and predictability, as the risk of unscheduled repairs is minimized. A well-built condenser maintains its efficiency over a longer period, ensuring that the investment continues to pay dividends year after year without degradation. Ultimately, optimization is achieved by selecting a condenser that offers the best performance per unit of lifetime cost. This means prioritizing engineering quality, efficiency certifications, and compatibility with your specific operational environment. By following this how-to guide, facility managers can transform their condenser procurement from a simple replacement task into a strategic upgrade that delivers lower energy bills, reduced maintenance, and superior cooling performance that reliably supports production goals.

Read More

Resistor Installation Safety and Correct Connection Guide

Table of Contents Improving Energy Efficiency in Industrial Cooling Through Proper Resistance Installation Durable Cooling Performance Through Secure Resistance Connections and Reduced Downtime The Impact of Resistance Installation Errors on Maintenance and Efficiency and Solution Approaches Resistance Safety for Long Term Reliability and Lower Operating Costs System Lifespan and Energy Savings Through a Professional Resistance Connection Process A Comparison of Standard and Custom Resistance Installations for Durability and Efficiency High Efficiency Cooling and Sustainable Returns Through Resistance Connection Optimization Improving Energy Efficiency in Industrial Cooling Through Proper Resistance Installation In the demanding environments of industrial facilities, achieving optimal energy efficiency is paramount for controlling operational costs and ensuring sustainability. A frequently overlooked yet critical component in this equation is the correct resistance connection within cooling systems. Improper resistor installation safety practices can lead to significant energy waste, increased electrical strain on compressors and fans, and premature system failure. This guide outlines how meticulous installation directly translates to lower kilowatt-hour consumption and a more robust reliable cooling infrastructure, forming the foundation for long-term operational savings. The principle behind this efficiency gain lies in electrical stability. A properly installed resistor ensures that auxiliary components, such as those in durable evaporator condenser production units, receive a consistent and precise electrical signal. This prevents power fluctuations that force motors to work harder, thus reducing the overall energy draw of the system. For components like the custom axial fan application, this stability is crucial; an erratic signal can diminish airflow and heat exchange efficiency, directly impacting the cooling capacity and forcing the system to run longer cycles. Adhering to a strict resistor installation safety guide is therefore not just a protective measure but a direct investment in performance. This technical precision is a hallmark of Günay Soğutma expert solutions, where disciplined manufacturing ensures that every component, including resistors, is engineered for seamless integration. The capability for both serial production and custom production allows for the creation of systems perfectly tailored to specific industrial loads, whether for a food processing line requiring precise temperature control or an energy sector plant needing robust heat rejection. This integration minimizes electrical resistance at connection points, a key factor in achieving an energy-efficient resistor connection that supports the entire cooling circuit. Ultimately, the focus on proper resistor installation is a core aspect of proactive industrial cooling system maintenance. By eliminating a common source of electrical inefficiency, facilities can dramatically reduce energy costs, extend the operational life of expensive compressors and fans, and minimize unplanned downtime. This approach, supported by high-quality components from established manufacturers, transforms the cooling system from a utility cost center into a strategic asset for production reliability and long-term financial performance, ensuring that every kilowatt of energy is utilized for maximum cooling effect. Durable Cooling Performance Through Secure Resistance Connections and Reduced Downtime Unplanned downtime in industrial cooling is a costly event, often stemming from preventable electrical failures. A primary defense against such disruptions is a rigorous resistor installation safety guide focused on achieving a perfect correct resistance connection. Loose terminals, corrosion, or thermal overload can cascade into system-wide issues, compromising the reliable cooling infrastructure that production lines depend on. This guide establishes the critical link between meticulous electrical practices and the uninterrupted, durable industrial cooling performance required in high-stakes environments. The consequences of neglecting connection safety are severe. An insecure resistor connection generates excessive heat, increasing resistance and creating a vicious cycle that can damage sensitive control boards and degrade adjacent components. This is particularly detrimental to systems featuring durable evaporator condenser production units, where stable electrical input is essential for precise pressure and temperature control. Similarly, a fault in the circuit governing a custom axial fan application can lead to reduced airflow, causing compressor strain and elevating the risk of a catastrophic shutdown. Proactive industrial cooling system maintenance must therefore prioritize electrical integrity. Implementing a robust safety protocol is a core principle behind Günay Soğutma expert solutions, where disciplined manufacturing ensures components are built for longevity and safe integration. The flexibility of both serial production for standard applications and custom production for unique facility needs guarantees that resistors are correctly specified for their electrical load. This precision engineering is fundamental to an energy-efficient resistor connection, as it minimizes power loss and heat generation at the source. By adhering to these safety principles, facility managers transform their cooling systems from a vulnerability into a pillar of operational reliability. The direct outcomes are a significant reduction in maintenance emergencies, extended equipment lifecycle, and consistent cooling capacity that protects production quality. Investing in correctly installed, high-quality components is the most effective strategy for safeguarding against downtime, ensuring that your cooling infrastructure performs reliably under the most demanding conditions, year after year. The Impact of Resistance Installation Errors on Maintenance and Efficiency and Solution Approaches Common resistor installation safety guide violations, such as overtightened terminals or incorrect wattage selection, create immediate and long-term financial drains for industrial facilities. These errors prevent a correct resistance connection, leading to chronic inefficiencies that undermine even the most robust reliable cooling infrastructure. The result is a continuous cycle of wasted energy, emergency repairs, and compromised cooling performance that directly impacts production throughput and operational budgets. One critical mistake is the mismatching of resistor specifications to the load requirements of key components like those in durable evaporator condenser production systems. An undersized resistor will overheat and fail prematurely, while an oversized one can cause improper cycling of fan motors. This is especially damaging in a custom axial fan application, where precise speed control is essential for optimal heat exchange. Such errors transform routine industrial cooling system maintenance into a frequent, costly firefighting exercise, eroding the system's designed efficiency and durability. Günay Soğutma expert solutions address these pitfalls at the source through disciplined engineering and manufacturing. The company's approach, leveraging both serial production consistency and custom production adaptability, ensures that every resistor is precisely matched to its intended circuit. This eliminates guesswork and improper sizing, which is foundational to achieving a stable, energy-efficient resistor connection that performs reliably under continuous industrial loads. By specifying components engineered to prevent common installation errors, facilities can break the cycle of reactive repairs and energy waste. The outcome is a cooling system characterized by predictable performance, significantly reduced operational expenses, and extended equipment service life. Partnering with manufacturers who prioritize precision in both component design and integration guidance is the most effective strategy for turning a potential liability into a cornerstone of durable, cost-effective industrial cooling. Resistance Safety for Long Term Reliability and Lower Operating Costs A comprehensive resistor installation safety guide is not merely a procedural document but a strategic asset for protecting capital-intensive cooling equipment. The goal is to achieve a flawless correct resistance connection that safeguards the entire system from electrical faults, thereby ensuring the long-term reliability required for continuous industrial operations. This proactive approach directly translates to significantly reduced operational costs by preventing energy waste and catastrophic component failures that necessitate expensive emergency repairs and production halts. The core of this protection lies in understanding how a single point of failure can destabilize an entire system. An unsafe resistor connection generates excessive heat, which degrades insulation and can lead to short circuits. This poses a particular risk to sophisticated components from durable evaporator condenser production lines, where precise thermal management is critical. In applications involving a custom axial fan application, an electrical fault can disrupt airflow balance, causing inefficient heat rejection and forcing compressors to overwork. Integrating safety protocols into standard industrial cooling system maintenance routines is therefore essential for preserving system integrity. This disciplined methodology is exemplified by Günay Soğutma expert solutions, where the integration of modern technology with rigorous manufacturing standards produces components designed for safety and endurance. The company's capability for both high-volume serial production and tailored custom production ensures that every resistor is application-matched, which is the first step toward an inherently energy-efficient resistor connection. This precision engineering minimizes parasitic power loss and thermal stress, contributing directly to a more stable and efficient reliable cooling infrastructure. Ultimately, viewing resistor safety through the lens of risk mitigation and total cost of ownership empowers facility managers to make smarter investments. By prioritizing components and installation practices that prevent failures before they occur, businesses secure uninterrupted production, maximize the lifespan of their cooling assets, and achieve a lower overall cost of operation. This strategic focus on electrical safety is a fundamental pillar for building a cooling infrastructure that delivers unwavering performance and financial predictability. System Lifespan and Energy Savings Through a Professional Resistance Connection Process A systematic approach to electrical integration is fundamental to achieving maximum cooling system lifespan and substantial energy savings in demanding industrial applications. This begins with a meticulous, step-by-step procedure grounded in a professional resistor installation safety guide. The objective is a perfect correct resistance connection that eliminates power loss, minimizes heat generation, and ensures the stable operation essential for a reliable cooling infrastructure. Each step, from specification to torque verification, directly influences long-term operational costs and equipment durability. The first critical step is selecting a resistor with the exact specifications for the intended load. This is particularly vital for protecting components from durable evaporator condenser production units, where incorrect resistance can lead to erratic valve operation and inefficient heat transfer. For systems utilizing a custom axial fan application, precise resistor matching ensures accurate speed control, which is crucial for maintaining designed airflow and static pressure without overloading the motor. This precision selection is a cornerstone of preventative industrial cooling system maintenance, preventing inefficiencies at the source. The installation process itself demands discipline. Proper terminal preparation, correct torque application, and the use of anti-oxidation compounds are non-negotiable for creating an energy-efficient resistor connection. These practices, which are standard in Günay Soğutma expert solutions, ensure minimal electrical resistance at the junction point. The company's disciplined approach, supported by both serial production for consistency and custom production for specific challenges, guarantees that components are not only high-quality but also perfectly suited for a seamless and reliable integration. By following this professional protocol, facilities achieve a dual victory dramatic reductions in energy consumption due to minimized electrical losses and a significant extension of the cooling system's operational life. This methodical investment in installation quality transforms the resistor from a simple component into a key contributor to system-wide efficiency and reliability, delivering measurable returns through lower utility bills and deferred capital expenditure on premature equipment replacements. A Comparison of Standard and Custom Resistance Installations for Durability and Efficiency The choice between standard and custom resistor installation is a strategic decision that directly impacts the durability and efficiency of your production line's cooling system. While off-the-shelf components offer simplicity, a tailored approach often delivers superior performance by ensuring a perfect correct resistance connection for specific operational demands. This alignment is critical for building a truly reliable cooling infrastructure that can withstand unique environmental stresses and load profiles, ultimately determining long-term energy consumption and maintenance frequency. Standard resistors are suitable for applications with common, predictable electrical characteristics. However, in complex systems featuring components from durable evaporator condenser production lines or specialized setups like a custom axial fan application, a one-size-fits-all solution can be inadequate. An incorrectly specified resistor may lead to improper motor speeds or control signal fluctuations, forcing the system to operate outside its ideal efficiency band. This undermines the goals of proactive industrial cooling system maintenance and can prevent achieving an energy-efficient resistor connection. This is where the flexibility of manufacturers offering both paths becomes invaluable. Günay Soğutma expert solutions, for instance, provide the economies of scale through disciplined serial production for standard needs, while their engineered custom production capability addresses unique challenges. A custom resistor is designed to match the exact electrical load, ambient conditions, and performance requirements of the application, a level of precision that standard components cannot guarantee. This tailored approach is a core principle of any comprehensive resistor installation safety guide, prioritizing optimal performance over mere compatibility. For facilities seeking to maximize return on investment, the custom path typically leads to greater gains in both efficiency and equipment lifespan. The initial investment in a perfectly matched component pays dividends through reduced energy waste, lower incidence of failure, and extended service life for expensive cooling assets. By choosing a solution engineered for your specific production line, you transform the cooling system from a generic utility into a finely tuned asset that actively contributes to operational reliability and cost control. High Efficiency Cooling and Sustainable Returns Through Resistance Connection Optimization Optimizing electrical connections within industrial cooling systems is a direct pathway to achieving a sustainable ROI and significantly lower expenses. This process begins with a meticulous focus on creating an energy-efficient resistor connection, which minimizes parasitic power loss and thermal stress. Adhering to a rigorous resistor installation safety guide ensures that this optimization is not only effective but also durable, forming the bedrock of a reliable cooling infrastructure that delivers consistent performance under full load. The technical methodology for optimization involves precise specification and installation to achieve a perfect correct resistance connection. This is especially critical when integrating with high-performance components from durable evaporator condenser production systems, where stable electrical signals are necessary for accurate pressure and temperature control. In a custom axial fan application, an optimized resistor ensures the fan motor receives clean power, enabling it to operate at its peak efficiency curve without unnecessary energy expenditure. This level of precision elevates standard industrial cooling system maintenance into a strategic efficiency-enhancing practice. The principles of optimization are central to Günay Soğutma expert solutions, where a disciplined manufacturing process guarantees component quality and performance. The strategic use of serial production for standardized reliability, combined with the flexibility of custom production for application-specific challenges, ensures that every resistor contributes to system-wide efficiency. This engineered approach eliminates the guesswork and compromises that often lead to energy waste and premature component failure in less optimized systems. By implementing these optimization techniques, industrial facilities can transform their cooling operations from a significant cost center into a model of efficiency. The result is a continuous reduction in kilowatt-hour consumption, extended operational life for major components like compressors and fans, and a dramatic decrease in unplanned downtime. This proactive investment in connection quality delivers a compounding financial return, solidifying the cooling system's role as a key contributor to both production reliability and overall profitability.

Read More

Evaporator Selection Capacity Calculation and Design Steps

Table of Contents An Approach to Calculating Evaporator Capacity for Energy Efficiency and System Reliability 5 Steps Supporting Cooling Performance and Cost Balance in Industrial Evaporator Selection An Evaporator Design Process Delivering Long Term Durability and Lower Operating Costs A Capacity Calculation Guide for Cooling Efficiency in Standard and Custom Evaporators Key Evaporator Selection Criteria for Cooling Reliability and Efficiency in the Food Industry A Method for Reducing Energy Costs Through Accurate Evaporator Capacity Calculation The Impact of Evaporator Design on Equipment Lifespan and Production Continuity An Engineering Guide to Evaporator Selection and Sizing for Sustainable Cooling Performance An Approach to Calculating Evaporator Capacity for Energy Efficiency and System Reliability Accurate evaporator capacity calculation is the foundational engineering step that determines both the energy performance and operational reliability of industrial cooling systems. Precise sizing ensures the evaporator matches the thermal load without overworking the compressor, directly impacting industrial cooling efficiency and system longevity. This calculation process must account for refrigerant properties, temperature differentials, airflow rates, and specific application requirements to create durable cooling systems that operate at optimal efficiency points throughout their lifecycle. The calculation methodology begins with determining the total heat load, incorporating factors like product cooling requirements, heat infiltration, and operational cycles. This data feeds into industrial evaporator design parameters that optimize surface area, refrigerant circuiting, and fin density. Proper evaporator selection guide principles dictate choosing a unit with 10-15 percent capacity margin to handle peak loads without forcing continuous maximum operation. This precision engineering approach, as practiced in energy efficient evaporator production by manufacturers like Günay Soğutma, ensures components operate efficiently across varying conditions rather than at inefficient extremes. Application-specific calculations yield particularly significant benefits. For food sector evaporator installations, calculations must incorporate defrost cycle impacts and hygiene compliance requirements that affect effective capacity. These specialized considerations highlight the value of custom cooling production for applications where standard units cannot meet precise operational parameters. The resulting properly sized evaporator becomes the cornerstone of effective facility cooling solutions, preventing the energy waste and component stress caused by undersized or oversized equipment. Investing time in meticulous capacity calculation delivers substantial operational returns through multiple channels. Correctly sized evaporators reduce compressor cycling and power consumption while maintaining stable temperatures that protect both product quality and equipment integrity. This systematic approach to sizing ensures your cooling infrastructure operates as an efficient, reliable asset rather than a source of constant adjustment and repair, maximizing both energy savings and system reliability throughout the equipment's service life. 5 Steps Supporting Cooling Performance and Cost Balance in Industrial Evaporator Selection This ultimate evaporator selection guide provides a systematic five-step methodology for choosing industrial evaporators that deliver optimal cooling performance while minimizing operational costs. Proper selection directly influences industrial cooling efficiency, energy consumption, and maintenance requirements, making it a critical decision for any facility seeking to build durable cooling systems. The five-step process ensures technical specifications align with operational demands, preventing the common pitfalls of undersizing or oversizing that lead to inefficient operation and premature component failure. The guide begins with comprehensive load analysis and precise evaporator capacity calculation to establish baseline requirements. Step two evaluates refrigerant compatibility and temperature ranges to ensure optimal heat transfer characteristics. Step three focuses on industrial evaporator design features such as coil configuration, fin spacing, and material selection based on environmental conditions. This disciplined approach to selection supports energy efficient evaporator production principles, as manufacturers like Günay Soğutma engineer components that perform efficiently within specified operational parameters rather than requiring continuous maximum output. Application-specific considerations form step four of the selection process. For food sector evaporator applications, this involves evaluating hygiene requirements, defrost system compatibility, and sanitation access needs. This level of specialized assessment often leads to custom cooling production solutions that standard units cannot provide. The final step integrates the selected evaporator into comprehensive facility cooling solutions, ensuring compatibility with existing condensers and control systems to achieve balanced, efficient operation. Following this five-step selection methodology delivers substantial financial and operational benefits. Correctly chosen evaporators operate at peak efficiency, reducing energy consumption while maintaining stable temperatures that protect both product quality and equipment longevity. This systematic approach to selection ensures your cooling infrastructure functions as a reliable, cost-effective asset rather than a source of constant adjustment, maximizing performance and minimizing total cost of ownership throughout the equipment's service life. An Evaporator Design Process Delivering Long Term Durability and Lower Operating Costs Strategic industrial evaporator design steps directly determine both equipment longevity and operational economics in industrial cooling applications. A meticulously engineered evaporator reduces energy consumption while withstanding years of continuous operation, forming the core of durable cooling systems that minimize lifetime costs. The design process must balance thermal performance with mechanical resilience, ensuring the component contributes to overall industrial cooling efficiency while requiring minimal maintenance throughout its service life. The design process begins with material selection based on corrosion resistance and structural integrity for the specific operating environment. This is followed by evaporator capacity calculation that determines optimal surface area and refrigerant circuiting to prevent excessive pressure drops and compressor strain. These fundamental steps in energy efficient evaporator production ensure components operate at peak efficiency points rather than at energy-wasting extremes. Manufacturers with engineering discipline, such as Günay Soğutma, incorporate these principles into both standard and custom cooling production to create evaporators that excel in specific applications. Application-specific design considerations significantly enhance durability and efficiency. For food sector evaporator applications, design steps include implementing hygienic fin spacing, easy-clean surfaces, and corrosion-resistant coatings that withstand frequent sanitation. These specialized design features prevent performance degradation and extend service intervals, making them invaluable components of comprehensive facility cooling solutions. Following a rigorous evaporator selection guide during the design phase ensures all operational parameters are addressed before manufacturing begins. Investing in proper evaporator design steps delivers compounding returns through reduced energy consumption, extended equipment life, and minimized maintenance requirements. A well-designed evaporator operates efficiently across varying loads, reducing compressor workload and preventing the systemic stress that leads to premature component failures. This engineering-focused approach to evaporator creation ensures your cooling infrastructure remains a reliable, cost-effective asset that supports production goals while delivering significant operational savings throughout its extended service life. A Capacity Calculation Guide for Cooling Efficiency in Standard and Custom Evaporators The choice between custom and standard evaporators fundamentally influences cooling system performance, with precise evaporator capacity calculation serving as the critical differentiator in achieving higher efficiency. Standard units offer convenience but often operate at off-peak efficiency points due to design compromises, while custom solutions are engineered to match exact operational parameters. This capacity calculation guide demonstrates how proper sizing and specification directly enhance industrial cooling efficiency and contribute to building durable cooling systems that minimize lifetime operational costs. The capacity calculation process reveals when standard evaporators suffice versus when custom cooling production becomes necessary. Standard units work well for applications with common parameters and stable loads, but unusual space constraints, specific refrigerant requirements, or variable operating conditions typically warrant custom solutions. This engineering decision directly impacts energy efficient evaporator production outcomes, as manufacturers like Günay Soğutma can optimize industrial evaporator design for peak performance in specific environments rather than accepting the limitations of mass-produced components. Application-specific calculations particularly highlight the custom advantage. For food sector evaporator installations, calculations must incorporate hygiene requirements, defrost cycle impacts, and sanitation access that standard units may not accommodate. This specialized approach ensures the evaporator integrates seamlessly into comprehensive facility cooling solutions without efficiency compromises. Following a detailed evaporator selection guide during the calculation phase identifies these unique requirements before procurement decisions are made. The capacity calculation process ultimately determines the return on investment for either approach. While custom evaporators involve higher initial costs, their precision engineering typically delivers greater energy savings and longer service life, reducing total cost of ownership. This guide empowers facility managers to make data-driven decisions that balance upfront investment against long-term operational benefits, ensuring their cooling infrastructure operates at peak efficiency while supporting production reliability throughout its service life. Key Evaporator Selection Criteria for Cooling Reliability and Efficiency in the Food Industry Selecting the right food sector evaporator requires addressing unique factors that directly impact both food safety compliance and operational economics. Unlike general industrial applications, food cooling demands precision temperature control combined with hygienic design, making evaporator selection a critical determinant of both industrial cooling efficiency and regulatory compliance. A comprehensive evaporator selection guide for food applications must prioritize features that prevent contamination while maintaining optimal performance within durable cooling systems. The primary selection factors begin with material compatibility and hygienic design. Food-grade stainless steel construction, cleanable fin spacing, and smooth surfaces that resist bacterial growth are non-negotiable for any food sector evaporator. These features must be integrated during the industrial evaporator design phase while maintaining thermal performance through precise evaporator capacity calculation. This specialized approach to energy efficient evaporator production often necessitates custom cooling production from manufacturers like Günay Soğutma, as standard units frequently compromise either hygiene or efficiency. Operational factors including defrost system compatibility and temperature stability are equally critical. The evaporator must maintain consistent temperatures during both cooling and defrost cycles to prevent product quality issues. These performance requirements make the evaporator a cornerstone of reliable facility cooling solutions for food processing, where temperature deviations can result in substantial product loss. The selection process must also consider the evaporator's integration with sanitation protocols, ensuring it withstands frequent cleaning without corrosion or performance degradation. Proper evaporator selection for food sector applications delivers significant operational benefits beyond basic cooling function. The right unit reduces energy consumption through optimized operation, minimizes downtime for cleaning and maintenance, and ensures compliance with food safety regulations. This strategic approach to selection transforms the evaporator from a simple component into a critical asset that supports both product quality and operational efficiency, delivering long-term reliability and cost savings throughout its service life. A Method for Reducing Energy Costs Through Accurate Evaporator Capacity Calculation Precision evaporator capacity calculation is the engineering discipline that directly translates into minimized energy costs and optimized system performance in industrial cooling applications. This step-by-step methodology ensures evaporators operate at their peak efficiency points rather than struggling with inadequate capacity or wasting energy through oversizing. Proper calculation forms the foundation of energy efficient evaporator production and is essential for achieving superior industrial cooling efficiency within durable cooling systems. The calculation method begins with comprehensive load analysis, accounting for product cooling requirements, heat infiltration, internal heat generation, and operational cycles. This data feeds into refrigerant-specific calculations that determine optimum evaporating temperatures and superheat settings. These precise inputs guide subsequent industrial evaporator design decisions regarding surface area, fin density, and circuit configuration. Manufacturers committed to engineering excellence, such as Günay Soğutma, utilize these calculations in their custom cooling production processes to create evaporators that match exact operational parameters rather than approximate requirements. Application-specific calculations yield particularly significant energy savings. For food sector evaporator installations, calculations must incorporate defrost cycle impacts, humidity control requirements, and sanitation protocols that affect effective capacity. This precision approach ensures the evaporator integrates seamlessly into comprehensive facility cooling solutions without the energy penalties of improper sizing. Following a rigorous evaporator selection guide based on these calculations prevents the common operational inefficiencies that inflate energy costs. Implementing this precision calculation methodology delivers substantial financial returns through multiple channels. Correctly sized evaporators reduce compressor cycling and power consumption while maintaining stable temperatures that protect both product quality and equipment integrity. This systematic approach to capacity calculation ensures your cooling infrastructure operates as an efficient, cost-effective asset rather than a source of constant energy waste, maximizing both operational savings and system reliability throughout the equipment's service life. The Impact of Evaporator Design on Equipment Lifespan and Production Continuity Proper industrial evaporator design steps directly correlate with extended equipment lifespan and enhanced production reliability in industrial cooling systems. A meticulously engineered evaporator reduces mechanical stress on the entire refrigeration circuit while maintaining optimal performance, serving as the cornerstone of durable cooling systems that maximize uptime. The design process must balance thermal efficiency with structural integrity, ensuring the component contributes to overall industrial cooling efficiency while withstanding years of continuous operation. The design methodology begins with precise evaporator capacity calculation to prevent the compressor cycling and system strain caused by improper sizing. This is followed by material selection based on corrosion resistance and mechanical strength specific to the operating environment. These fundamental steps in energy efficient evaporator production ensure components operate within their optimal performance range rather than at energy-wasting extremes. Manufacturers with engineering discipline, such as Günay Soğutma, incorporate these principles into both standard and custom cooling production to create evaporators that excel in specific applications while following a comprehensive evaporator selection guide. Application-specific design features significantly enhance reliability and uptime. For food sector evaporator applications, design steps include implementing hygienic fin spacing, easy-clean surfaces, and corrosion-resistant coatings that withstand frequent sanitation without performance degradation. These specialized design elements prevent the contamination risks and maintenance downtime that disrupt production schedules, making them critical components of comprehensive facility cooling solutions. The right design ensures defrost systems operate efficiently without causing temperature fluctuations that could compromise product quality. Investing in proper evaporator design steps delivers compounding benefits through reduced maintenance frequency, extended component life, and uninterrupted production operations. A well-designed evaporator operates efficiently across varying loads, reducing compressor workload and preventing the systemic stress that leads to premature failures. This engineering-focused approach to evaporator creation ensures your cooling infrastructure remains a reliable asset that supports production goals while delivering significant operational savings and enhanced uptime throughout its extended service life. An Engineering Guide to Evaporator Selection and Sizing for Sustainable Cooling Performance This engineering guide to evaporator selection and sizing provides a systematic approach to achieving sustainable cooling performance that balances immediate operational needs with long-term reliability. Proper implementation of this evaporator selection guide ensures components operate at peak industrial cooling efficiency while contributing to the development of truly durable cooling systems. The methodology emphasizes precision evaporator capacity calculation and appropriate industrial evaporator design as the foundation for sustainable thermal management that minimizes environmental impact while maximizing economic returns. The selection process begins with comprehensive load analysis that accounts for both current requirements and anticipated future capacity needs. This forward-looking approach to evaporator capacity calculation prevents the energy waste associated with undersized or oversized equipment. The resulting specifications guide the industrial evaporator design process, ensuring optimal surface area, refrigerant circuiting, and material selection for the specific application. This engineering discipline is central to energy efficient evaporator production by manufacturers like Günay Soğutma, who often employ custom cooling production to meet precise sustainability objectives. Sustainable performance requires special consideration for application-specific requirements. For food sector evaporator installations, this involves selecting materials and designs that minimize environmental impact while meeting stringent hygiene standards. These specialized components become integral parts of comprehensive facility cooling solutions that reduce energy consumption and extend equipment life. The guide emphasizes selecting evaporators with features that facilitate maintenance and cleaning, reducing the resource consumption associated with frequent service interventions. Following this engineering guide delivers significant sustainability benefits through reduced energy consumption, extended equipment lifespan, and minimized maintenance requirements. Properly selected and sized evaporators operate efficiently across their entire load range, reducing compressor workload and preventing the energy waste associated with inappropriate sizing. This systematic approach to evaporator specification ensures your cooling infrastructure supports both operational efficiency and environmental responsibility, delivering sustainable performance that protects both your bottom line and long-term operational capabilities.

Read More

Cooling Efficiency and Energy Saving Strategies