At Günay Heat Exchangers, we work to protect natural resources and build a sustainable future. We focus on using eco-friendly practices and maximizing energy efficiency to reduce our impact on the environment. We aim to meet future needs today and add value to society and the environment, ensuring a sustainable life for future generations

Your Global Solution Partner

We Offer Maximum Efficiency and Satisfaction to Our Customers with Our Services and Products at Global Standards.

40+ Years of Experience Leading Solutions in Cooling and Heating Sector

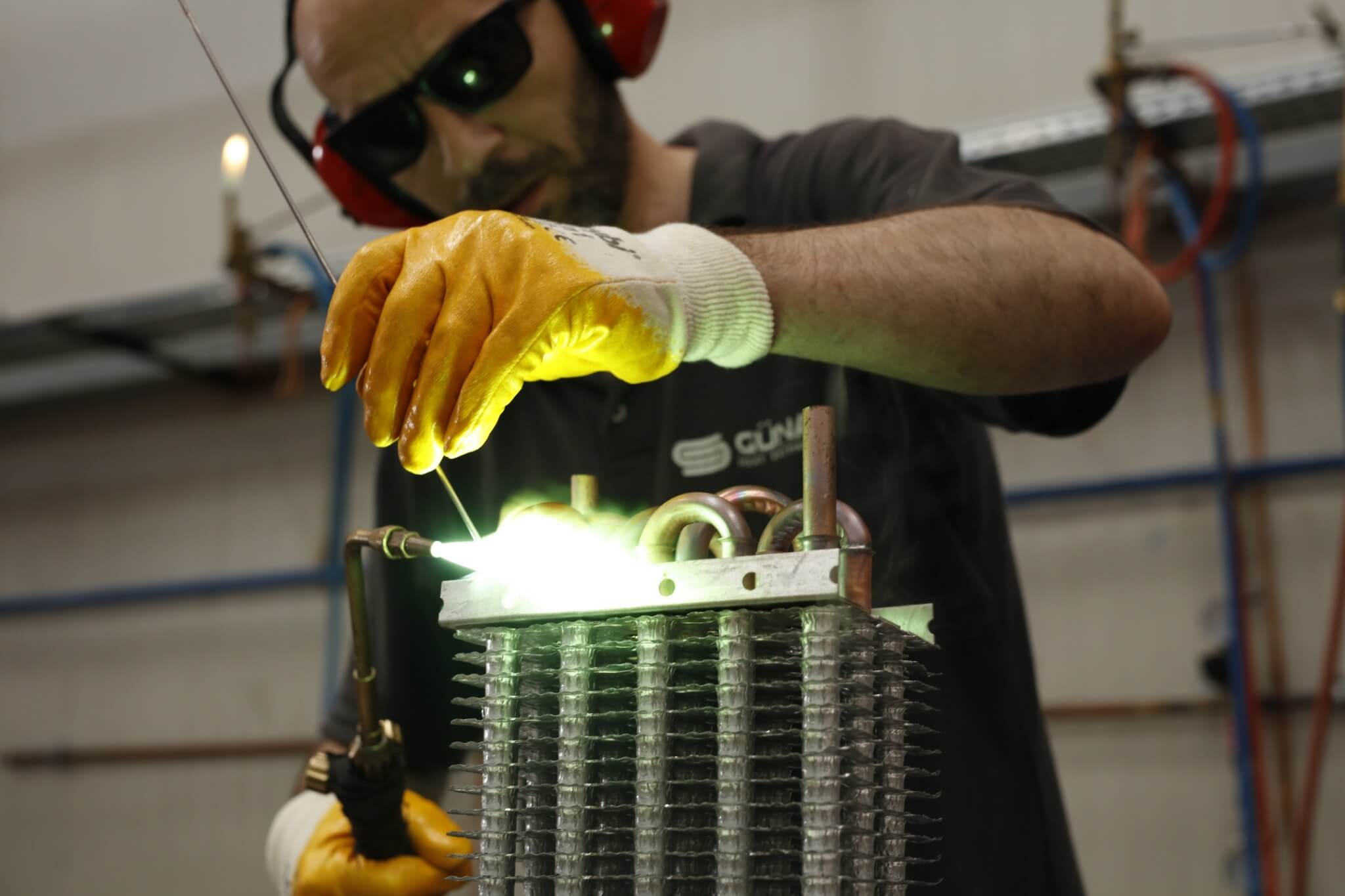

Since its establishment in 1986, our company has been serving with serial and special production evaporators, condensers and heat exchangers.

Your Power in the Sector: Gunay Cooling

Since 1986, we offer innovative and customized solutions with our high quality in Evaporators, Condensers and Heat Exchangers. We are working for you with our continuously developing infrastructure and customer-oriented approach.

Innovative Cooling Solutions Offering High Efficiency

Since its establishment in 1986, our company has been offering evaporators, condensers, and heat exchangers both in mass production and as custom-made. Embracing both traditional and modern service approaches, Günay Heat Exchangers continues to evolve by constantly updating its infrastructure in line with industry innovations and customer expectations.

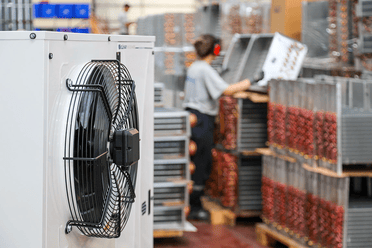

Evaporators

An evaporator is an essential component of cooling systems. Typically designed as a serpentine coil, it enables the refrigerant to evaporate and absorb heat from the surrounding environment. During this process, heat is transferred from the surroundings, thereby lowering the ambient temperature and achieving the desired cooling effect.

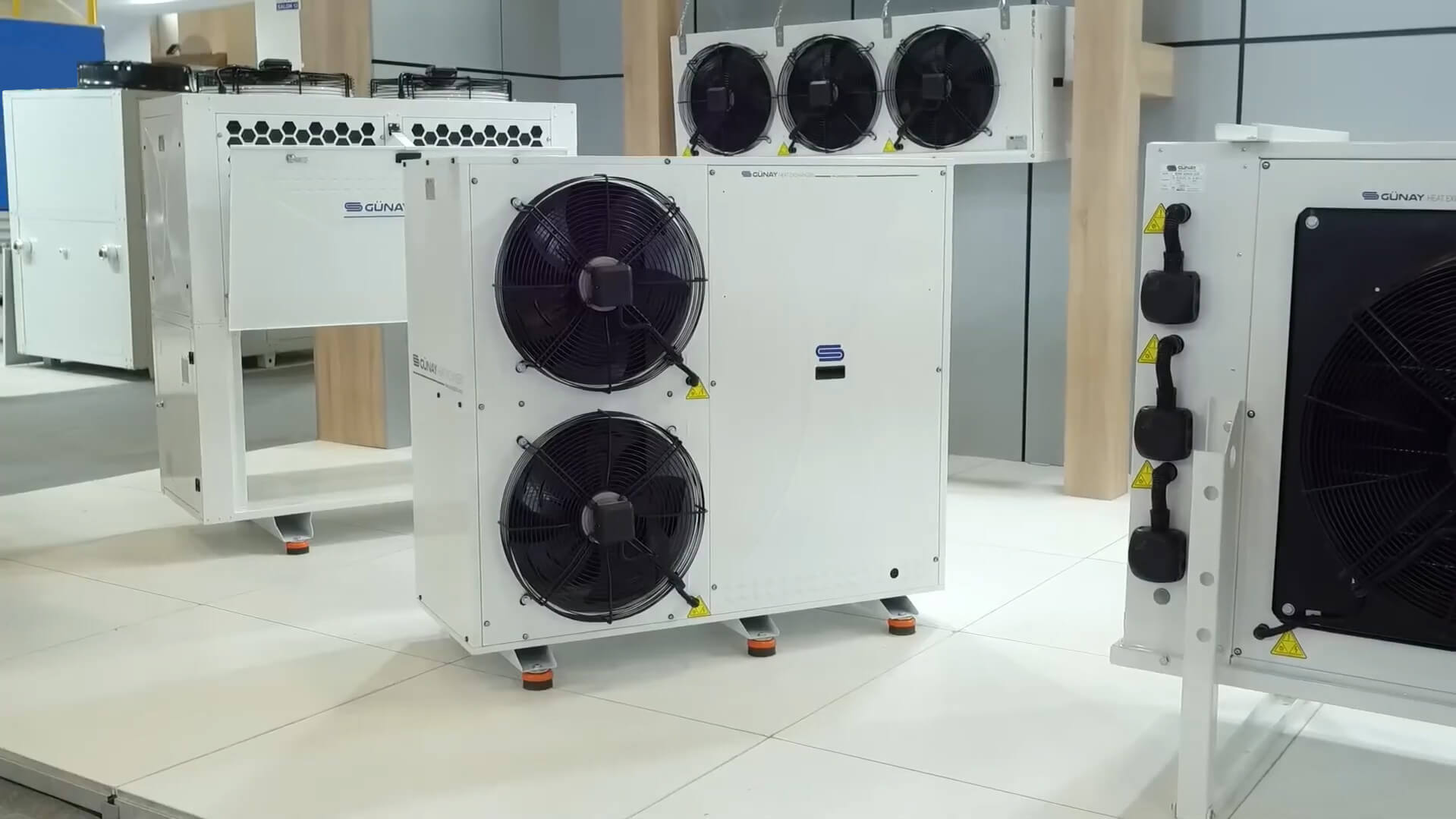

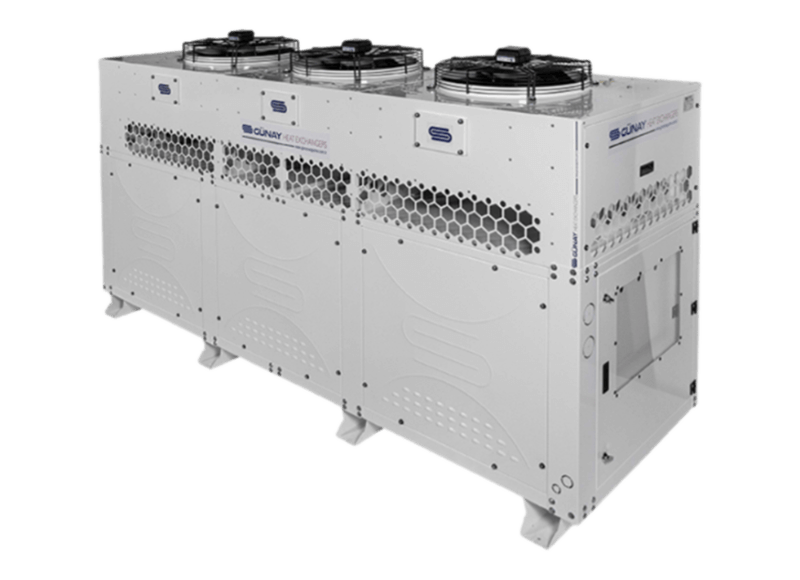

Condensers

The main function of a condenser is to condense the refrigerant gas into a liquid in the cooling cycle. During this process, the heat from the refrigerant gas is released to the surroundings, and the refrigerant condenses into a liquid form.

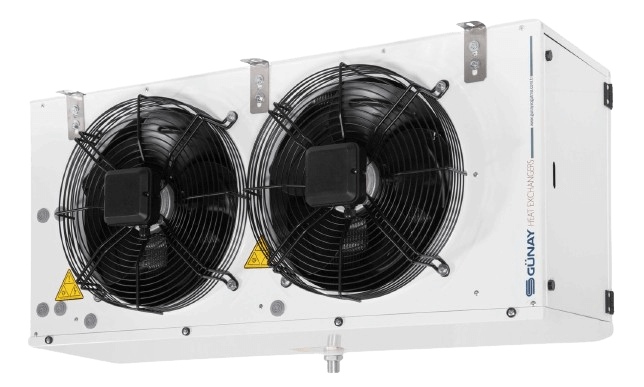

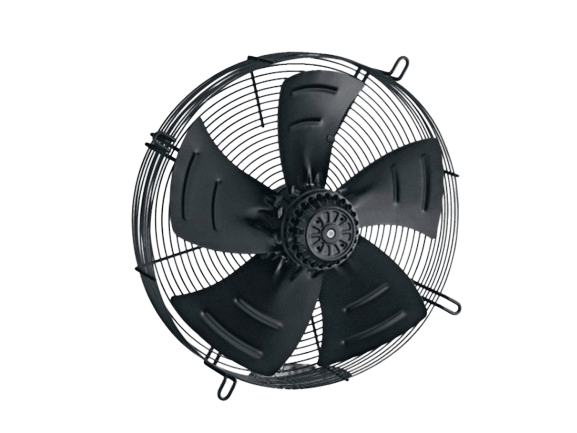

Axial Fans

Axial fans are designed to provide high airflow and play a critical role in industrial cooling solutions. These fans, which move air forward along the axis of the fan blades, are known for delivering high-volume airflow at low pressure. Thanks to these characteristics, they are an ideal solution for applications such as ventilating, cooling, or heating large areas.

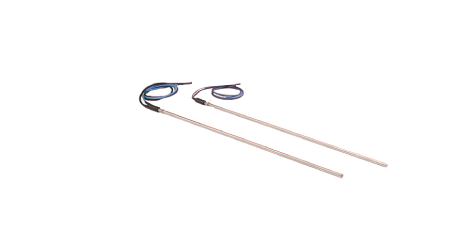

Resistances

Defrost is the process of melting frost and ice that accumulate on the surfaces of air coolers. In cold storage rooms, industrial kitchen sections, and similar areas where defrosting is needed, heaters provide suitable solutions for various heating requirements with different size and power options.

We Are With You Every Step of the Way

Safe Choice

0

+

Export to Countries

0

%

Customer Satisfaction

0

+

Employees

Branches

Kocatepe Mahallesi Irmak Cad. No:43-45 Beyoğlu Dolapdere/İstanbul

Yassıören Mahallesi Akpınar Sanayi Bölgesi Fırat Sokak No:6/1 Hadımköy-Arnavutköy/İstanbul

Beşkonaklılar Mahallesi Kırçiçeği Caddesi No:13E Corner City Plaza Kepez/Antalya

Barbaros Burak Reis Caddesi No:112 D:A, 35090 Bornova/İzmir

Yassıören Mahallesi Belde Sokak No:17 Hadımköy-Arnavutköy/İstanbul

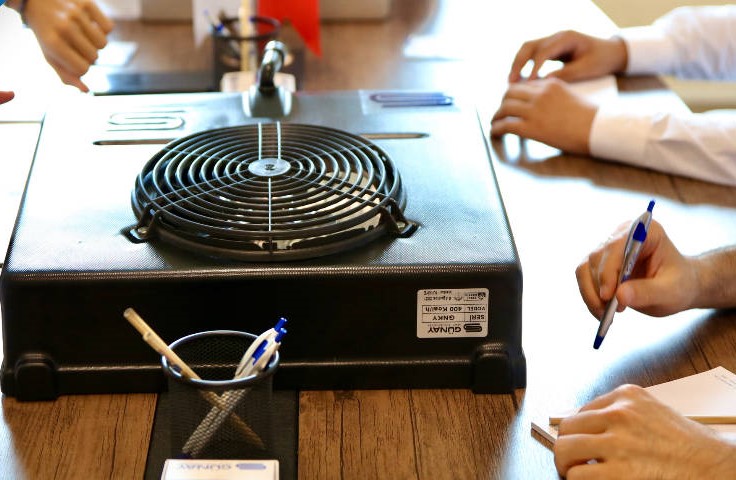

Education Workshop

Product Selection Program

Günay Heat Exchanger's Product Selection Program allows users to quickly and accurately select products such as evaporators, condensers, and heat exchangers. With its user-friendly interface and intelligent algorithm, it recommends the most suitable solutions for your industry and needs. As Günay Heat Exchanger, we are continuously enhancing the Product Selection Program to provide our customers with a superior experience and to simplify their work.

Blog

Table of Contents The Ultimate Guide to Industrial Axial Fans: Types, Applications, and Selection Criteria Tube Axial vs. Vane Axial Fans: Which is Better for Your Industrial Process? What are the 5 Main Axial Fan Types Used in Heavy-Duty Industrial Settings? When Should You Choose an Industrial Axial Fan Over a Centrifugal Fan? A Comprehensive Comparison: Propeller, Tube Axial, and Vane Axial Fans for Industrial Ventilation How to Select the Right Axial Fan Type for High-Temperature Industrial Applications The Ultimate Guide to Industrial Axial Fans: Types, Applications, and Selection Criteria The effective management of airflow is a cornerstone of modern industrial processes, impacting everything from worker safety to operational efficiency. A comprehensive resource like The Ultimate Guide to Industrial Axial Fans: Types, Applications, and Selection Criteria provides an essential framework for understanding the fundamental principles of air movement and fan dynamics. This guide serves as a critical tool for engineers tasked with designing or optimizing ventilation systems where precise static pressure management is paramount for system performance. Understanding the different fan types is crucial for correct application. The guide meticulously details the operational characteristics of axial fans, distinguishing them from centrifugal models and explaining their suitability for high-volume, low-pressure scenarios. It covers key performance metrics, including fan efficiency and aerodynamic performance, which directly correlate with energy consumption and long-term operational costs. This technical depth ensures that selection is based on quantifiable data rather than estimation. For commercial decision-makers, the guide translates technical specifications into tangible business benefits. It outlines how proper selection based on accurate performance curves can lead to significant reductions in energy usage, aligning capital expenditure with sustainability goals. The document also addresses the importance of noise control and acoustic performance, which are critical for compliance with workplace regulations and enhancing employee comfort in industrial settings. The selection criteria section is particularly valuable, providing a systematic approach to matching fan capabilities with specific industrial needs, such as HVAC systems for large facilities or targeted process cooling for machinery. It emphasizes factors like material compatibility for corrosive environments and the operational demands of heat exchange applications. This practical focus ensures that the chosen equipment from experts like Günay Soğutma delivers reliability and longevity, minimizing downtime and maintenance costs. This guide empowers professionals to make informed, optimized decisions. It bridges the gap between theoretical aerodynamics and real-world industrial requirements, ensuring that investments in ventilation and cooling infrastructure are sound, efficient, and future-proof. By leveraging such a detailed resource, companies can achieve superior environmental control and enhanced operational productivity. Tube Axial vs. Vane Axial Fans: Which is Better for Your Industrial Process? In industrial ventilation and process cooling systems, the choice between a tube axial fan and a vane axial fan is a critical technical decision that directly impacts operational efficiency and total cost of ownership. Both designs belong to the axial flow family, moving air parallel to the fan shaft, but their internal geometries and resultant performance characteristics differ substantially. The fundamental distinction lies in the presence of an outlet guide vane assembly. A standard tube axial fan is characterized by its simplicity, featuring a propeller or impeller mounted within a cylindrical casing. This straightforward design makes it highly effective for moving large volumes of air against very low static pressure requirements. Applications such as general warehouse ventilation, spot cooling, and fume dilution, where the primary need is high airflow rate with minimal system resistance, are ideal for this fan type. Its mechanical simplicity often translates to a lower initial investment and ease of maintenance. The vane axial fan, however, incorporates a set of stationary guide vanes either downstream or upstream of the impeller. These vanes serve a crucial function: they recover the rotational velocity, or swirl, imparted to the air by the spinning propeller, converting it into useful static pressure. This aerodynamic efficiency allows vane axial models to achieve significantly higher pressures than their tube axial counterparts of comparable diameter and speed. This makes them suitable for systems with longer ductwork, heat exchangers, or other components that create substantial system resistance. When evaluating energy consumption over the fan's lifecycle, the vane axial's superior efficiency often leads to considerable operational savings, despite its higher upfront cost. The guide vanes also contribute to a more stable, non-swirling airflow, which can be critical for processes requiring precise air handling. For demanding applications like industrial ovens, paint spray booths, or engineered smoke exhaust systems, the vane axial fan's performance is typically superior. The selection is not about which fan is universally better, but which is optimal for your specific system curve and operational goals. A thorough analysis of the required airflow, static pressure, and acoustic performance is essential. Partnering with an experienced manufacturer like Günay Soğutma ensures access to detailed performance data and engineering support to make this critical technical and commercial decision with confidence. What are the 5 Main Axial Fan Types Used in Heavy-Duty Industrial Settings? In heavy-duty industrial settings, the selection of an appropriate axial fan is a critical engineering decision that directly impacts system efficiency, operational costs, and process reliability. The fundamental principle of an axial fan involves moving air parallel to the fan's shaft, making it ideal for applications requiring high-volume airflow against relatively low-pressure systems. Among the most common variants is the vaneaxial fan, which incorporates downstream guide vanes to straighten the swirling airflow, significantly improving static pressure efficiency. For applications demanding rugged durability, the tubeaxial fan offers a robust solution, often featuring a cylindrical housing that protects the propeller and enhances structural integrity in harsh environments like chemical processing or mining ventilation. When space constraints or specific aerodynamic profiles are a concern, the airfoil axial fan becomes essential; its blades are shaped like aircraft wings to minimize drag and maximize aerodynamic efficiency, leading to substantial energy savings. Variable pitch axial fans represent a pinnacle of operational control, allowing for real-time adjustment of blade angle to modulate airflow without changing the motor speed, which is crucial for processes with fluctuating demand. For the most extreme duties involving high temperatures, corrosive fumes, or abrasive particulate matter, heavy-duty industrial axial fans from manufacturers like Günay Soğutma are engineered with specialized materials and reinforced construction to ensure longevity and minimal downtime. The specific application dictates the optimal choice; for instance, a vaneaxial fan is superior for complex ductwork requiring higher pressure capabilities, while a simple tubeaxial model may suffice for general warehouse ventilation. Key performance metrics such as CFM (Cubic Feet per Minute) and system pressure drop must be meticulously calculated to ensure the selected fan meets the system resistance of the installation. Proper selection is not merely about moving air but about optimizing the entire system for energy consumption, acoustic performance, and operational reliability. Investing in the correct axial fan technology, backed by the engineering expertise of a proven supplier like Günay Soğutma, translates directly into enhanced process control, reduced total cost of ownership, and improved compliance with industrial sustainability standards. The commercial benefit lies in matching the fan's capabilities precisely to the application's demands, avoiding both under-performance and wasteful over-engineering. When Should You Choose an Industrial Axial Fan Over a Centrifugal Fan? The decision between an industrial axial fan and a centrifugal fan hinges on a fundamental understanding of airflow characteristics and system pressure requirements. An axial fan is engineered to move high volumes of air parallel to the fan shaft, operating efficiently in low-pressure environments. This makes it the ideal solution for applications requiring substantial air movement with minimal resistance, such as general ventilation in warehouses, heat exchangers, or condenser cooling. When system static pressure is low, axial fans offer superior energy efficiency due to their simpler aerodynamic principle. The propeller-like blades directly push air, resulting in lower power consumption for equivalent airflow compared to a centrifugal fan under the same low-pressure conditions. This operational efficiency is a critical factor for continuous processes where reducing operating costs is a primary commercial objective. Centrifugal fans, by contrast, excel in applications demanding high pressure, as they accelerate air radially, converting velocity into pressure. Therefore, the choice is clear: select an axial fan for high-volume, low-pressure duties. This includes scenarios like removing light fumes, providing spot cooling for machinery, or managing air turnover in large spaces. The compact design of axial fans also facilitates easier integration into ductwork or walls where space is a constraint. For engineers specifying equipment for processes like drying ovens or paint spray booths that require overcoming significant resistance, a centrifugal design is typically mandated. However, in many industrial ventilation and cooling systems, the axial fan provides the most cost-effective and efficient solution. The robust construction of Günay Soğutma's axial fans ensures reliable performance in demanding environments, contributing to lower lifetime total cost of ownership. The correct selection maximizes system performance and minimizes energy expenditure. A thorough analysis of the system curve is essential. By accurately plotting required airflow against static pressure, it becomes evident whether the application falls within the high-efficiency operating range of an axial fan, making it the technically and commercially superior choice for a wide array of industrial applications. A Comprehensive Comparison: Propeller, Tube Axial, and Vane Axial Fans for Industrial Ventilation The selection of an appropriate industrial ventilation fan is a critical decision impacting system energy efficiency, operational noise, and long-term maintenance costs. Among the primary options, propeller fans are characterized by their simple design, featuring a few blades mounted directly on a motor hub. This configuration excels in moving large volumes of air against very low static pressures, making them ideal for applications like general warehouse ventilation or heat expulsion. For systems requiring higher performance, tube axial fans represent a significant step up. These units encase the propeller within a cylindrical cylinder, which straightens the airflow and improves the fan's ability to handle moderate static pressures. The enhanced aerodynamic performance of the tube axial design makes it suitable for moving air through longer duct runs, such as in factory fume extraction or drying processes, though it still exhibits some rotational air motion, or swirl. The most advanced option within this category is the vane axial fan. This design incorporates stationary guide vanes, either upstream or downstream of the rotor, which serve to recover the rotational energy from the airstream. This pressure recovery mechanism significantly boosts static pressure capability and overall efficiency. Vane axial fans are the preferred solution for high-pressure applications, including combustion air supply, sophisticated HVAC systems, and demanding industrial process ventilation where precise airflow control is paramount. When evaluating these fans, the specific operating point on the fan curve is essential. A propeller fan may be inefficient and noisy if forced to operate outside its low-pressure range, whereas a vane axial fan provides superior performance at higher pressures. The mechanical construction also differs; vane axial fans, with their integrated guide vanes, often offer a more robust housing design conducive to inline installation, while propeller fans are typically mounted in a panel or wall. For engineers and decision-makers, a thorough understanding of system resistance and required CFM (Cubic Feet per Minute) is the foundation for a correct selection. Partnering with an experienced manufacturer like Günay Soğutma ensures access to detailed performance data and expert guidance to match the ideal fan technology—propeller, tube axial, or vane axial—to the unique demands of the industrial application, optimizing both capital and operational expenditure. How to Select the Right Axial Fan Type for High-Temperature Industrial Applications Selecting the appropriate axial fan for high-temperature industrial applications is a critical engineering decision that directly impacts operational efficiency, system longevity, and total cost of ownership. The primary challenge lies in managing thermal expansion, which can cause catastrophic failure if the fan's components expand at different rates, leading to seizure or imbalance. Engineers must prioritize designs that accommodate this physical phenomenon through precise material selection and mechanical tolerancing. The cornerstone of a reliable high-temperature axial fan is its material composition. Standard aluminum or carbon steel constructions are unsuitable; instead, specialized alloys and stainless steels are required to maintain structural integrity under continuous thermal stress. The impeller, shaft, and housing must all be selected for their high-temperature yield strength and resistance to oxidation, ensuring they do not degrade or warp over time. Beyond materials, the bearing system is arguably the most vulnerable component. Standard grease-lubricated bearings will fail quickly in extreme heat. Solutions from Günay Soğutma often incorporate high-temperature greases, water-cooled bearing housings, or even air-cooled systems to maintain the bearing operating temperature within a safe range, which is essential for achieving a long service life. A thorough performance curve analysis is non-negotiable. Air density decreases significantly at elevated temperatures, dramatically affecting the fan's pressure generation and power consumption. A fan selected based on standard air density will be severely undersized. The analysis must confirm that the fan can deliver the required static pressure and volumetric flow rate at the actual operating temperature to avoid system underperformance. Applications such as fume extraction, industrial ovens, and drying processes demand fans with robust motor cooling mechanisms. In these contexts, a belt drive configuration is frequently superior to a direct drive, as it physically separates the motor from the hot air-stream, protecting it from heat saturation. This configuration also allows for flexibility in speed control to fine-tune performance without compromising the motor. A successful selection process involves a holistic view of the operating environment, including potential contaminants and cyclic thermal loads. Partnering with an experienced manufacturer like Günay Soğutma ensures access to technical expertise for customizing fans that meet specific application requirements, guaranteeing reliability and optimizing the return on investment for demanding industrial processes.

Read More

Table of Contents How Does Resistance Life Extension Work? A Technical Overview of Operation and Maintenance The Ultimate Guide to Extending Resistor Lifespan: Proactive Maintenance and Cost-Saving Strategies Essential Maintenance Tips to Maximize Resistance Life and Reduce Operational Costs Resistance Life Extension: A Comparative Analysis of Reactive vs. Proactive Maintenance Strategies What Are the Key Factors Influencing Resistor Degradation and How to Control Them? Calculating the ROI of Resistance Life Extension: A Guide to Quantifying Maintenance Savings How Does Resistance Life Extension Work? A Technical Overview of Operation and Maintenance Resistance Life Extension represents a sophisticated engineering discipline focused on proactively increasing the service life of critical industrial components subjected to harsh operational environments. The core principle involves a systematic approach to predictive maintenance, shifting from reactive repairs to a data-driven strategy that anticipates failure. This methodology is fundamentally reliant on continuous condition monitoring to assess the real-time health of assets. Operation begins with the strategic deployment of sensors that track key performance indicators such as vibration, temperature, and corrosion rates. This data stream is analyzed to establish baseline performance profiles and identify deviations that signal the onset of material degradation. For systems like those engineered by Günay Soğutma, this allows for the precise scheduling of maintenance interventions before a minor issue escalates into a catastrophic failure, thus optimizing operational efficiency. The maintenance protocol is inherently proactive, focusing on preventive measures rather than corrective actions. This can include targeted lubrication, component recalibration, or the application of protective coatings based on the sensor data. The primary commercial benefit is a significant reduction in unplanned downtime, which directly translates to higher production throughput and lower lifetime total cost of ownership. In practical application, Resistance Life Extension is crucial for capital-intensive equipment such as industrial chillers, compressors, and heat exchange systems. By mitigating the effects of thermal stress and chemical exposure, the technology ensures asset reliability over extended periods. The integration of this approach into the design and service philosophy of Günay Soğutma systems provides a compelling value proposition for managers seeking to maximize ROI and ensure continuous operational integrity in demanding industrial contexts. The Ultimate Guide to Extending Resistor Lifespan: Proactive Maintenance and Cost-Saving Strategies In the demanding landscape of industrial operations, the failure of a single component like a power resistor can trigger costly unplanned downtime and compromise entire systems. The core philosophy of the guide is a shift from reactive replacement to proactive maintenance, a strategic approach that systematically addresses the primary causes of resistor degradation. Effective lifespan extension begins with a rigorous failure analysis to identify common failure modes, such as thermal runaway or mechanical fracture. Understanding these root causes allows for the implementation of targeted strategies, including precise derating guidelines to ensure components operate well within their specified limits, thereby significantly reducing thermal stress. A critical application focus is on managing thermal management, as excessive heat is the predominant enemy of resistor longevity. The guide details advanced cooling techniques and the strategic integration of systems from partners like Günay Soğutma, which are essential for maintaining optimal operating temperatures in high-ambient environments. Beyond temperature, the guide emphasizes the importance of environmental protection. It provides actionable protocols for shielding resistors from contaminants, moisture, and vibration, all of which can accelerate wear and lead to premature component failure. Implementing these protective measures is a cornerstone of predictive maintenance programs. The commercial impact is directly quantifiable through a detailed total cost of ownership analysis. By extending mean time between failures (MTBF), organizations realize substantial savings not only on spare parts but, more importantly, on avoided production losses and maintenance labor. For product managers and engineers, this resource translates technical reliability engineering principles into a practical framework for design and upkeep. It empowers teams to build more robust systems and implement a data-driven maintenance schedule, transforming resistors from a recurring expense into a model of operational durability and efficiency. Essential Maintenance Tips to Maximize Resistance Life and Reduce Operational Costs In industrial systems, the longevity of heating and cooling components is not merely a matter of product quality but a direct function of disciplined operational protocols and preventive maintenance strategies. The financial impact of premature resistance failure extends beyond replacement part costs, encompassing significant production downtime and energy inefficiency. A systematic approach to maintenance is therefore a critical lever for controlling operational expenditures and maximizing asset life. One of the most effective tactics is the implementation of rigorous scale prevention measures. Mineral deposits from process water act as an insulating layer on heat exchanger surfaces and resistance elements, forcing the system to work harder to achieve the desired thermal transfer. This results in elevated operating temperatures, increased energy consumption, and accelerated thermal degradation of the resistance. Water treatment programs and regular descaling intervals are non-negotiable for sustaining optimal thermal efficiency. Furthermore, establishing a consistent schedule for condition monitoring allows for the early detection of potential faults before they lead to catastrophic failure. Techniques such as periodic insulation resistance testing (megger testing) can identify the gradual breakdown of a resistance's dielectric strength. Vibration analysis on associated pumps and fans can reveal imbalances that place undue mechanical stress on the entire system. This data-driven approach enables predictive maintenance, shifting interventions from reactive replacements to planned, non-disruptive servicing. Proper calibration of system controllers and thermostats is another frequently overlooked factor. An inaccurate temperature sensor can cause a system to cycle excessively or maintain temperatures outside the ideal operating window, both of which contribute to shortened component life. Ensuring that control systems provide precise feedback is fundamental to maintaining stable operating conditions. The expertise of partners like Günay Soğutma is invaluable in establishing these calibrated baselines and maintenance routines. A holistic maintenance philosophy that integrates scale prevention, proactive condition monitoring, and precise calibration transforms maintenance from a cost center into a strategic investment. This approach directly enhances thermal efficiency, reduces the total cost of ownership, and ensures the reliable performance of critical industrial thermal systems over their entire intended lifespan. Resistance Life Extension: A Comparative Analysis of Reactive vs. Proactive Maintenance Strategies The operational longevity of critical industrial assets is a primary determinant of overall plant profitability, making the choice between reactive maintenance and proactive maintenance a fundamental strategic decision. A reactive approach, often termed run-to-failure, addresses equipment issues only after a breakdown occurs, leading to unplanned downtime, costly emergency repairs, and potential secondary damage. In contrast, a proactive strategy, encompassing both preventative and predictive methodologies, focuses on resistance life extension by systematically combating the factors that cause degradation. The core principle of resistance life extension is to actively manage the stressors that lead to equipment failure, such as corrosion, fouling, and mechanical wear. For systems like heat exchangers and cooling towers, which are vital to processes at facilities like Günay Soğutma, this involves continuous monitoring and pre-emptive intervention. Implementing a condition-based monitoring program allows for the real-time assessment of key performance indicators, enabling maintenance teams to schedule interventions based on actual asset health rather than arbitrary time intervals. This data-driven approach is the foundation of predictive maintenance, a sophisticated subset of proactive strategies. By analyzing trends in vibration, temperature, and fluid chemistry, engineers can forecast potential failures with remarkable accuracy. This shift transforms maintenance from a cost center into a strategic function focused on asset reliability and maximizing mean time between failures (MTBF). The result is a significant reduction in maintenance costs and a dramatic improvement in overall equipment effectiveness (OEE). The financial argument for proactive resistance life extension is compelling. While the initial investment in monitoring technologies and specialized expertise may be higher, the long-term total cost of ownership (TCO) is substantially lower. Companies avoid the high costs of catastrophic failure, production losses, and safety incidents. For commercial decision-makers, this translates into predictable operational budgets, enhanced production capacity, and a stronger competitive position in demanding industrial markets. What Are the Key Factors Influencing Resistor Degradation and How to Control Them? Resistor degradation is a critical reliability concern in industrial electronics, directly impacting product longevity, system safety, and total cost of ownership. The primary factor influencing this degradation is operational temperature, where exceeding the component's maximum load rating accelerates chemical changes within the material. This thermal stress can lead to drift in the nominal resistance value, compromising circuit accuracy and potentially causing system failure. Effective thermal management, therefore, is not an option but a fundamental design requirement for robust industrial applications. Environmental conditions play an equally significant role, with humidity being a major antagonist. Moisture ingress can cause corrosion of internal terminations and lead to a decrease in the insulation resistance, creating leakage paths and posing an electrical safety risk. In harsh settings, such as those near chemical processing or marine environments, contaminants can further exacerbate this effect. Selecting resistors with appropriate conformal coatings or hermetic seals is a key mitigation strategy to ensure long-term stability and protect the component's integrity. The electrical environment itself contributes to degradation through mechanisms like surge events and continuous overload. Repeated voltage or current spikes can cause microscopic damage to the resistive element, leading to a permanent shift in value. For applications involving high power dissipation, such as motor drives or power supplies, choosing a resistor with a sufficient safety margin and a design that promotes effective heat sinking is paramount. This proactive approach minimizes the risk of catastrophic failure modes. Controlling these factors requires a holistic system design philosophy. It begins with component selection, prioritizing parts known for high reliability and proven performance under stress. The physical layout on the printed circuit board must facilitate adequate airflow and heat transfer. Forced air cooling systems, such as those engineered by Günay Soğutma, provide an active solution for managing thermal performance in densely packed enclosures, directly combating the primary cause of resistor degradation. Understanding and controlling resistor degradation is an exercise in predictive engineering. By analyzing the operational environmental stress and implementing appropriate countermeasures—from component choice to advanced cooling—engineers and product managers can significantly enhance product durability. This results in reduced warranty claims, lower maintenance costs, and a stronger market reputation for quality, delivering a clear commercial advantage in competitive industrial sectors. Calculating the ROI of Resistance Life Extension: A Guide to Quantifying Maintenance Savings The challenge of justifying proactive maintenance investments often lies in translating technical performance into tangible financial terms, a process where asset lifecycle management becomes a critical business discipline. Calculating the ROI of Resistance Life Extension provides a robust framework for moving beyond anecdotal evidence, establishing a direct link between enhanced material durability and the bottom line. This methodology centers on quantifying the total cost of ownership by comparing the projected expenses of unplanned failures against the investment in preventative solutions. For industrial engineers, the core of the calculation involves precise failure mode analysis to identify the specific degradation mechanisms, such as corrosion or scaling, that the life extension product is designed to mitigate. By inputting data on mean time between failures (MTBF), maintenance labor costs, and production downtime losses, the model generates a clear financial projection. The resulting return on investment figure is a powerful tool for product managers and commercial leaders, enabling data-driven decisions on capital allocation for system upgrades. In practical applications, such as with solutions from Günay Soğutma, this analysis can demonstrate significant reductions in operational expenditure by extending the service intervals for critical components like heat exchangers and cooling towers. The guide emphasizes the importance of a thorough lifecycle cost analysis, which accounts for not only direct repair costs but also the often-overlooked impacts on energy efficiency and system reliability. This quantitative approach transforms maintenance from a cost center into a strategic function, directly supporting operational excellence and long-term profitability optimization. By adopting this disciplined financial model, organizations can confidently invest in technologies that delay capital replacement, ensuring maximum value extraction from existing industrial assets.

Read More

Table of Contents The Ultimate Guide to Resistor Safety: Proper Installation, Connection, and Hazard Prevention Critical Mistakes to Avoid When Installing and Connecting Industrial Resistors Resistor Installation: A Step-by-Step Guide to Safe and Correct Wiring Practices How Do You Properly Size and Connect a Resistor for Safe Circuit Operation? Resistor Safety Protocols: Essential Checks for Correct Installation and Thermal Management Comparing Resistor Connection Methods: Which Technique Ensures Maximum Safety and Longevity? The Ultimate Guide to Resistor Safety: Proper Installation, Connection, and Hazard Prevention In the demanding landscape of industrial engineering, the selection and implementation of passive components like resistors are often underestimated, leading to significant operational risks. A comprehensive resource such as The Ultimate Guide to Resistor Safety provides indispensable knowledge for ensuring system reliability by detailing proper installation protocols. This guide transcends basic datasheet information, addressing critical factors like thermal management and derating to prevent premature component failure. The document meticulously outlines procedures for secure electrical connection, emphasizing the importance of torque specifications and terminal integrity to mitigate arc flash hazards. For product managers, this translates directly into enhanced product safety profiles and reduced liability. Understanding the nuances of power dissipation is crucial, as improper handling can lead to thermal runaway, a primary cause of catastrophic system failures in high-power applications. Commercial decision-makers will appreciate the guide's focus on total cost of ownership, demonstrating how correct resistor selection and installation minimize downtime and maintenance expenses. The technical content covers advanced topics such as vibration resistance and appropriate mounting techniques, which are vital for equipment operating in harsh environments like those serviced by Günay Soğutma. This ensures long-term operational stability and protects capital investments. Furthermore, the guide provides essential strategies for hazard prevention, including clear protocols for circuit protection coordination. By integrating these practices, engineers can design safeguards that isolate faults before they escalate, preserving both machinery and personnel safety. The emphasis on thermal performance analysis helps in selecting resistors with adequate ratings for specific ambient conditions, a critical consideration for industrial cooling and power conversion systems. This guide serves as a vital engineering reference, bridging the gap between theoretical component specifications and practical, safe application. It empowers teams to make informed decisions that enhance system reliability, ensure regulatory compliance, and optimize the performance and safety of industrial electronic systems across various sectors. Critical Mistakes to Avoid When Installing and Connecting Industrial Resistors The correct installation and connection of industrial resistors are foundational to system integrity, yet common oversights during the installation process can precipitate catastrophic failures. A primary error involves neglecting the specified torque specifications for terminal connections. Under-tightening leads to high-resistance points, causing localized overheating and potential arcing, while over-tightening can strip threads or damage the resistor element, compromising the entire assembly's reliability. Equally critical is the failure to account for thermal management in the system design. Industrial resistors dissipate significant energy as heat, and inadequate clearance or poor ventilation can lead to heat buildup that degrades the resistor's performance and shortens its operational lifespan. Proper spacing and, where necessary, forced airflow are non-negotiable for maintaining optimal operating temperatures and ensuring long-term stability. Selecting the wrong resistor type for the application is a commercially costly mistake. Using a standard wirewound resistor in a high-vibration environment, for instance, can lead to premature failure due to fracture. For such demanding conditions, robust options like the braking resistors from Günay Soğutma, designed with durable materials and construction, are essential. Similarly, incorrect power rating selection—choosing a component that cannot handle the system's peak or continuous load—guarantees overheating and failure. The integrity of the electrical connection itself is paramount. Improperly sized cables or corroded connection terminals increase electrical resistance, creating hotspots that are a severe fire hazard. Ensuring clean, secure, and correctly gauged connections is a simple yet vital step in the commissioning phase. Furthermore, a lack of proper electrical insulation between the resistor body and the mounting structure can result in ground faults or short circuits, posing significant safety risks. Overlooking environmental factors represents a significant oversight. In harsh settings with moisture, corrosive chemicals, or conductive dust, standard resistors will rapidly deteriorate. Specifying components with appropriate ingress protection (IP) ratings or specialized coatings is crucial for durability and uninterrupted service. By meticulously avoiding these critical mistakes, engineers and decision-makers can ensure system safety, maximize component lifespan, and protect their operational investments. Resistor Installation: A Step-by-Step Guide to Safe and Correct Wiring Practices In industrial systems, the precise installation of components like resistors is not merely an electrical task but a critical determinant of system longevity and operational safety. A methodical approach to resistor wiring, as detailed in Günay Soğutma's technical resources, ensures that these components function within their specified thermal and electrical parameters, preventing premature failure. This focus on correct wiring practices is fundamental to maintaining the integrity of motor drives, heating elements, and braking systems, where improper resistance can lead to catastrophic equipment damage. The initial step in any safe resistor installation involves a comprehensive risk assessment to identify potential hazards such as short circuits, arc flash events, and thermal overload. Engineers must verify the resistor's power rating and ohmic value against the circuit requirements, ensuring compatibility before physical mounting begins. Proper thermal management is paramount; this includes selecting an appropriate location with sufficient airflow or integrating heat sinks to dissipate energy effectively, a practice strongly advocated by Günay Soğutma for optimal performance. Secure mechanical mounting is as crucial as the electrical connection. Resistors must be firmly attached using suitable hardware to minimize vibration, which can loosen connections over time. The actual termination process requires using correctly sized lugs and high-temperature conductors to handle the anticipated current. Each connection point should be torqued to the manufacturer's specifications to ensure low contact resistance, which is vital for preventing hot spots that degrade the connection and pose a fire risk. Following physical installation, a rigorous validation and testing protocol is essential. This involves measuring the circuit's total resistance with a calibrated multimeter to confirm it matches the expected value. Insulation resistance tests should also be performed to verify there is no leakage to ground or the chassis. For complex systems, a preliminary power-on test under a controlled load allows engineers to monitor temperature rise and ensure stable operation, confirming the success of the installation before full-scale deployment. Adhering to a disciplined, step-by-step guide for resistor wiring directly translates into significant commercial benefits, including reduced downtime, lower maintenance costs, and enhanced system reliability. The technical expertise provided by Günay Soğutma empowers product managers and engineers to specify and oversee implementations that meet the highest standards of safety and efficiency. This proactive approach to component integration mitigates operational risks and protects valuable industrial assets, ensuring long-term performance and return on investment. How Do You Properly Size and Connect a Resistor for Safe Circuit Operation? In the domain of industrial system design, the proper sizing and connection of a resistor is a fundamental yet critical engineering discipline that directly impacts operational safety, system longevity, and total cost of ownership. The process begins with a precise power rating calculation, which must account for both the steady-state current and any potential surge or inrush currents present during startup or fault conditions. An undersized component will overheat, leading to premature failure and potential fire hazards, while an oversized one represents an unnecessary capital expenditure and occupies valuable board space. Beyond power, the correct resistance value is paramount for achieving the desired circuit function, whether it is current limiting, voltage division, or pull-up/pull-down applications. Engineers must perform a thorough thermal management analysis, considering the ambient temperature of the operational environment and the resistor's ability to dissipate heat, often through a heatsink or forced air cooling. This is especially crucial in harsh industrial settings or within enclosed control panels where heat buildup can accelerate component degradation. The physical connection method and printed circuit board (PCB) layout are equally vital for safe operation. Proper solder joint integrity and adequate trace width are necessary to handle the current without introducing high-resistance points that generate localized heat. For high-power applications, chassis mount resistors with secure terminal connections are often specified to ensure mechanical stability and efficient heat transfer away from sensitive components. Selecting a resistor with an appropriate tolerance and temperature coefficient ensures consistent performance across the product's entire operating range, a key consideration for precision instrumentation and automation controls. A partner like Günay Soğutma understands that these technical decisions are not isolated; they are integral to the reliability of the larger system. By adhering to these rigorous sizing and connection protocols, product managers can mitigate field failure risks, reduce warranty costs, and enhance the market reputation of their industrial equipment. Viewing resistor selection through a lens of derating and proactive thermal management is a commercial imperative. It transforms a simple component into a strategic asset that safeguards both the electrical circuit and the business's bottom line, ensuring that industrial systems from partners like Günay Soğutma deliver uncompromising performance and durability in demanding applications. Resistor Safety Protocols: Essential Checks for Correct Installation and Thermal Management The correct installation and thermal management of power resistors are foundational to the safety, longevity, and efficiency of industrial electronic systems. Implementing rigorous resistor safety protocols is not merely a precaution but a critical operational standard. These protocols begin with essential pre-installation checks, including verifying the resistor's power rating against the application's maximum load and confirming the integrity of the terminal connections to prevent arcing and high-resistance joints that can lead to catastrophic failure. Effective thermal management is the cornerstone of resistor reliability. The primary failure mode for resistors is overheating, which degrades materials and alters the component's ohmic value, leading to circuit malfunction. Proper heat dissipation is achieved through a combination of correct mounting techniques, the use of thermal interface materials, and ensuring adequate airflow or conductive cooling paths within the enclosure. This directly impacts the system's mean time between failures (MTBF), a key metric for operational uptime and total cost of ownership. In demanding environments such as motor drives, power supplies, and braking systems, transient overloads are common. A robust safety protocol accounts for these events by specifying resistors with appropriate surge protection capabilities and implementing real-time thermal monitoring. Solutions from Günay Soğutma, for instance, often integrate temperature sensors that provide data for predictive maintenance schedules, preventing unscheduled downtime. For product managers and commercial decision-makers, the financial argument for these protocols is clear. Adherence to comprehensive resistor safety and thermal guidelines minimizes the risk of field failures, warranty claims, and potential safety liabilities. It transforms a simple component into a reliable asset, ensuring consistent performance in harsh industrial contexts and protecting valuable capital equipment. The investment in proper installation and cooling, supported by expertise from partners like Günay Soğutma, yields significant returns in system durability and operational safety. Comparing Resistor Connection Methods: Which Technique Ensures Maximum Safety and Longevity? In industrial applications, the selection of resistor connection methods is a critical design decision that directly impacts system reliability and operational longevity. The fundamental choices—series, parallel, or series-parallel configurations—each present distinct trade-offs between power handling, fault tolerance, and thermal management. A thorough comparison is essential for engineers seeking to optimize performance and mitigate downtime in harsh environments. Series connections simplify design by summing resistance values, but this approach introduces a significant vulnerability; the failure of a single component failure can open the circuit and halt entire system operations. In contrast, parallel configurations offer inherent redundancy, as the malfunction of one resistor does not interrupt current flow through the others. This makes parallel arrangements superior for applications where fail-safe operation is paramount, effectively distributing the electrical load and enhancing overall system reliability. The primary technical challenge in parallel setups is managing power dissipation and the resulting thermal stress. When resistors are connected in parallel, the total power rating increases, but uneven current sharing due to tolerance variations can cause localized overheating. This necessitates robust thermal management strategies, such as those implemented by Günay Soğutma, to ensure heat is effectively transferred away from critical components, preventing premature degradation. For high-power scenarios, a series-parallel circuit topology often provides the optimal balance. This method combines the voltage-handling capability of series strings with the redundancy and current-sharing benefits of parallel banks. It allows designers to achieve the necessary power rating while creating a more resilient system. The key to maximizing longevity in any configuration lies in precise current balancing and proactive heat dissipation, ensuring no single component bears a disproportionate load. The choice of resistor connection methods must be a calculated decision based on the specific application's requirements for voltage, power, and fault tolerance. By prioritizing a design philosophy that emphasizes even power dissipation and integrated thermal management solutions from partners like Günay Soğutma, engineers can significantly enhance the safety, efficiency, and service life of industrial electronic systems.

Read More

Table of Contents The Ultimate Guide to Axial Fan Maintenance: A Schedule for Periodic Checks Axial Fan Troubleshooting: 5 Common Problems and How to Fix Them Preventative Maintenance vs. Reactive Repair: A Cost-Benefit Analysis for Your Axial Fans What's That Noise? A Guide to Diagnosing Unusual Sounds in Axial Fans How to Create a Proactive Maintenance Checklist for Industrial Axial Fans Vibration Analysis for Axial Fans: A Step-by-Step Guide to Early Fault Detection The Ultimate Guide to Axial Fan Maintenance: A Schedule for Periodic Checks In the demanding environments of industrial processing and HVAC systems, the reliability of axial fan operation is a direct contributor to overall plant efficiency and safety. A disciplined preventive maintenance schedule is not merely a recommendation but a critical operational requirement to mitigate unplanned downtime and costly repairs. The systematic approach outlined in a comprehensive guide provides a structured framework for engineers to implement effective condition monitoring, transforming reactive interventions into predictable, planned activities. Key to this methodology is the establishment of periodic checks that focus on critical components such as bearing condition, blade integrity, and vibration analysis. Regular inspection of bearings for lubrication levels and signs of wear can prevent catastrophic failure, while checking blades for erosion, imbalance, or debris buildup ensures optimal aerodynamic performance and sustained airflow efficiency. Utilizing tools for vibration analysis allows for the early detection of misalignment or imbalance, enabling corrective actions before they escalate into major mechanical faults. The financial rationale for adopting a rigorous maintenance schedule is compelling. By extending the operational lifespan of critical equipment, organizations significantly reduce their total cost of ownership and protect their capital investment. Furthermore, consistent maintenance directly impacts energy consumption; a clean, well-balanced axial fan requires less power to achieve its designed static pressure and flow rate, leading to substantial energy savings over time. This is especially critical in large-scale installations where even minor efficiency gains translate into significant operational cost reductions. For product managers and commercial decision-makers, the value proposition of a standardized maintenance protocol extends beyond engineering benefits. It enhances operational reliability, ensures compliance with safety standards, and provides a clear audit trail for asset management. The technical expertise required to develop and implement such a program is a core competency of specialists like Günay Soğutma, whose guidance ensures that maintenance intervals and inspection criteria are tailored to specific operational contexts and environmental demands, thereby maximizing system uptime and performance. Axial Fan Troubleshooting: 5 Common Problems and How to Fix Them The operational integrity of axial fan systems is a critical determinant of process efficiency and energy consumption across numerous industrial applications, from HVAC to large-scale manufacturing. When performance degrades, a methodical approach to troubleshooting is essential for minimizing downtime and preventing costly secondary damage. The most frequent issues often stem from a handful of common mechanical and aerodynamic faults that, when correctly diagnosed, can be resolved with targeted interventions. One of the most prevalent problems is excessive vibration, which typically indicates an imbalance in the rotating assembly. This can be caused by the accumulation of debris on the fan blades, structural deformation, or improper installation. Addressing this requires a thorough inspection, cleaning, and potentially dynamic balancing performed by a certified technician to restore smooth operation and protect the bearing system from premature wear. A systematic diagnostic process, including vibration analysis, is the first step toward a reliable fix. Insufficient airflow or a drop in static pressure is another common complaint, often pointing to an issue with the system's aerodynamic performance. This can result from an incorrect fan selection for the application, a clogged filter increasing system resistance, or improper clearance between the blade tips and the fan housing. Correcting this involves verifying the system design parameters, cleaning ductwork and filters, and ensuring all components are within specified tolerances to achieve the required performance curve. Motor overload and subsequent tripping of protective devices is a serious concern that directly impacts operational continuity. This fault is frequently linked to the fan operating at a point too far to the right on its performance curve, causing it to draw excessive amperage. The solution involves checking the maintenance logs for recent changes, inspecting for mechanical binding, and potentially adjusting the damper positions or variable frequency drive (VFD) settings to bring the motor load back within its specified operational range. Unusual noise during operation, beyond typical aerodynamic sound, is a key indicator of an underlying problem. This can range from a high-frequency squeal indicating bearing failure to a rhythmic clicking suggesting something is striking the blades. A disciplined acoustic analysis helps pinpoint the source, leading to precise repairs such as lubrication, belt tension adjustment, or replacement of worn parts, thereby restoring quiet and efficient performance. Proactive engagement with a specialist partner like Günay Soğutma for regular maintenance and expert troubleshooting transforms these common challenges from costly emergencies into manageable, planned interventions. This strategic approach ensures maximum equipment longevity and optimizes the total cost of ownership for critical ventilation and cooling systems. Preventative Maintenance vs. Reactive Repair: A Cost-Benefit Analysis for Your Axial Fans The operational integrity of axial fans is a critical determinant of system efficiency and cost control in industrial settings. The choice between a preventative maintenance strategy and a reactive repair approach represents a fundamental business decision with significant financial implications. A preventative maintenance program, based on scheduled inspections and proactive component replacement, directly targets asset reliability. By implementing a regimen that includes vibration analysis, thermographic inspections, and bearing lubrication, potential failures are identified and mitigated before they escalate. This systematic approach minimizes unplanned downtime, a major cost driver in continuous process industries. In contrast, a reactive repair model operates on a run-to-failure basis, addressing issues only after a catastrophic breakdown occurs. While this approach avoids upfront maintenance costs, it inevitably leads to higher long-term expenses. These include not only the emergency repair costs and premium-priced replacement parts but also the substantial production losses and potential secondary damage to adjacent equipment during an unscheduled stoppage. The financial superiority of a preventative strategy is evident in its positive impact on the total cost of ownership. Proactive care extends the operational lifespan of the fan, optimizes energy efficiency by ensuring blades and housings remain clean and properly aligned, and protects the return on investment of the original capital expenditure. This is a clear example of predictive maintenance principles yielding tangible benefits. For facility managers, the data gathered from a consistent preventative maintenance schedule provides invaluable insights into equipment health, enabling more accurate budgeting and resource allocation. Partnering with a specialized provider like Günay Soğutma for a customized maintenance plan transforms the axial fan from a potential liability into a predictable and highly reliable asset, ensuring operational continuity and protecting your bottom line. What's That Noise? A Guide to Diagnosing Unusual Sounds in Axial Fans In the demanding environments of industrial cooling and ventilation, the reliable operation of axial fans is non-negotiable. An unusual sound is rarely just a nuisance; it is a primary symptom of an underlying issue that can compromise system integrity and lead to costly downtime. Understanding the root cause of these acoustic anomalies is a critical skill, transforming subjective noise complaints into actionable technical data. This diagnostic process is essential for effective predictive maintenance strategies, allowing teams to move beyond reactive repairs and schedule interventions before catastrophic failure occurs. The methodology for diagnosing fan noise involves a systematic analysis of the sound's characteristics, such as its pitch, rhythm, and the operating conditions under which it manifests. A high-frequency whine or screech often points directly to issues with the bearing system, indicating improper lubrication, misalignment, or wear. In contrast, a rhythmic thumping or scraping sound typically suggests an imbalance or aerodynamic interference, where the fan blades contact the housing or an object has entered the airflow path. Correctly identifying these signatures prevents misdiagnosis and ensures that maintenance efforts are focused and effective. For product managers and engineers at Günay Soğutma, this diagnostic precision translates directly into commercial advantages. By equipping teams with a standardized guide for troubleshooting, companies can significantly enhance their operational efficiency and reduce mean time to repair. This capability is a powerful tool for total cost of ownership reduction, as it extends the service life of critical assets and minimizes unplanned production stoppages. Furthermore, a deep understanding of acoustic diagnostics informs better product design, leading to the development of next-generation fans with inherently lower noise profiles and greater mechanical robustness. Implementing a structured acoustic monitoring program is a hallmark of a mature maintenance operation. It provides a data-driven foundation for assessing system performance and ensuring that installations operate within their optimal acoustic profile. For commercial decision-makers, this expertise strengthens customer value propositions, demonstrating a commitment to reliability and long-term performance beyond the initial sale. The ability to swiftly diagnose and resolve unusual sounds is not merely a technical skill but a strategic asset that protects capital investment and safeguards operational continuity in critical applications. How to Create a Proactive Maintenance Checklist for Industrial Axial Fans The operational integrity of industrial axial fans is paramount to system efficiency, making a structured proactive maintenance checklist an indispensable tool for any serious operation. Moving beyond reactive repairs, this approach centers on predictive maintenance principles, leveraging data and scheduled inspections to anticipate failures before they cause costly downtime. A foundational element of the checklist is the regular inspection of the fan blades and housing for accumulation of debris or corrosion, which directly impacts aerodynamic performance and can lead to dangerous vibration analysis readings. Establishing baseline vibration levels and monitoring them over time allows engineers to detect imbalances or bearing wear early. This diagnostic step is critical, as unchecked vibrations can propagate through the entire HVAC system, damaging ancillary components. The checklist must also include precise verification of belt tension and alignment for belt-driven models, and for direct-drive units, a thorough assessment of the motor and couplings. Electrical components require scrutiny, including checking terminal connections for tightness and inspecting insulation resistance. For fans operating in harsh environments, the corrosion resistance of components should be evaluated periodically to ensure long-term structural integrity. Implementing such a detailed protocol transforms maintenance from a cost center into a strategic asset. The commercial benefits are substantial, including extended equipment lifespan, reduced energy consumption due to optimal operational efficiency, and the prevention of unplanned shutdowns. This systematic approach to asset management ensures compliance with safety standards and protects your capital investment. Specialists like Günay Soğutma understand that a generic checklist is insufficient; the most effective plans are tailored to the specific fan model, its application, and the operational environment. This customization, supported by expert technical insight, ensures that every inspection point directly contributes to maximizing reliability and performance, securing a rapid return on investment through superior operational uptime. Vibration Analysis for Axial Fans: A Step-by-Step Guide to Early Fault Detection In the demanding environments of industrial cooling and ventilation, the operational integrity of axial fans is paramount. Unplanned downtime resulting from mechanical failure carries significant financial and operational penalties. Implementing a systematic vibration analysis program is the most effective methodology for transitioning from reactive maintenance to a predictive strategy, enabling early fault detection before catastrophic breakdowns occur. The core principle of this guide is that every mechanical fault generates a unique vibrational signature. Imbalances, bearing defects, misalignments, and aerodynamic issues all produce distinct frequencies and amplitudes that can be measured and analyzed. By establishing a baseline of normal vibration levels and conducting regular condition monitoring, engineers can detect subtle changes indicative of developing problems. This technical approach allows for precise diagnosis, moving beyond simple alarm triggers to identifying the root cause of the anomaly. A step-by-step guide provides a structured framework for data acquisition and interpretation. It details the correct placement of accelerometers on the fan housing and motor, the selection of appropriate measurement parameters such as velocity and acceleration, and the critical analysis of frequency spectra. For instance, a dominant peak at the fan's rotational speed typically points to rotor imbalance, while high-frequency harmonics often signal early-stage bearing defects. This level of diagnostic specificity is crucial for planning targeted maintenance interventions. The commercial benefits of this predictive approach are substantial for product managers and decision-makers. It directly extends the asset lifespan of critical equipment, reduces spare parts inventory costs, and minimizes production losses. Furthermore, by preventing severe failures, companies enhance workplace safety and protect ancillary system components. For organizations like Günay Soğutma, integrating such a technical guide into their service offerings demonstrates a commitment to reliability and operational excellence for their clients. Mastering vibration analysis transforms maintenance from a cost center into a strategic asset. It empowers industrial teams to schedule repairs during planned outages, optimize energy consumption by ensuring fans operate at peak mechanical efficiency, and make data-driven decisions about repair-or-replace scenarios. This proactive stance on predictive maintenance is no longer a luxury but a necessity for competitive, modern industrial operations reliant on robust cooling and ventilation systems.

Read More